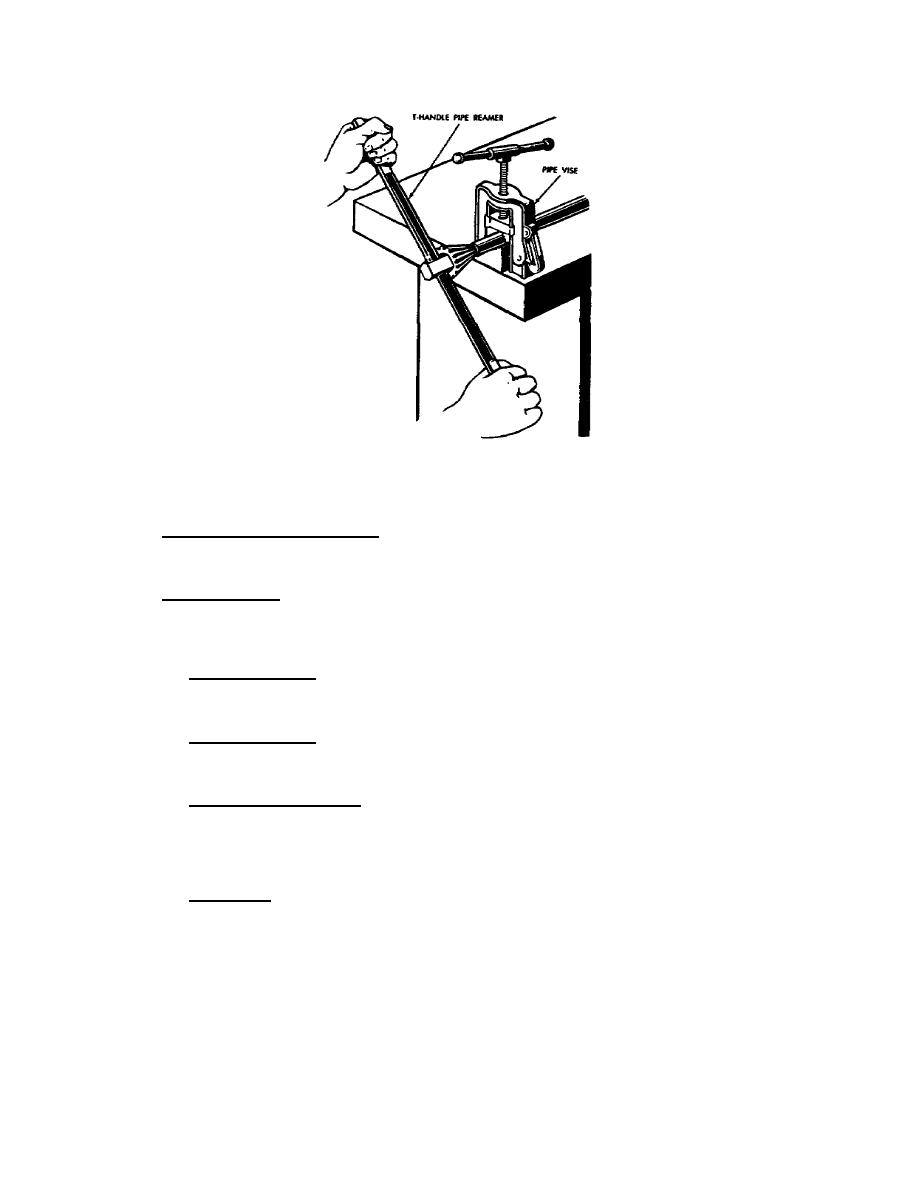

Figure 28.

Removing bur from cut pipe.

10.

THREADING.

a. Purpose of taps and dies. Taps and dies are used to cut threads in metal,

plastics, or hard rubber. The taps are used for cutting internal threads and the

dies are used to cut external threads.

b. Types of taps. There are several types of taps issued by the supply

system. However, the most common are the taper, plug, bottoming, and pipe taps

(fig 29). Special purpose taps (fig 30) such as mud or washout taps, boiler taps,

and staybolt taps are also discussed in this paragraph.

(1) Taper hand tap. The taper or starting hand tap (fig 29) has a chamfer

length of 8 to 10 threads. These taps are used when starting the tapping operation

and tapping coarse threads in through holes especially in harder metals.

(2) Plug hand taps. Plug hand taps (fig 29) are designed for use after the

taper tap and in through holes when tapping softer metals or fine-pitch threads.

They have a chamfered length of 3 to 5 threads. These taps. are the most popular.

(3) Bottoming hand taps. Bottoming hand taps (fig 29) are used for

threading the bottom of a blind hole. They have a very short chamfer length of

only 1 to 1-1/2 threads for this purpose. This tap is always used after the plug

tap has already been used and for hard materials. Both the taper hand and plug

hand taps should precede the use of the bottoming hand tap.

(4) Pipe taps. A taper pipe tap (fig 29) is used for pipe fittings and on

other places where extremely tight fits are necessary. The tap diameter, from end

to end of threaded portion, increases at the rate of 3/4 inch per foot. All

threads on this tap cut as compared to the straight taps where only the

nonchamfered portion does the cutting.

75

Previous Page

Previous Page