WELDING OPERATIONS I - OD1651 - LESSON 1/TASK 1

joint. Excessive current will create a very fluid puddle, which

will be difficult to control.

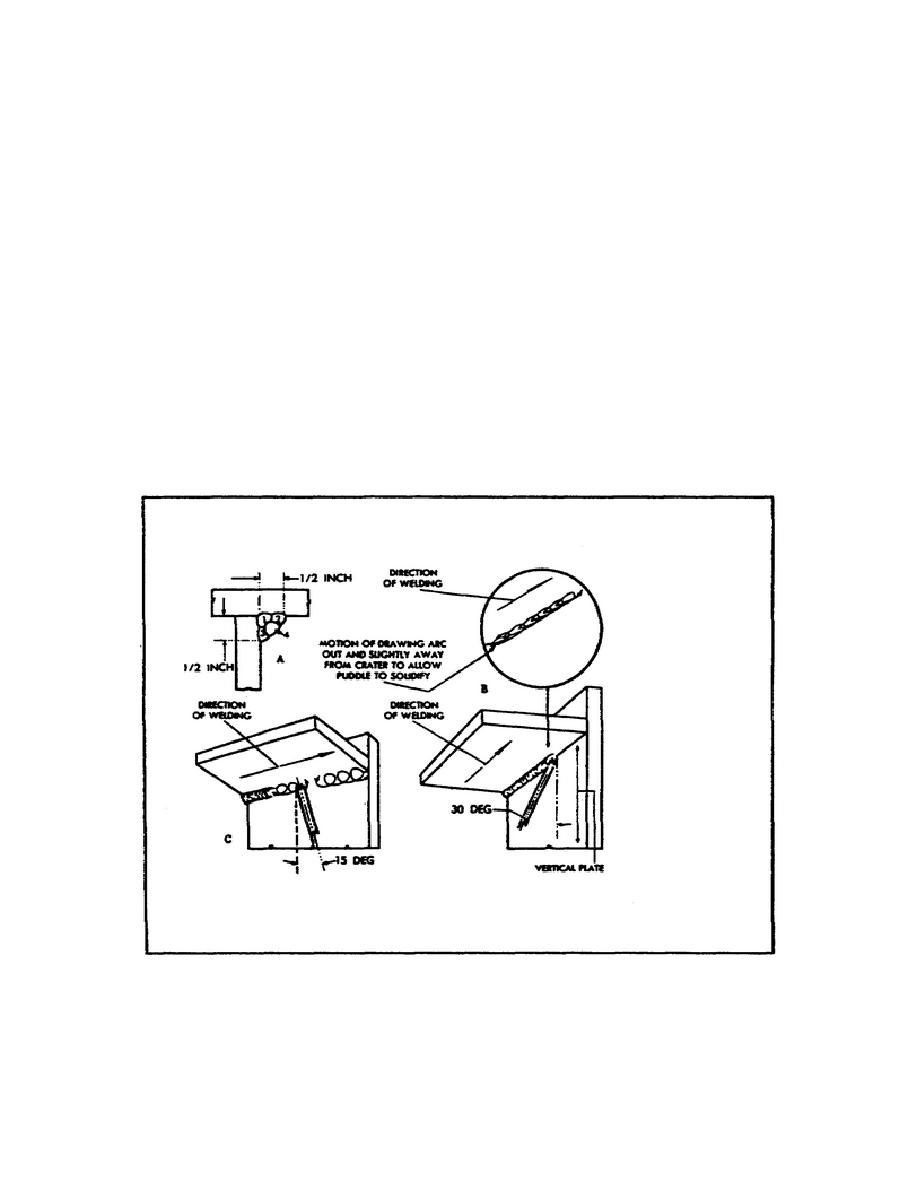

(3) Fillet Welds (figure 24).

(a) In making fillet welds in either tee or lap joints in the

overhead position, a short arc should be held and there should be

no weaving of the electrode.

The order in which the beads are

deposited is shown in figure 24, view A. The electrode should be

held approximately 30 degrees to the vertical plate and moved

uniformly in the direction of the welding as shown in figure 24,

view B.

The arc motion should be controlled to secure good

penetration to the root of the weld and good fusion with the

sidewalls of the vertical and horizontal plates.

If the molten

metal becomes too fluid and tends to sag, the electrode should be

whipped away quickly from the crater and ahead of the weld so as

to lengthen the arc and allow the metal to solidify.

The

electrode should then be returned immediately to the crater and

the welding continued.

FIGURE 24.

OVERHEAD POSITION

FILLET WELDING.

53

Previous Page

Previous Page