BANDSAW OPERATIONS - OD1646 - LESSON 1/TASK 1

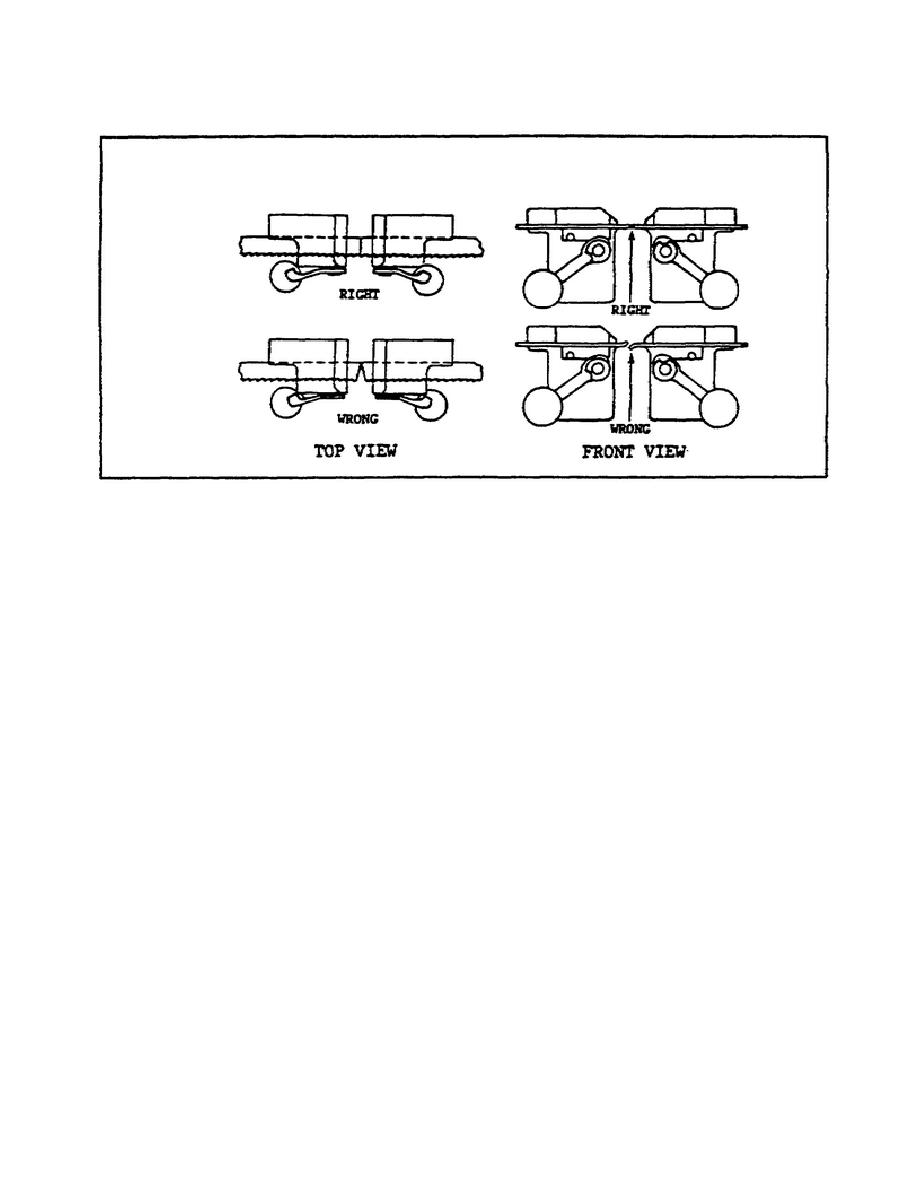

FIGURE 25.

SAW BLADE ALIGNMENT.

(c) If the contact across the width is not complete when the ends are

clamped in the jaws, remove one end and recut it. A misaligned joint will

cause an incomplete weld.

(d) After the blade ends are lined up, clamp them securely, but not so

tightly as to harm the set, between the welder jaws.

(5) Making the Weld. After the blade ends have been aligned, press and

hold down the weld lever (refer to figure 24 on page 32) to make the weld.

The lever should be held down until the weld has cooled. The stationary jaw

clamp should be released before the weld lever is released.

This will

prevent scoring the welder jaw surface. Then release the weld lever. When

the lever is released, the butt welder mechanism and electrical switches

will be automatically recocked, and the band will be ready to be annealed.

Remove the welded saw band. Two general statements about welding the band

should be noted:

(a) Cut out the old weld as each new weld is made. Since only one weld

is recommended in a saw band, use the blade shear to cut away small portions

of the ends of the old weld. Since the welding operation uses up no more

than 1/16 inch of the band, it will not shorten the band appreciably, even

after several welds have been made.

Starting with a full size saw band,

approximately three to four inches of band can be used in making welds

34

Previous Page

Previous Page