WELDING OPERATIONS I - OD1651 - LESSON 1/TASK 2

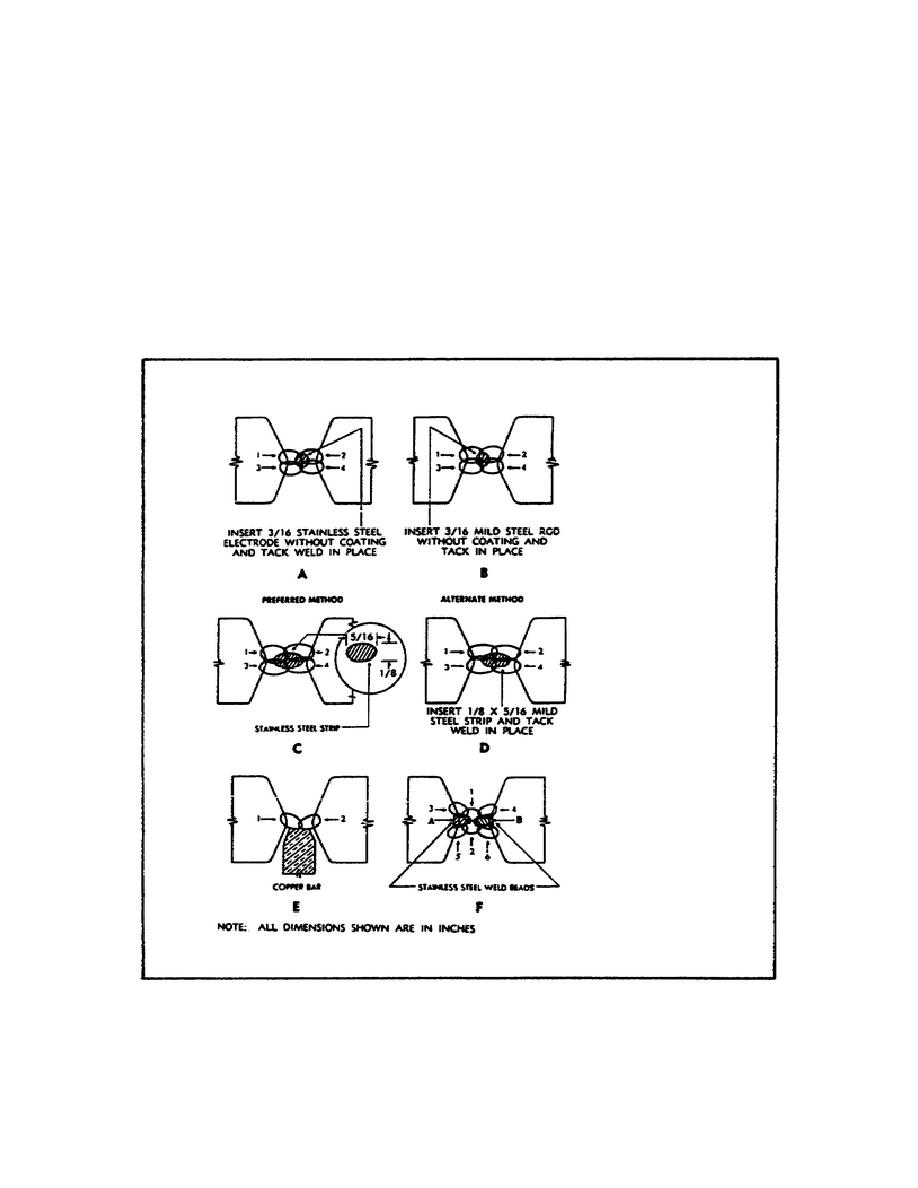

bead welding are shown on figure 28. For narrow root openings, a

3/16 inch stainless steel electrode without coating can be tack

welded in place as shown in figure 28, view A.

Welding bead

numbers 1 through 4 are then deposited sequentially. To ensure a

sound weld, remove all slag and oxides from the joint before

depositing beads 3 and 4. If a mild steel rod or strip, as shown

in figure 28, view B, the back side of the backing rod or strip

should be chipped out after beads 1 and 2 are deposited to

minimize dilution in beads 3 and 4. The use of a stainless steel

strip as a backing for root beads in a wide root opening is shown

as view C of figure 28. An alternate

FIGURE 28.

ROOT BEAD WELD.

71

Previous Page

Previous Page