WELDING OPERATIONS I - OD1651 - LESSON 1/TASK 2

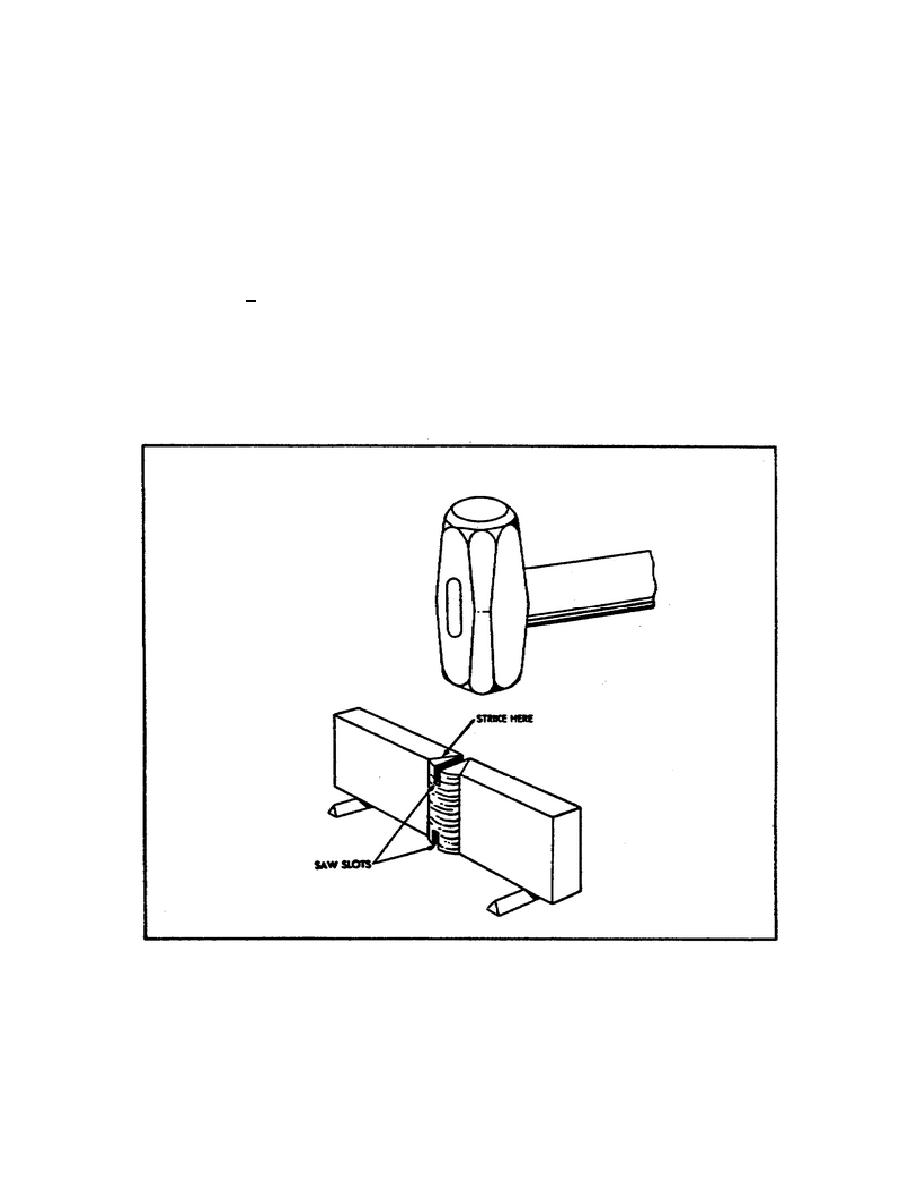

oxyacetylene torch. Each end of the weld at the joint is slotted

with a hacksaw or band saw as shown in figure 47. The specimen

is then bridged across two steel blocks, and struck with a heavy

hammer until the section of the weld between the slots fractures.

The metal thus exposed should be completely fused and free from

slag inclusions. The size of any gas pocket must not be greater

than 1/16 inch at its widest point. The number of gas pockets or

pores should not exceed six per square inch.

b Another break test method is used to determine the

soundness of fillet welds.

This is known as the fillet weld

break test. This test is performed by applying force on the apex

of the V shaped specimen with a hydraulic press or by striking it

with a hammer until the fillet weld ruptures.

The surfaces of

the fracture are then examined for the same defects mentioned in

the preceding paragraph.

FIGURE 47.

NICK BREAK TEST.

98

Previous Page

Previous Page