TM 9-8000

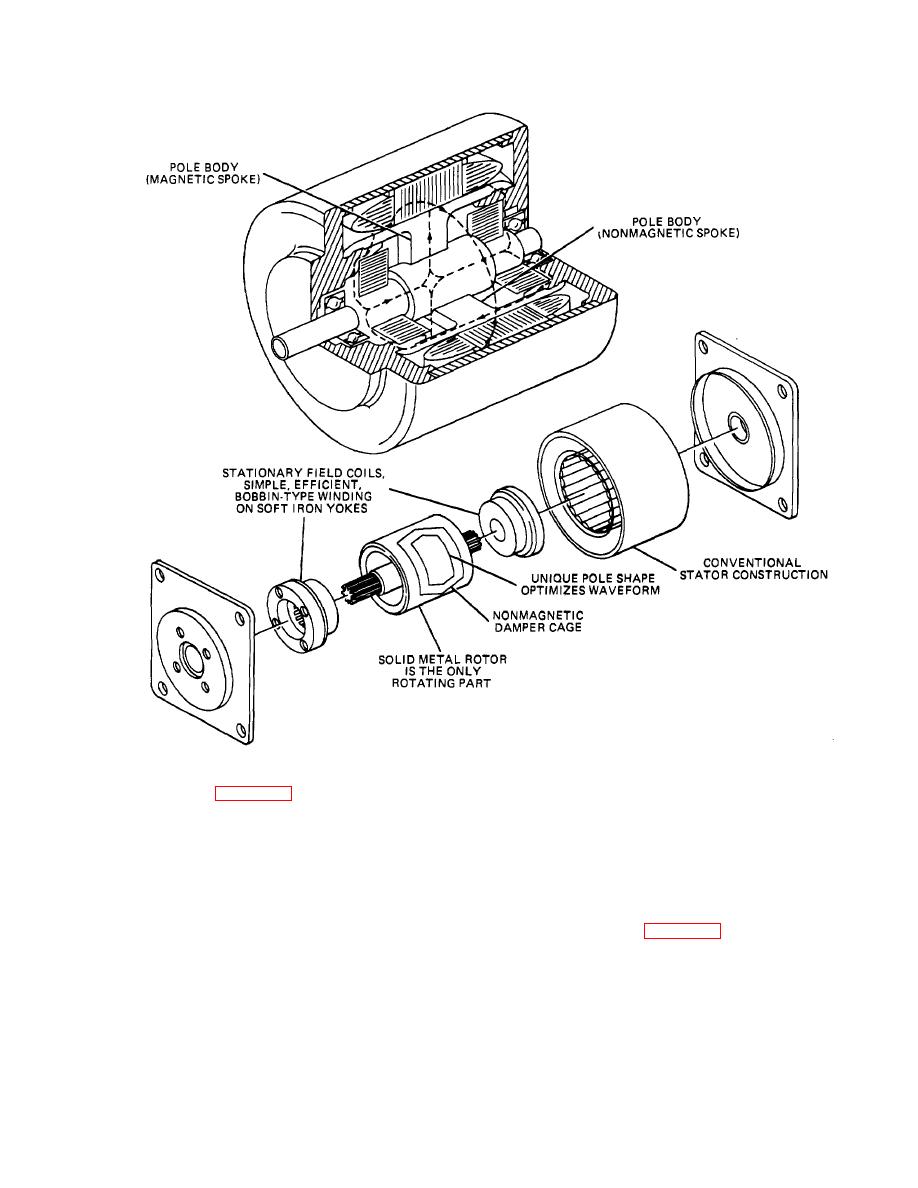

Figure 13-30. Lundell Inductor.

a. Air Cooling (A, Fig. 13-33). In tank-automotive

abrasive particles, water, or other substances to the

generator interior. Furthermore, rotor and stator design

applications, air cooling Is the most common method.

must permit unrestricted passage of air through the

The usual arrangement consists of a fan that forces air

generator. This can be accomplished by designing

through the alternator to cool the rotor, stator, and

passages through the rotor and stator.

However,

rectifier. The major advantage of air cooling Is that the

roughness in the surface of the rotor contributes to

generator and cooling are self-contained, drawing air

windage losses, further affecting unit efficiency.

from the environment.

However, fan power

requirements can become excessive at high speeds

b. Oil Cooling (B, Fig. 13-33). 0il cooling features

because fan designs usually are structured to provide

a transfer of alternator heat into the circulating oil flow,

sufficient cooling at the lowest speed corresponding to

followed by cooling of the hot oil in a heat exchanger.

rated output. Fan power at high speeds then appears as

The oil supply can be part of the driving power system

a severe reduction in generator efficiency. Another

factor is that, unless it is filtered, cooling air can deliver

TA233565

13-29

Previous Page

Previous Page