BANDSAW OPERATIONS - OD1646 - LESSON 1/TASK 1

before the band will be too short to fit over the machine wheels.

(b) If it is found, after making the weld, that the teeth of the band

point in the wrong direction, it can be reversed by turning the band inside

out. However, this cannot be done when the band is welded through a piece

of material for internal sawing. In this case, the saw band must be cut and

welded.

(6) Cleaning Up After Welding. It is important that the welder jaws be

kept clean at all times. The jaws and inserts must be wiped and/or scraped

clean after every weld. Doing this will maintain the strength and fatigue

characteristics of the band by holding proper alignment, preventing flash

from becoming embedded in the band, and preventing shorts or poor electrical

contact.

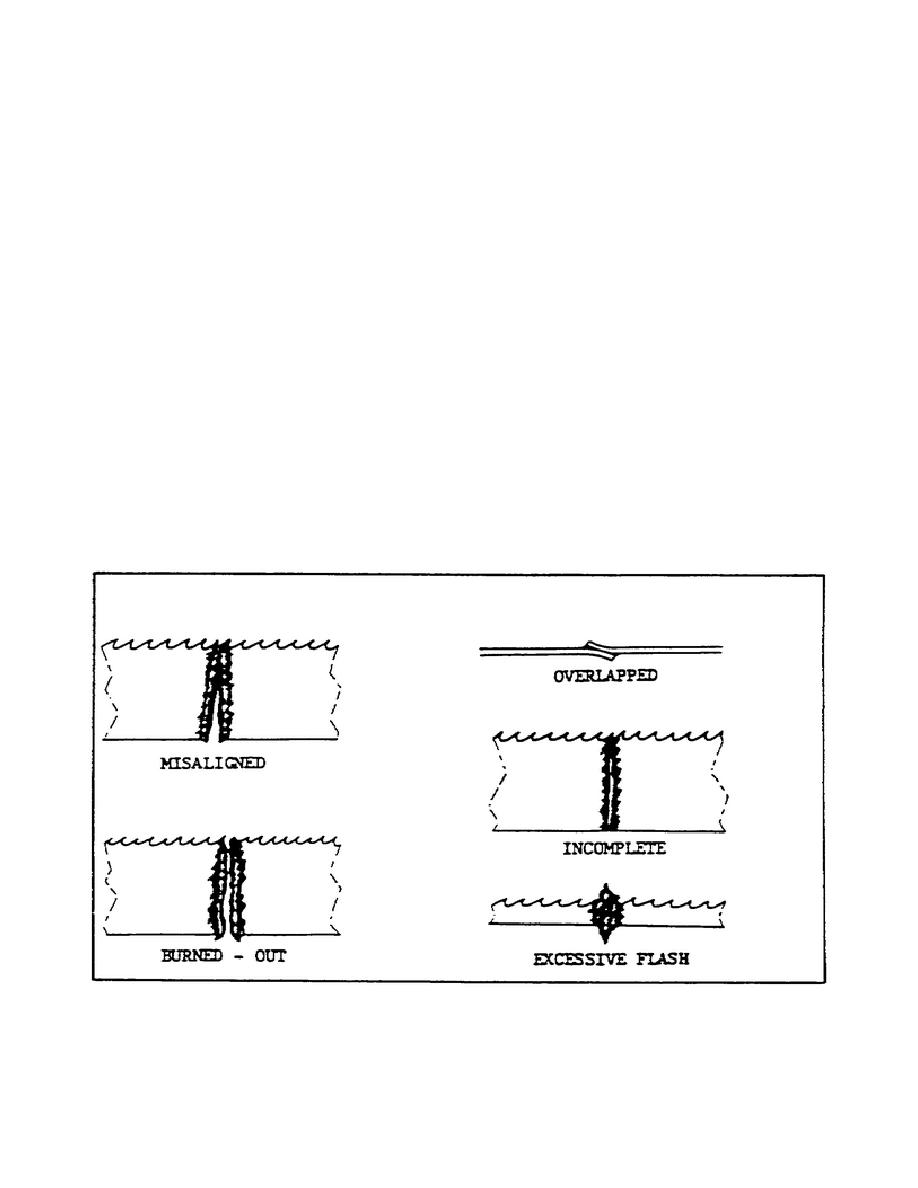

(7) Inspecting the Weld. When the band is removed from the welder, it

should be inspected carefully. The color of the upset material around the

weld should be blue-gray, and of equal intensity throughout. The spacing of

the teeth should be uniform, and the weld should be located in the center of

the gullet. Major jaw misalignment is easily noted at this time from the

weld appearance. Figure 26 shows several types of defective welds. If a

weld is imperfect, some of

FIGURE 26.

DEFECTIVE WELDS.

35

Previous Page

Previous Page