(4) Chromium and stainless steels. These and other allow steels that

heretofore could only be cut by a melting action, rather than by rapid oxidation,

can now be cut by the introduction of iron powder or a special nonmetallic powdered

flux into the cutting-oxygen stream. The iron powder oxidizes quickly and

liberates a large quantity of heat. This high heat, in turn, melts the refractory

oxides which normally protect the steel from the action of oxygen. These molten

oxides are flushed from the cutting face and the cutting oxygen is enabled to, act

upon the iron remaining in the steel. The nonmetallic flux, introduced into the

cutting-oxygen stream, combines chemically with the refractory oxides producing a

slag of a lower melting point that is washed or eroded out of the cut; thus,

exposing the steel to the action of the cutting oxygen.

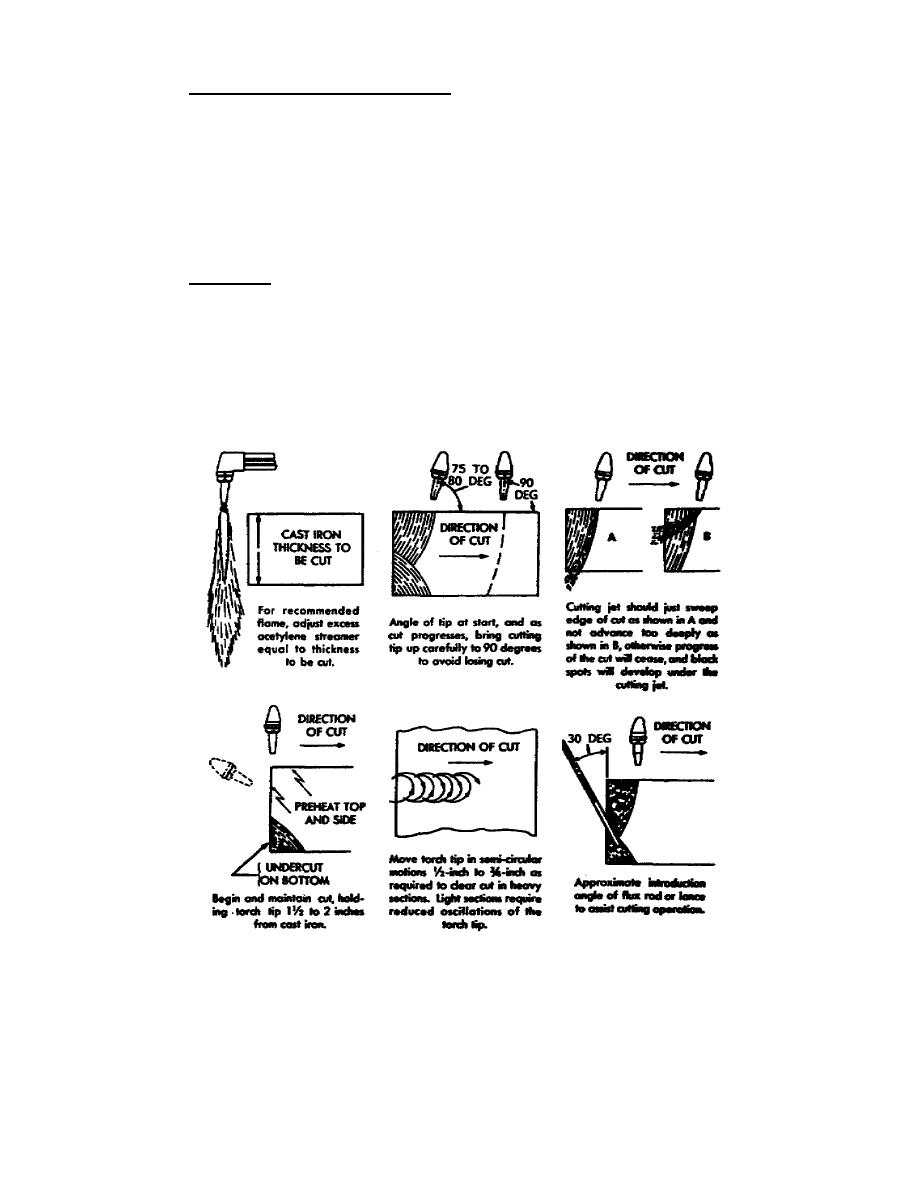

(5) Cast iron. Cast iron melts at a temperature lower than its oxide;

therefore, in the cutting operation, the iron tends to melt rather than to oxidize.

For this reason, the oxygen jet is used to wash out and erode the molten metal when

cast iron is being cut. To make this action effective, the cast iron must be

preheated to a high temperature and much heat must be liberated deep in the cut.

This is affected by adjusting the preheating flame so that there is an excess of

acetylene. The length of the acetylene streamer and the procedure for advancing

the arc are shown in figure 17. The use of mild iron flux to maintain a high

temperature in the recesses of the cut is also effective.

Figure 17.

Procedure for oxyacetylene cutting of cast iron.

128

Previous Page

Previous Page