MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 2

(8)

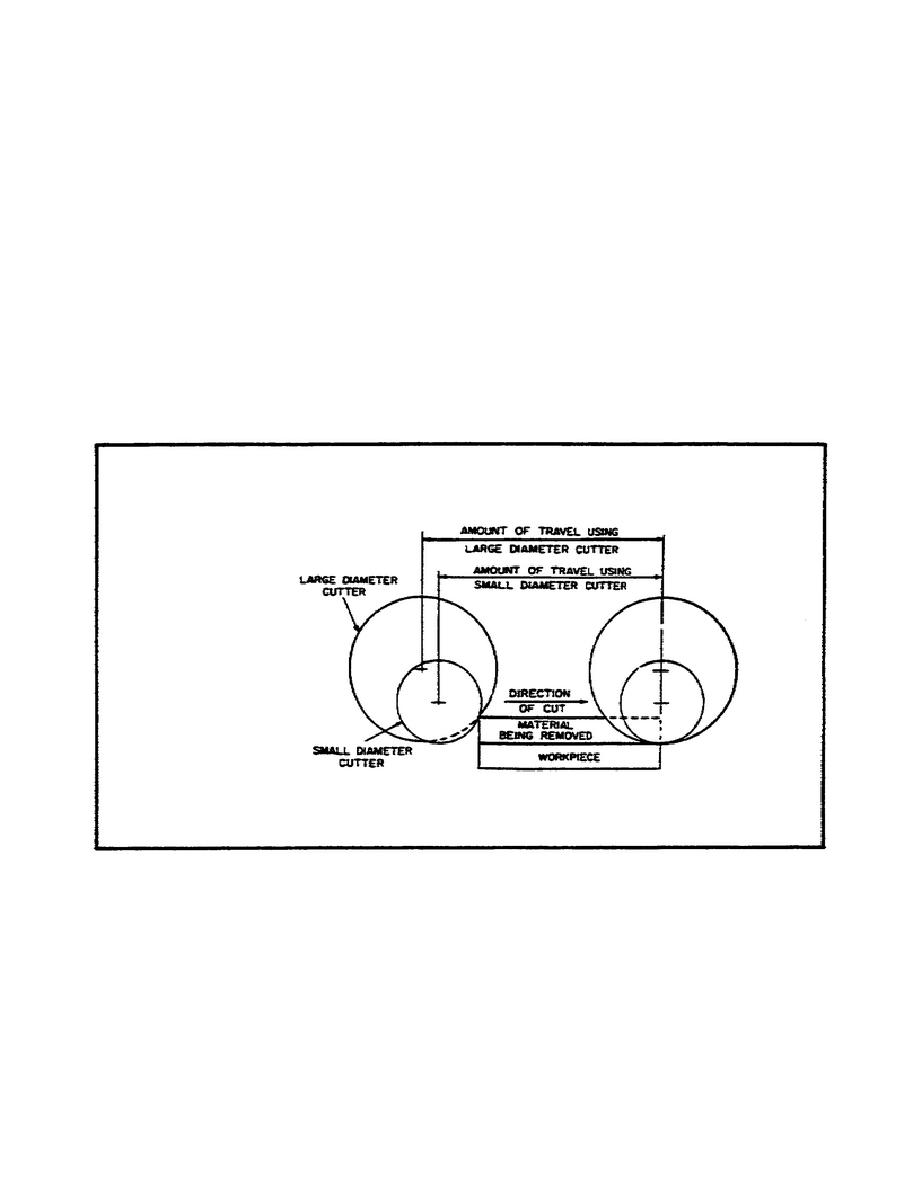

Size of The Milling Cutter.

In selecting a milling cutter for a

particular job, it should be remembered that a small diameter cutter will

pass over a surface in a shorter time than a large diameter cutter fed at

the same speed. This fact is illustrated in figure 33.

d.

Care and Maintenance of Milling Cutters. The life of a milling cutter

can be greatly prolonged by intelligent use and proper storage.

General

rules for the care and maintenance of milling cutters are given below:

(1)

New cutters received from stock are usually wrapped in oilpaper which

should not be removed until the cutter is to be used.

(2)

Care should be taken to operate the machine at the proper speed for

the cutter that is being used; excessive speed will cause the cutter to wear

rapidly from overheating.

FIGURE 33.

EFFECT OF MILLING CUTTER DIAMETER ON WORKPIECE TRAVEL.

(3)

Whenever practicable, the proper cutting oil should be used on the

cutter and the workpiece during the operation, since lubrication helps

prevent overheating and consequent cutter wear.

(4)

Cutters should be kept sharp, because dull cutters require more power

to drive them and this

68

Previous Page

Previous Page