MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 1

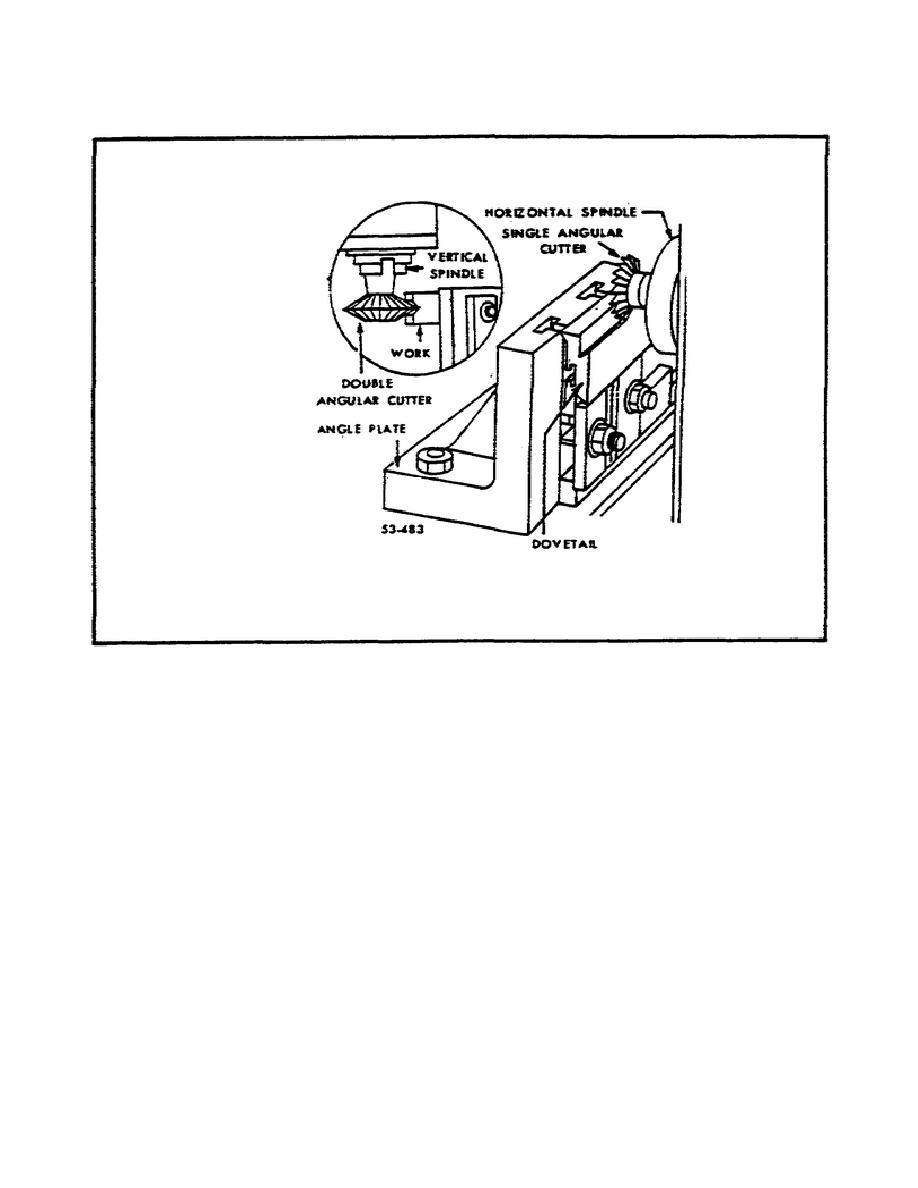

FIGURE 15.

ANGULAR MILLING.

(2)

Operation. Face milling cutters, end milling cutters (figure 16 on

the following page), and side milling cutters are used for face milling

operations.

The size and nature of the workpiece determines the type and

size of the cutter required.

(a)

In face milling, the teeth on the periphery of the cutter do

practically all of the cutting.

However, when the cutter is properly

ground, the face teeth actually remove a small amount of stock which is left

as a result of the springing of the workpiece or cutter, thereby producing a

finer finish.

(b)

It is important in face milling to have the cutter securely mounted

and to see that all end play or sloppiness in the machine spindle is

eliminated.

(c)

When face milling, the workpiece may be clamped to the table or

angle plate, or supported in a vise, fixture, or jig.

(d)

Large surfaces are

generally face milled

on

a vertical

milling

machine with the workpiece

38

Previous Page

Previous Page