(a) Spring caliper.

1. The spring caliper is available in sizes from 2 to 8 inches. The

friction of the adjusting nut and screw works against the tension of the spring

which holds the legs in any set position. This type of inside caliper is known as

the toolmaker's spring caliper.

2. Thread spring calipers are used to measure diameter and distances

in tapped holes. The ends of the legs of thread calipers are shaped to a fine

point so that exact contact may be made between threads.

(b) Firm joint caliper. The firm joint type is available in a number of

sizes from 3 to 24 inches. This type of caliper is equipped with a nut and stud

that provide sufficient friction to hold the legs in any set position. Some of

this type caliper are equipped with an adjusting screw for fine adjustments.

(c) Transfer firm joint caliper. Inside transfer firm joint calipers

are shaped for inside measurements and are used for measuring recesses where the

setting cannot be transferred to a scale directly because the legs must be

collapsed to remove them from the work.

(3) Use of calipers.

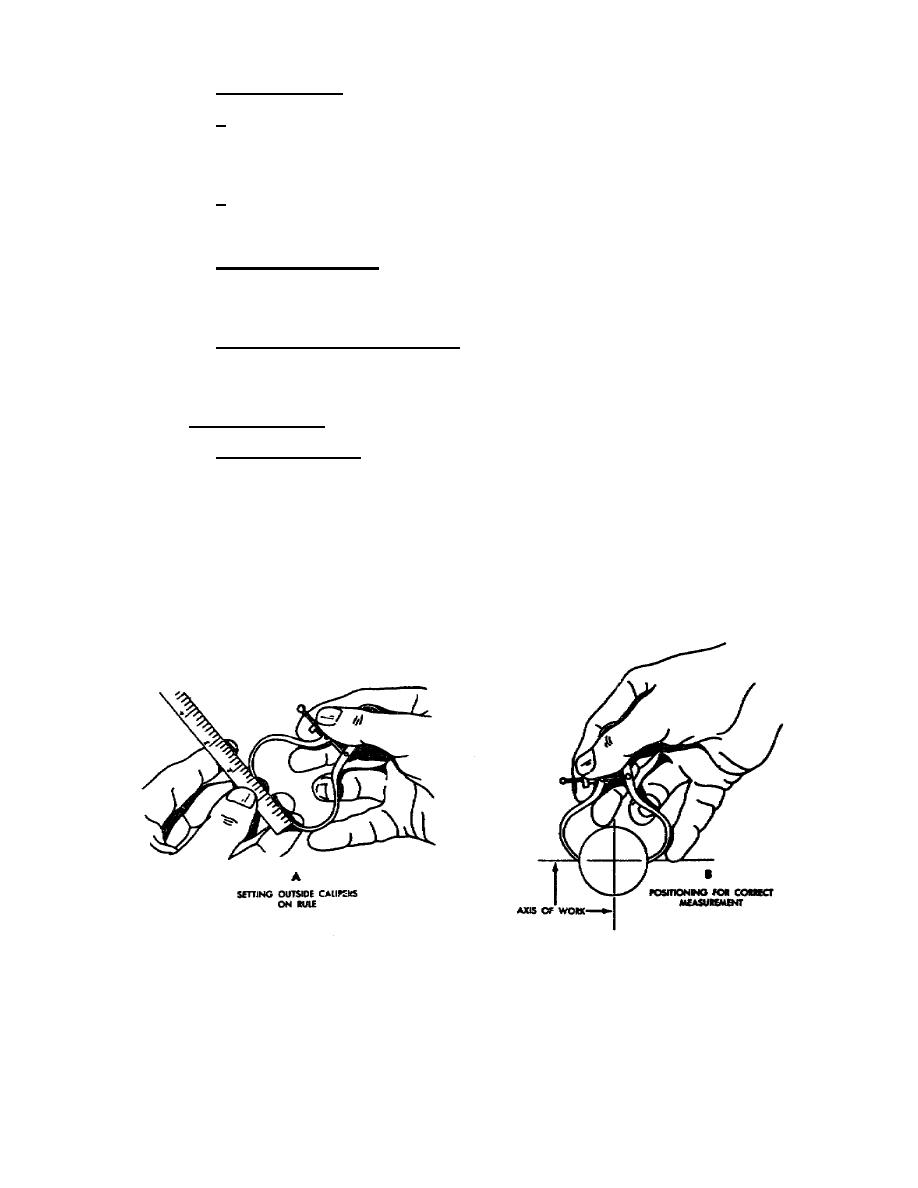

(a) Outside calipers. A caliper is usually used in either of two ways.

Either the caliper is set to the dimension of the work and the dimension

transferred to a scale, or the caliper is set on a scale and the work machined

until it checks with the dimension set up on the caliper. To adjust an outside

caliper to a scale dimension, one leg of the caliper should be held firmly against

one end of the scale and the other leg adjusted to the desired dimension (A, fig

51). To adjust the outside caliper to the work, open the legs wider than the work

and then bring them down to the work. A sense of feel must be acquired to use

calipers properly. This comes through practice and care in using the tool to

eliminate the possibility of error. Always position the caliper properly on the

axis of the work (B, fig 51).

Figure 51.

Using outside calipers.

43

Previous Page

Previous Page