TM 9-8000

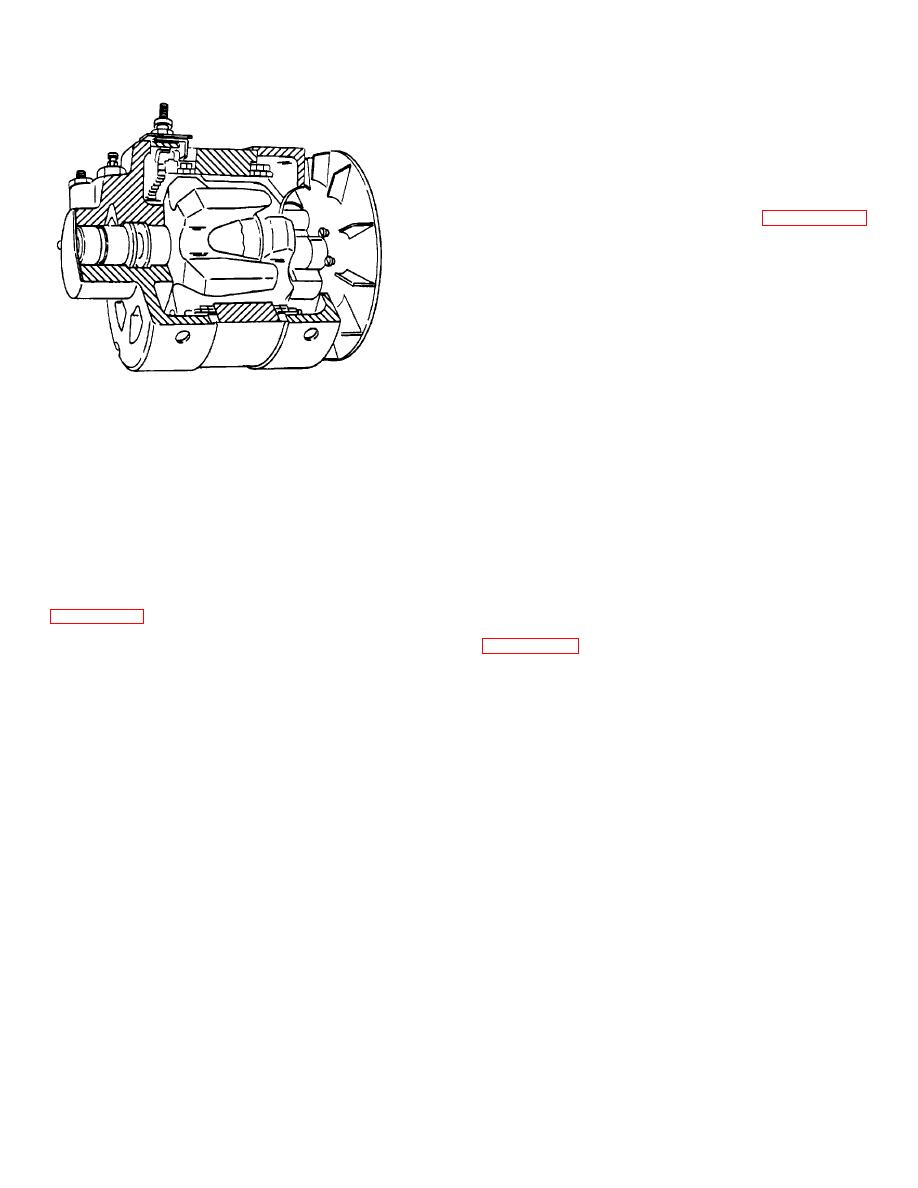

attached to each end of the rotor. The segment varies

the reluctance in the magnetic circuit as it rotates. As a

result, the fixed stator poles experience a variation in

magnetic strength or coupling and produce a resulting

output voltage in the stator coils. In contrast to other

types of generators, the iron does not experience a flux

reversal. Consequently, there is only a 50-percent

utilization of the iron in the stator.

illustrates typical construction of the inductor alternator.

The advantages of an inductor alternator are easier

winding construction for field and stator coils; simplified

cooling; it is brushless; and it has an integral solid rotor

without windings that permits high-speed operation. The

disadvantages of an inductor alternator are that it has

less than 50 percent use of iron, resulting in a heavier

unit and the increased total air gap in the magnetic circuit

requires more excitation.

e. Brushless-Rotating Rectifier. Another means for

eliminating brushes and sliprlngs is found in the rotating

Figure 13-29. Rotor-to-Stator Relationship.

rectifier type of alternator. The machine consists of five

main functional elements. These include a stator-

that the rotor contains no windings. Excitation is induced

mounted exciter field, the exciter armature, a main

in the rotor poles by stationary field coils located at the

rotating field, the main output stator windings, and the

ends of the rotor. This results in the elimination of

output rectifier assembly.

sliprings and rotating windings. Further advantages can

be obtained by casting a nonmagnetic material around

The exciter field induces alternating current in the

the pole fingers, thus producing a smooth rotor with low

rotating armature and the output is rectified and directly

windage losses and high speed capability. An inherent

coupled to the rotating main field, which excites the

design requirement of this stationary field arrangement is

stator-mounted output windings. With this arrangement,

the inclusion of an auxiliary air gap in the magnetic

a small amount of exciter field excitation can be

circuit. This requires greater field current for excitation.

amplified in the exciter stage to supply a high level of

main field current. A diagram of elements is shown in

a variety of advantages to a Lundell inductor. There are

no slipring wear or contamination problems, and the unit

alternator. The advantages of the brushless rotating

is inherently explosion proof. The rotor can be solid and

rectifier are that it is brushless and a low exciter field

permanently balanced. All windings are stationary and

current permits a low-level regulator. However, the

readily accessible for cooling. The low rotor mass

disadvantages of the brushless-rotating rectifier are that

reduces bearing loads and permits rapid acceleration.

a wound rotor limits top speed, multiple windings

The bearing center-to-center distance is minimized by

contribute to complexity and cost, a large number of

the elimination of sliprings, and this, combined with a

heat-producing rotating elements increases cooling

large shaft diameter, permits high-speed operation. The

requirements, and a large magnetic circuit limits

field windings are simple, bobbin-wound coils permitting

response.

short mean turn length. The only disadvantage is that

extra air gaps in the magnetic circuit require increased

13-25. Cooling Generators. The common methods

excitation power.

used for cooling generators use heat transfer by airflow

or oil circulation. Each has its particular application

d. Inductor Alternator. An inductor alternator employs

based on their advantages and disadvantages.

a fixed, non-rotating field coil that induces excitation in

TA233564

the central portion of the rotor as if it were a solenoid.

Each end of the rotor assumes a polarity. A multilobed

segment is

13-28

Previous Page

Previous Page