USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 2/TASK 2

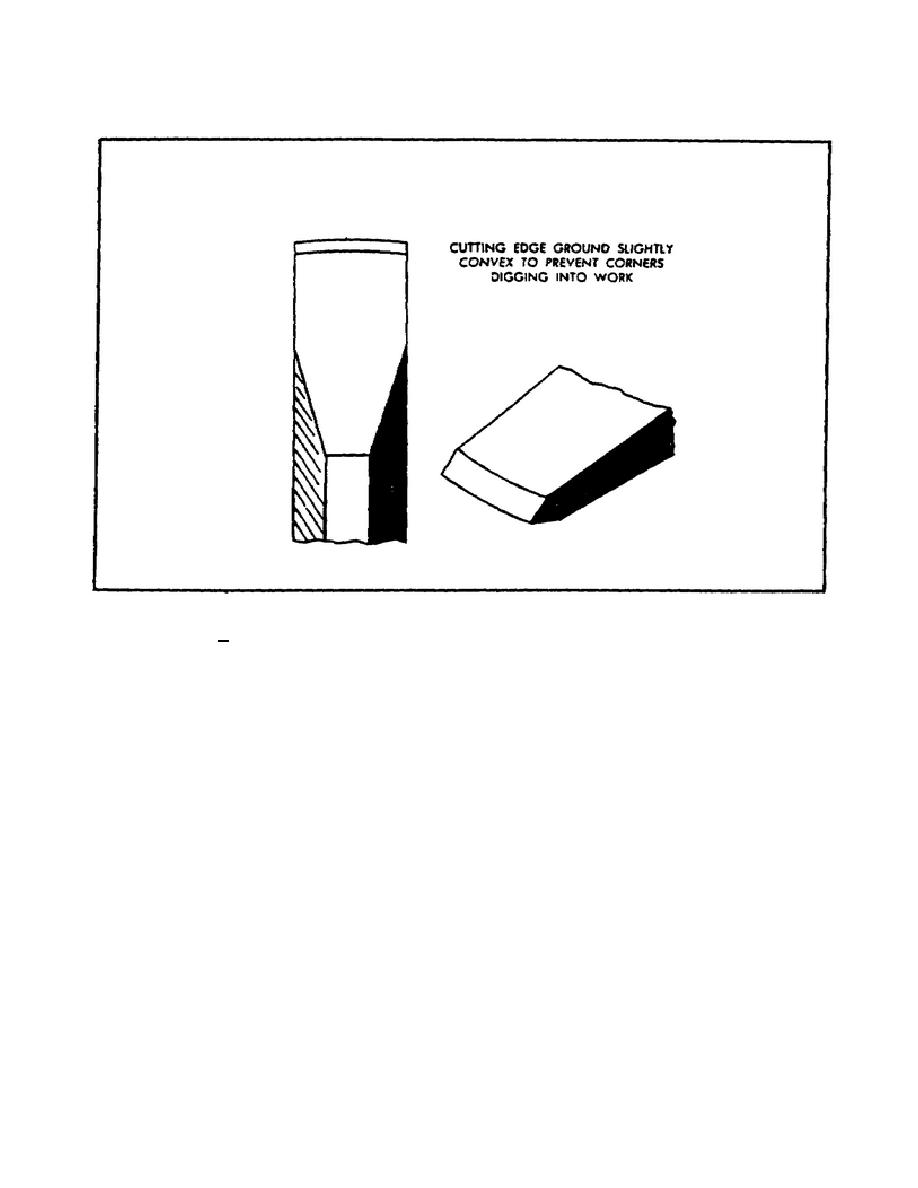

FIGURE 94.

CUTTING EDGE OF MACHINIST'S FLAT OR COLD CHISEL.

7 Turn the chisel over to grind the other bevel. The bevels

should be ground alike in width and should form equal angles with the

centerline of the chisel.

The roundnosed chisels have one bevel, like a

wood chisel.

The standard included angle between the surfaces which form

the cutting edge should be the same, whether these surfaces are both bevels,

or one bevel and the other flat.

In a one bevel chisel, therefore, the

angle that the bevel forms with the centerline of the chisel should be twice

as large as in a chisel having two bevels.

(b) Hardening and Tempering. Machinist's and blacksmith's chisels

often require hardening and tempering.

To harden a chisel, heat it to a

cherry red in a suitable furnace or forge, after removing the wood handle in

case of the blacksmith's chisel. Hold the chisel in the center with a pair

of tongs and dip the cutting end in cold water to a depth of 1 1/4 inches.

Turn the chisel over and dip the chisel head to a depth of 1 inch. Polish

the hardened ends with a file or aluminum oxide abrasive cloth. Watch for

color to return to the ends from the very hot center section. Every time

the cutting end turns purple, dip it. Redip the head every time it turns

blue. When the red disappears from the chisel, dip the whole tool to check

further drawing of temper. The same

121

Previous Page

Previous Page