(g) Rotate the diestock clockwise a few short strokes to start the cut.

Lock ratchet and pump handle up and down several strokes (fig 40).

(h) Reoil die.

(1) Reverse ratchet and stroke frequently to free die of chips.

(j) Thread pipe until threaded end of pipe projects 1/4 to 1/2 inch from

diestock.

(k) After threading, set ratchet for reverse operation and back off die.

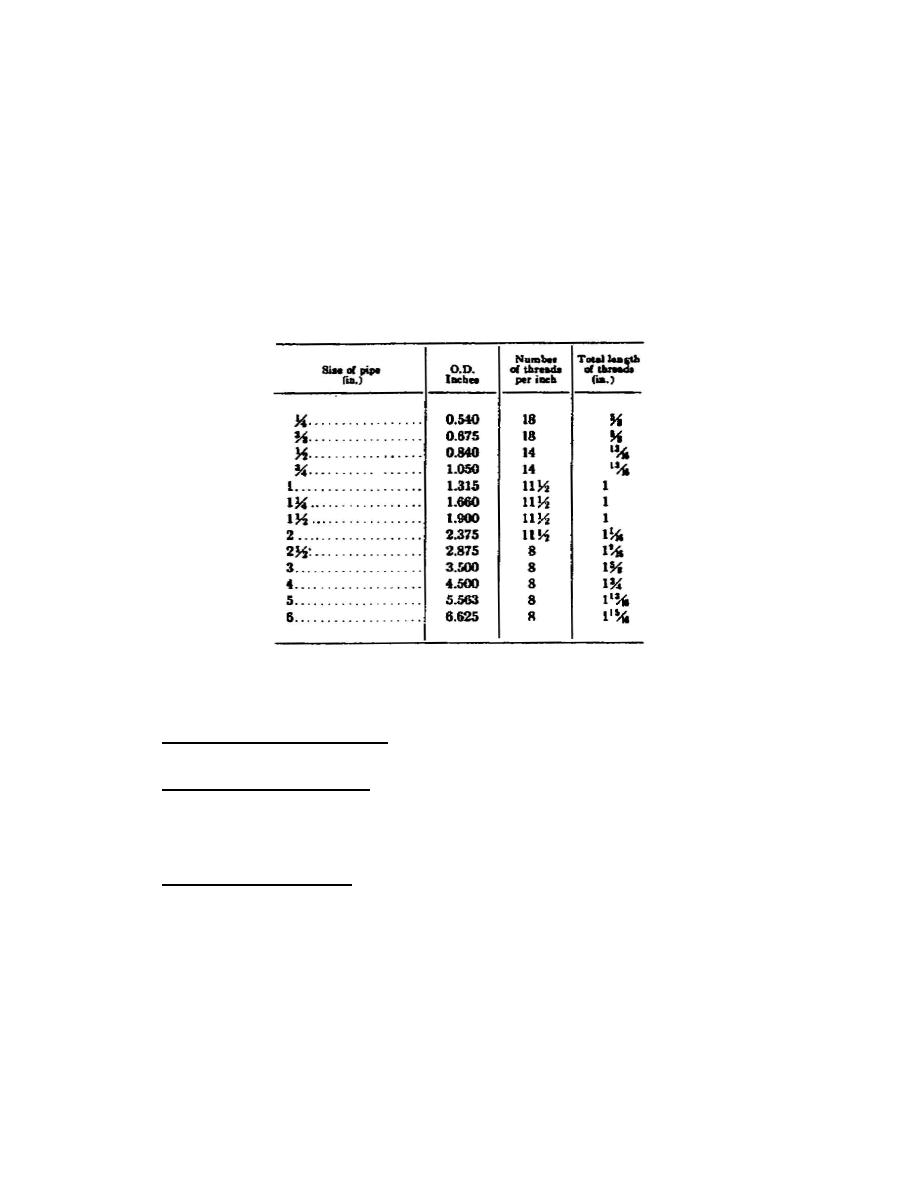

(1) Check for proper length of threaded pipe. For determining the

length of threaded pipe for standard fittings and couplings for various size pipe,

refer to figure 41.

Figure 41.

Pipe thread data for standard pipe.

11.

THREAD CHASERS.

a. Purpose of thread chasers.

Thread chasers are used to rethread damaged

external or internal threads.

b. Types of thread chasers. Thread chasers (fig 42) are threading tools that

have several teeth. These tools are available to chase threaded parts having

standard threads. The internal thread chaser has its cutting teeth located on a

side face. The external thread chaser has its cutting teeth on the end of the

shaft. The handle end of the tool shaft tapers to a point.

c. Use of thread chasers. Select the proper thread chaser for the job. You

must know the number of threads per inch on the work. Simply use a rule to measure

off a distance and count the threads in the measured distance. If screw pitch

gages are available use them to determine the number of threads per inch. Secure

the work securely in a vise or hold it in one hand. Hold the chaser in the other

hand and run it around the threaded section. Hold chaser firmly so that the

cutting teeth are parallel to the threads in the work. The cutting action will

follow the previously cut threads and restore the damaged portion.

85

Previous Page

Previous Page