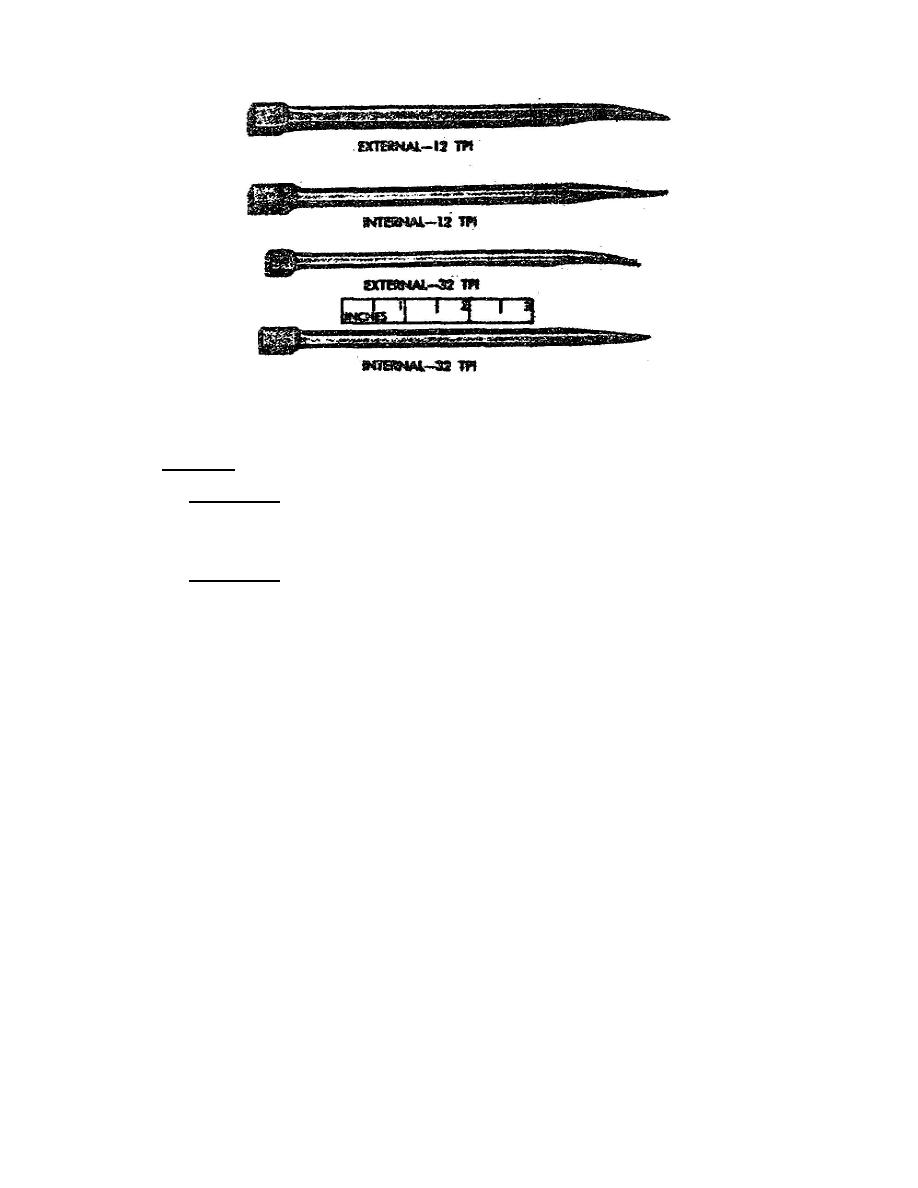

Figure 42.

Thread chasers.

12.

JOINING.

a. Fittings.

(1) Principles. Fittings are generally screwed to one end of the pipe

while it is still in the vise after cutting, reaming, and threading. The assembled

pipe and fittings are then screwed into the proper place on the equipment. The

steps below describe how to make up leakproof joints.

(2) Procedure.

(a) Inspect the female thread on the fitting and, if necessary, clean it

with a stiff brush.

(b) Repeat the same procedure for the male thread on the pipe.

(c) Coat the male thread evenly with pipe joint compound.

Do not put

any compound on the female thread.

(d) Screw the fitting on the pipe, making sure that the fitting turns

easily for the length of about three threads.

(e) Using a wrench, tighten the fitting on the pipe until the joint is

tight. Figure 43 shows three common wrenches which were covered in lesson 1. The

stillson wrench {1, fig 43) is used for ordinary work; the strap wrench (2, fig 29)

for polished or plated pipe; and the chain wrench or chain tongs (3, fig 43) for

pipe 3 inches or larger. Use the right size wrench for the size of pipe and never

use a length of pipe as an extension handle for added leverage. Use a second

wrench to keep an already installed pipe or fitting from turning. If a pipe has

been threaded to the correct length, two or three threads will show beyond the face

of the fitting.

(f) Wipe off excess joint compound and paint the exposed threads with an

acid-resistant paint.

86

Previous Page

Previous Page