METAL BODY REPAIR - OD1653 - LESSON 2/TASK 3

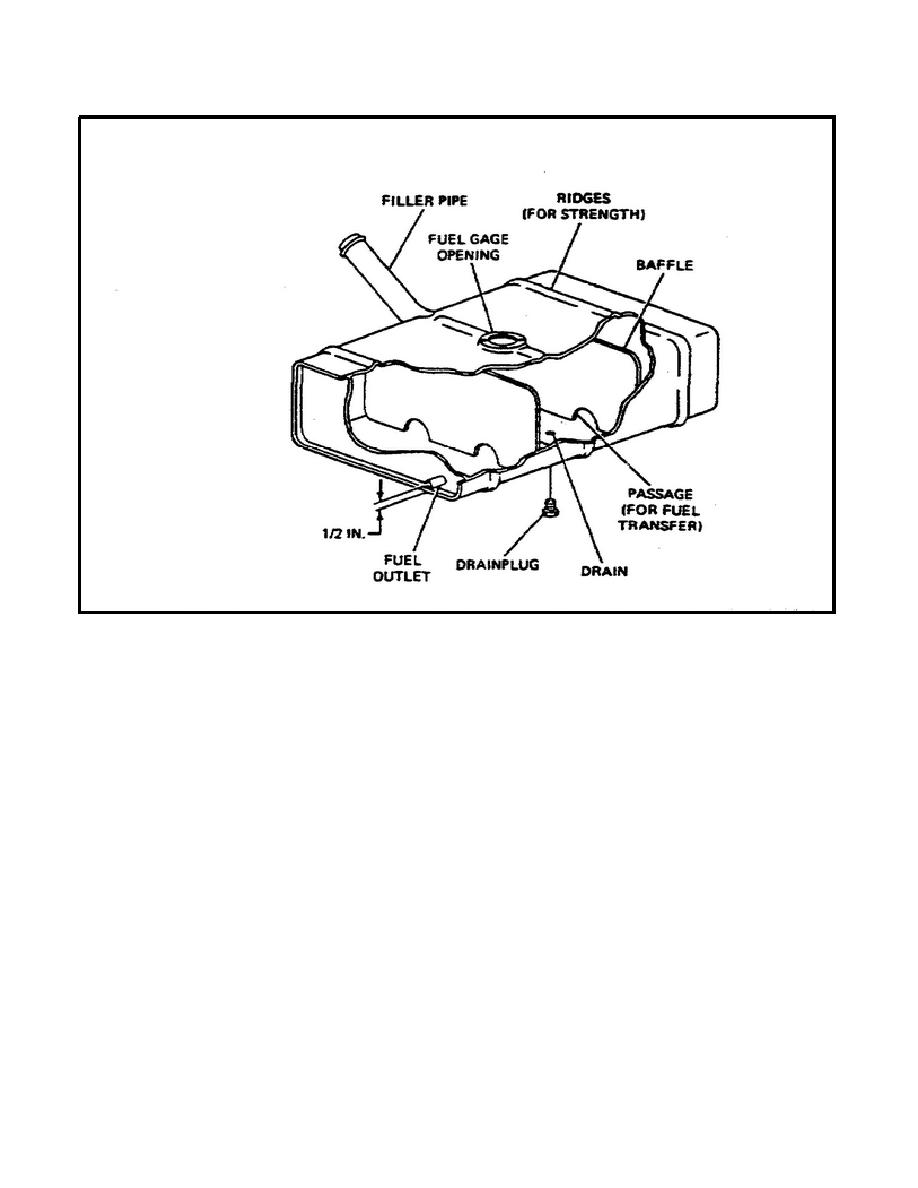

FIGURE 37.

TYPICAL FUEL TANK CONSTRUCTION.

fuel tank used in the Army are wheeled vehicle tanks (terneplate),

fiberglass fuel tanks, cell or bladder-type tanks, and fuel compartments,

which are part of tracked vehicles.

Terneplate is thin gage, low-carbon

steel which is coated on both sides with lead. During its manufacture, the

steel is run through an acid bath and then through a hot-lead dip. The lead

coating adheres to the metal, giving it a tinned coat.

This tinned coat

prevents rust from forming on the inside of the tank, and also makes repairs

easier.

Regardless of their shape and size, all fuel tanks must be designed to

prevent static electricity and excessive splashing. Baffle plates are used

for this purpose. Figure 38 (on the following page) shows the inside of a

fuel tank used on a 2 1/2 ton Army vehicle. Baffle plates are secured to

the top, bottom, and sides of the tank by spot welding or soft soldering.

Newer type vehicles being issued to the Army have fuel tank baffle plates

spot welded to prevent then from breaking loose.

88

Previous Page

Previous Page