USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 2/TASK 2

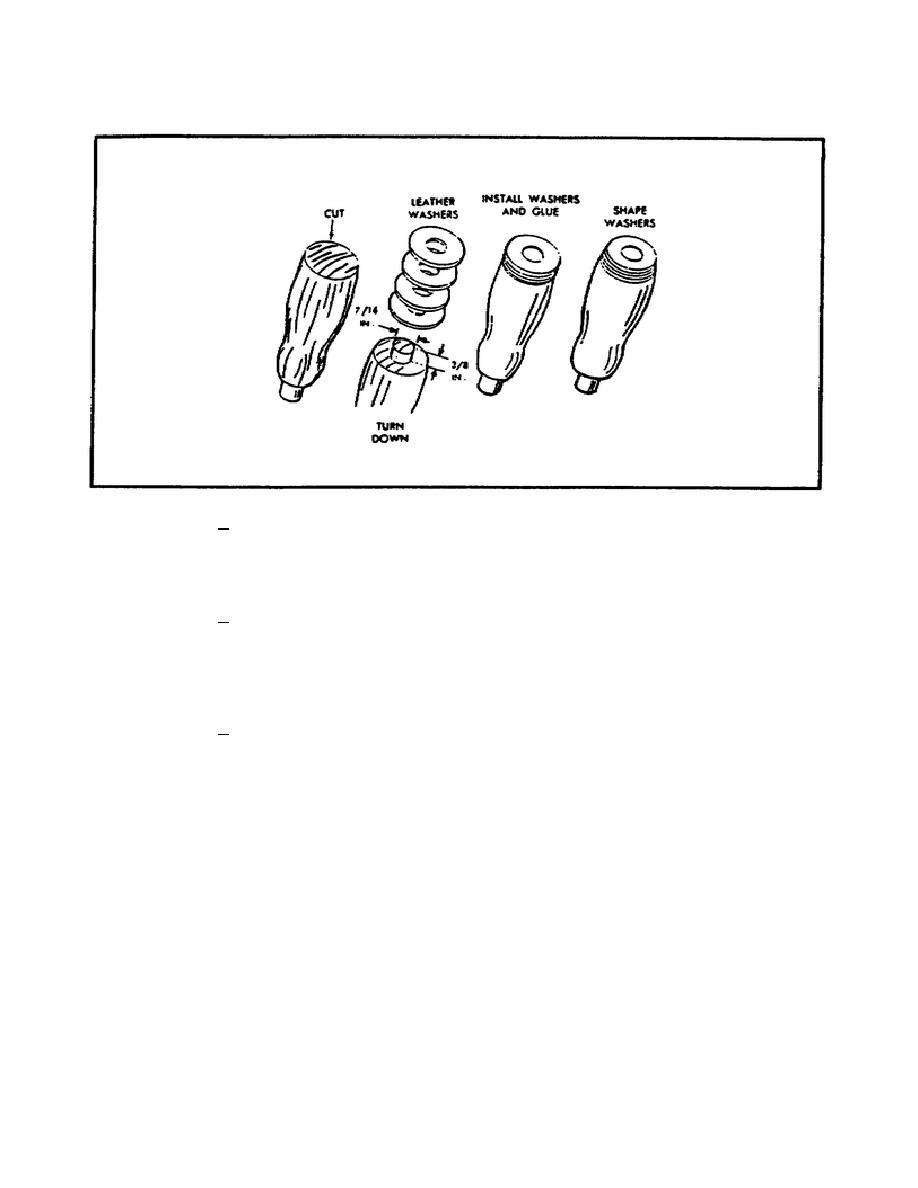

FIGURE 92.

REPAIRING MUSHROOMED HANDLE.

4 After the glue dries, reshape the handle end by cutting and

sanding the washers to conform to the original rounded shape.

(d) Replacing Broken Handle.

1 If a socket-type handle is

damaged beyond repair or is

broken off in the socket, remove the handle,

drilling out the broken ends

from the socket if necessary.

Shape a new

handle to fit snugly in the

socket. Secure the blade in a soft-jawed vise

and tap the handle to seat in

the socket.

2 If a tang-end type handle is damaged beyond repair, or is

split, remove the handle. Select a new handle to fit the tang and chisel.

Fit a ferrule on the handle by tapping with a soft-faced mallet.

Prick

punch ferrule to handle and insert the tang in the handle. Tap the back end

of the handle on a flat surface until the chisel is properly seated.

(2) Machinist's and Blacksmith's Chisels.

(a) Grinding.

Grind chisels of this type immediately when they

become dull. Most of these chisels have two bevels, which form the cutting

edge.

The included angle formed by the two bevels should be as small as

possible without leaving the cutting edge weak. If the angle is too small,

the chisel will soon become dull; if the angle is too large, more force will

be required to drive the

119

Previous Page

Previous Page