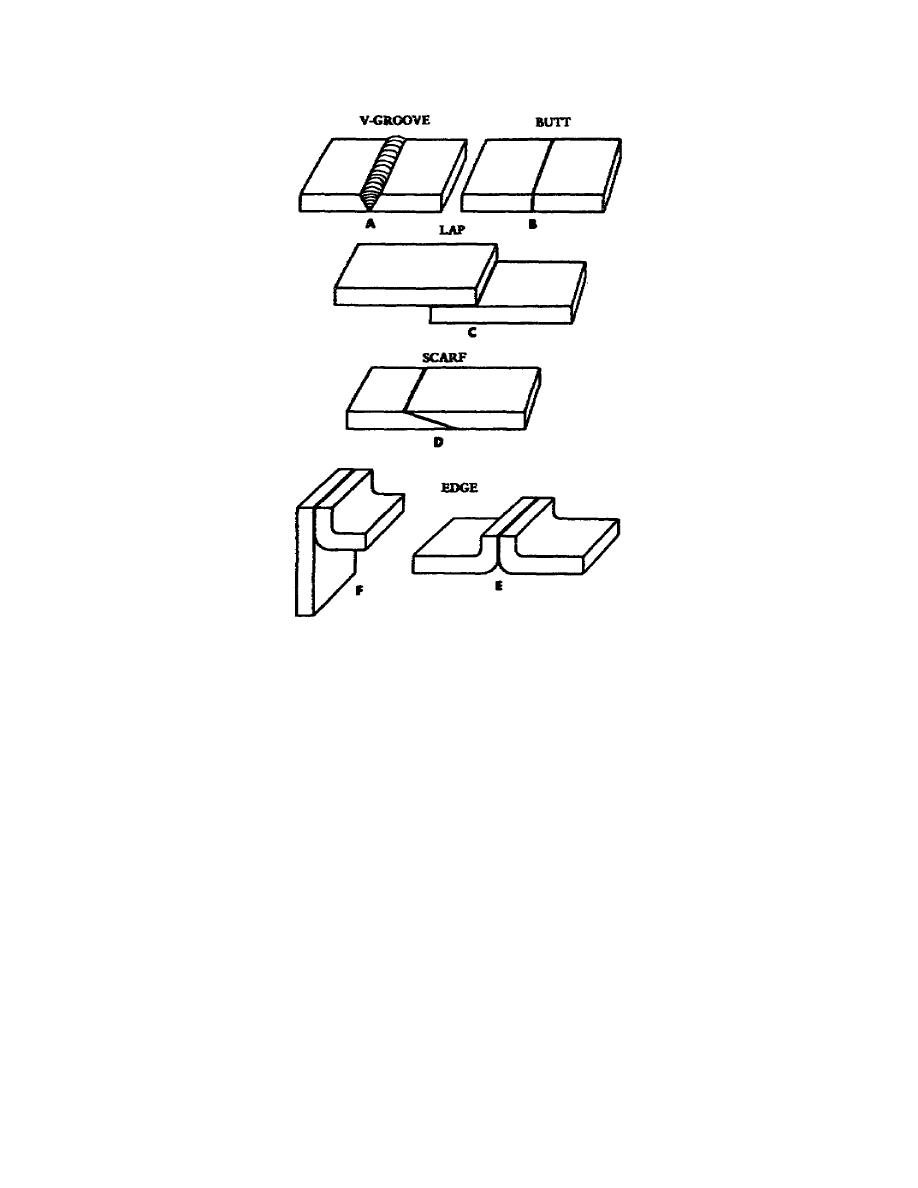

Figure 18.

Joint designs.

c. When brazing or welding material one-sixteenth of an inch or less in

thickness, it is impractical to bevel the joint edges since this would add very

little to the bond area. A square-faced butt joint with an increased bond area,

obtained by depositing filler material on a wide faced area, is more suitable.

d. In order to obtain the maximum bond strength, the joint surfaces must be

bright and free from oil, rust, paint, or other foreign matter. The edges to be

joined must be cleaned on both the bottom and upper surface.

24.

APPLICATION OF FILLER ROD.

a. If the base metal is overheated, the filler metal will become overheated

and this will result in a porous deposit. Overheating will also cause the filler

metal to collect in little globules, which are driven away by the force of the

flame.

b. If the temperature of the base metal is too low, the filler metal does not

flow ahead by itself.

c. The best results are obtained by using a slightly oxidizing flame, heating

to the correct temperature, and then applying small quantities of the filler metal

only as required.

132

Previous Page

Previous Page