(a) Diameter and pitch of tapped hole. The coarser the pitch, the

larger is the thread depth if a full thread were cut. Try a drill giving 75

percent thread depth first. If tap breakage results, reduce the thread depth

gradually by using larger drills until satisfactory performance is obtained.

Note.

-

A nut with only 50 percent thread depth will break the bolt before it

strips the thread.

American Standard screw threads are standardized in two series: coarse and fine.

As a tap size becomes smaller, the percentage of double thread depth in relation to

basic major diameter of the screw generally becomes larger.

% Double thread depth

Basic major diameter

Coarse

Fine

1.0 inch

16

9

0.750 inch

17

11

0.500 inch

20

13

0.375 inch

22

14

0.250 inch

26

19

No 5 machine screw

26

24

(b) Nature of material being tapped. Soft metals such as copper,

aluminum, monel metal, nickel silver, and the low melting point alloys have a

tendency to flow toward the root of the minor diameter of the tap while being

tapped. The minor diameter of tapped holes in such material will be smaller after

tapping. Take this into consideration when selecting the tap drill of sufficient

size. Use the smallest thread depth possible on materials that are very tough or

of high hardness. This is accomplished by using the largest drill possible, which

nevertheless will be smaller than the one used for softer materials under similar

circumstances.

(c) Depth of tapped hole. Larger tap drills giving 50 percent thread

depth may be used when holes are deeper than 1-1/2 times the tap diameter. Punched

holes often cause binding and tap breakage, especially in thin sheet metal, which

creates an "oilcan" effect. When the hole is punched, the metal is flared out. As

the tap is reversed after threading, it draws in this flare and binds. Consider

this when selecting punch size. The larger the punched hole, the less tendency for

the tap to bind. Holes formed in castings and forgings should be checked for 75

percent depth and reamed to size, if necessary, before tapping.

(2) Tapping a hole.

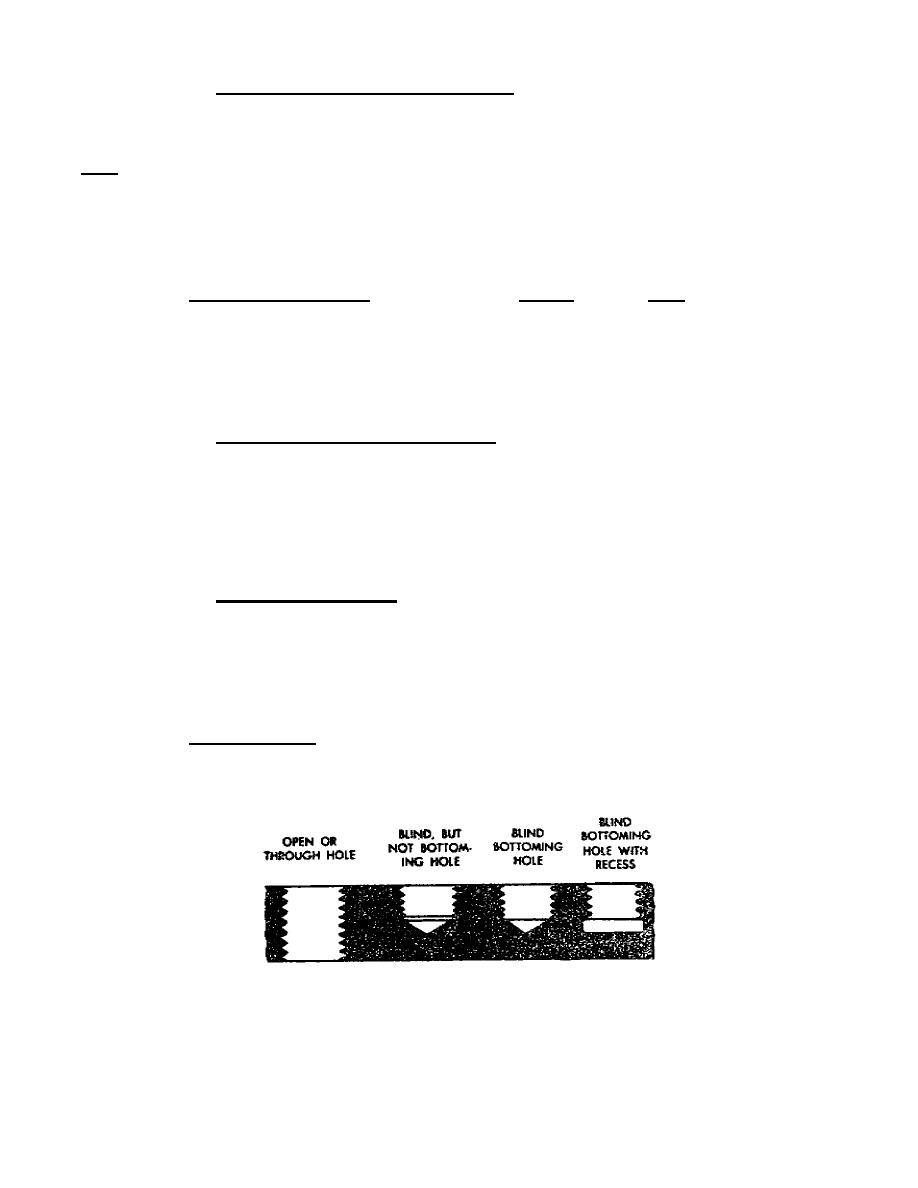

(a) After the proper size and type hole (fig 36) is drilled and cleaned,

secure the tap in a tap wrench.

Figure 36.

Types of drilled holes.

81

Previous Page

Previous Page