(2) Straight hole reamers. A hand reamer is turned by means of a tap

wrench that is tightened on the square end of the reamer shank. Secure the work in

a vise so that the hole to be reamed is perpendicular to the top of the vise jaws.

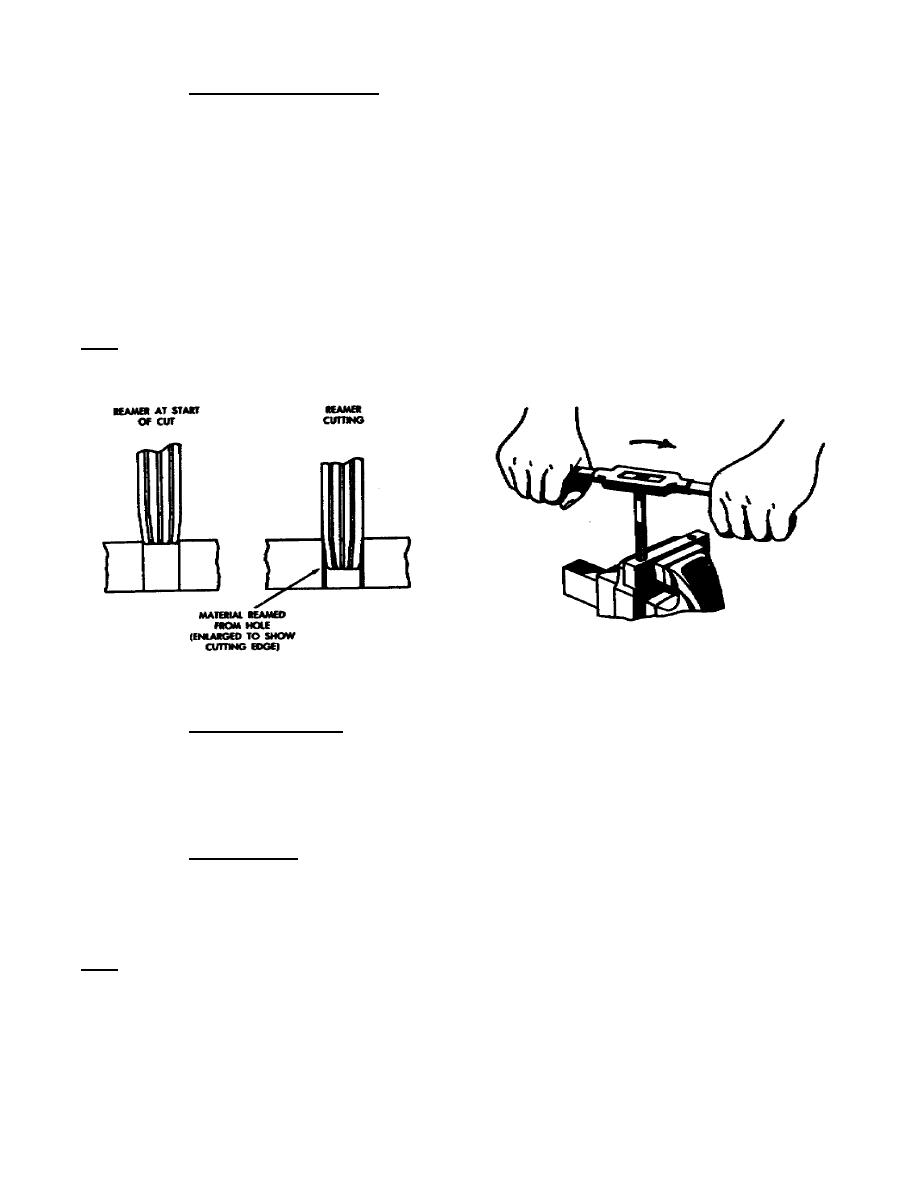

Position the reamer at the top of the hole (fig 26). Straight hole reamers have a

slight taper at the end so that they will fit into the hole easily. Turn the

wrench clockwise very slowly until the reamer is centered in the hole (fig 27).

CAUTION:

Do not turn the wrench counterclockwise at any time. To do so will

cause the tool to become dull, fail to cut, and become useless.

After centering the reamer, turn the wrench clockwise with a steady firm pressure

until the reamer has been turned all the way through the hole. When reaming steel.

use cutting oil or machine oil to lubricate the tool. When reaming soft iron, do

not lubricate the tool. To remove reamer from hole, turn wrench clockwise and

raise reamer simultaneously.

Note.

-

Turning the wrench too fast or too slowly will cause the reamer to

chatter, producing an unevenly reamed hole.

Figure 26.

Reaming operation.

Figure 27.

Use of tap wrench with reamer.

(3) Taper pin reamers. Before using a taper pin reamer be certain that the

hole is the right size, generally just large enough to allow about 1/2 inch of the

reamer's length to go into it. The drill used to make the hole must be the largest

possible size that will allow the reamer to clean up the hole along its entire

depth. Keep the reamer as straight as possible and ream hole as discussed above.

To prevent damage to the walls of the hole, remove the reamer frequently and brush

away the metal chips that stick to the flutes.

(4) Pipe reamers. Before using a pipe reamer (fig 28), inspect the flutes

to see if they are sharp and even and free from nicks or burs. Insert the point of

the reamer into the pipe and push firmly. Rotate the handle of the reamer

clockwise in short even strokes until the burs inside the cut piece of pipe are

completely removed. Remove the reamer from the pipe by rotating it clockwise and

removing it simultaneously.

Note.

-

The pipe must be secured in a pipe vise during this bur removing

operation.

74

Previous Page

Previous Page