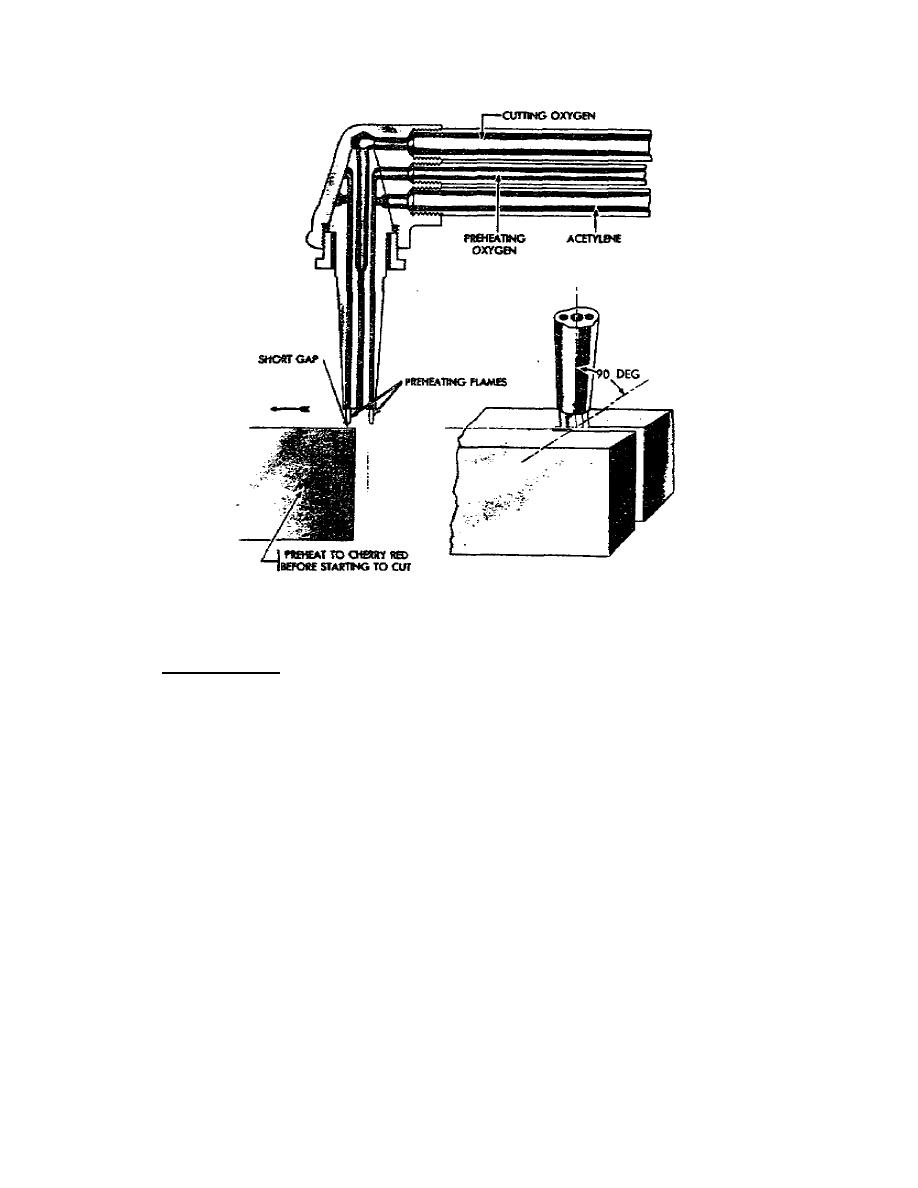

Figure 13.

Starting a cut and cutting with a cutting torch.

19.

EQUIPMENT.

a. Cutting torch.

(l) The cutting torch (fig 14) is an apparatus for mixing oxygen and

acetylene in definite proportions, burning the mixture in preheating flames that

are allowed to impinge upon the work, and directing a jet of high-pressure oxygen

to sever the ferrous material along the line of cut. In appearance, the hand-

cutting torch is somewhat similar to a welding torch, but it differs in its

construction and method of control. It consists principally of a handle,

connecting tubes, and head. The handle is equipped, at the rear end, with oxygen

and acetylene hose connections. A needle valve in the acetylene inlet connection

controls the supply. The oxygen furnished to the preheating flames is regulated by

a preheat valve on the side of the handle. A high-pressure oxygen valve, operated

by a trigger or lever, controls the cutting oxygen.

(2) In some cutting torches, the preheating oxygen and acetylene do not mix

until they are in the cutting tip. Such torches have three gas tubes: one for

high-pressure oxygen (top), one for preheating oxygen (middle), and one for

acetylene (bottom). In other cutting torches, the preheating oxygen and acetylene

premix in the torch body in a common mixing chamber. Such torches have only two

gas tubes: one for high-pressure oxygen (top) and one for the mixture of gases

(bottom).

123

Previous Page

Previous Page