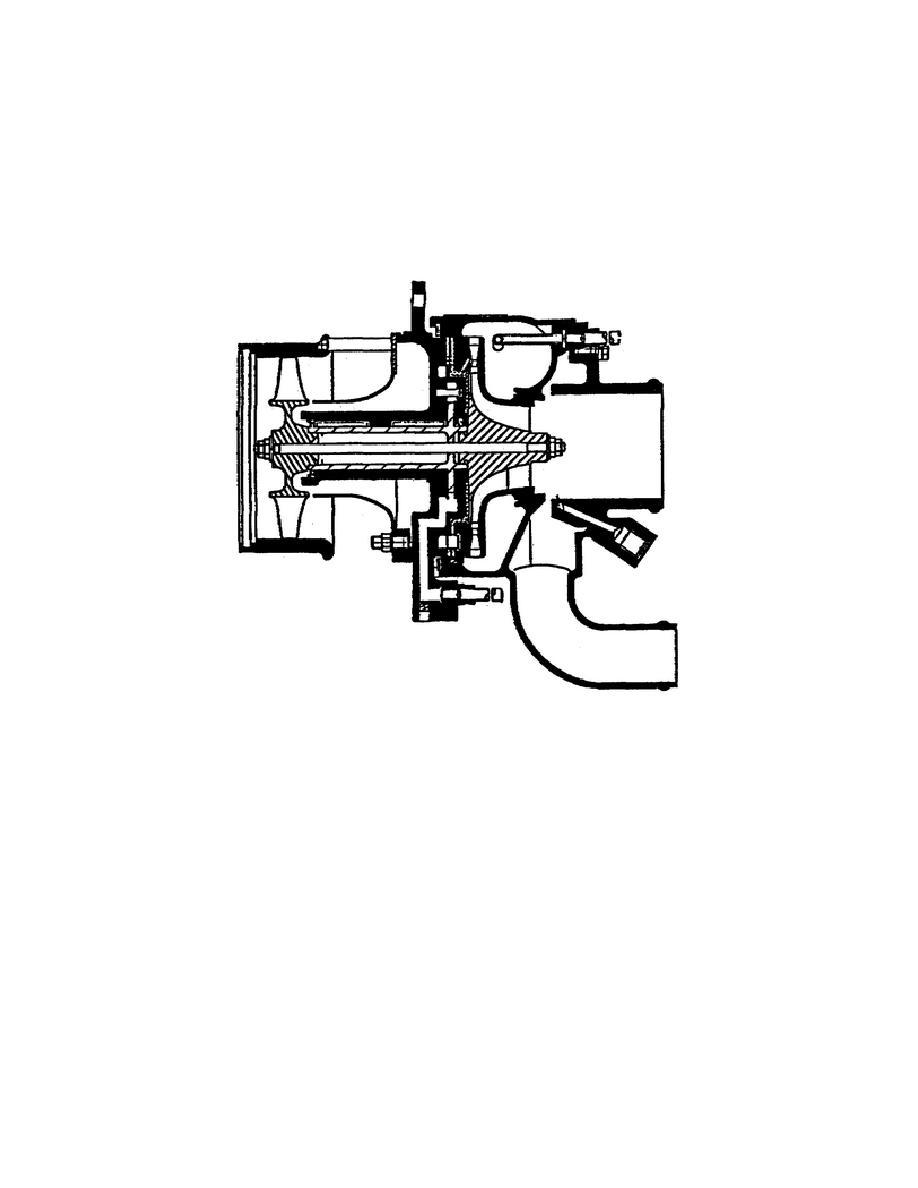

Operation.

The cooling turbine section of the ACM takes

cool high-pressure bleed air leaving the condenser, and

directs it onto the curved blades of the turbine.

As the

air leaves the turbine it expands, resulting in rapid

cooling of the bleed air. As the turbine rotates, energy,

extracted in the form of heat, transfers through the common

shaft to the fan section.

The fan loads the turbine and

draws cooling air across the heat exchanger and through the

precooler.

During maximum cooling, the speed of the ACM

may reach 70,000 rpm (fig. 1-29).

Figure 1-29.

Air Cycle Machine Schematic.

10.

Anti-Ice Temperature Sensor.

The anti-ice temperature sensor mounts in the low pressure outlet

duct of the condenser (fig. 1-30).

This sensor has an electrical

connector, a threaded mounting boss, and a short protruding sensing

probe.

Operation.

The anti-ice temperature sensor senses the

temperature of the turbine discharge air going through the

condenser.

The

sensor

works

with

the

temperature

controller

and

the

anti-ice

valve

to

maintain

the

temperature of the turbine discharge air at 45,F ƒ3,F.

The sensor operates on a negative coefficient which means

if the temperature around the sensor decreases,

25

OD1705

Previous Page

Previous Page