LATHE OPERATIONS - OD1645 - LESSON 1/TASK 2

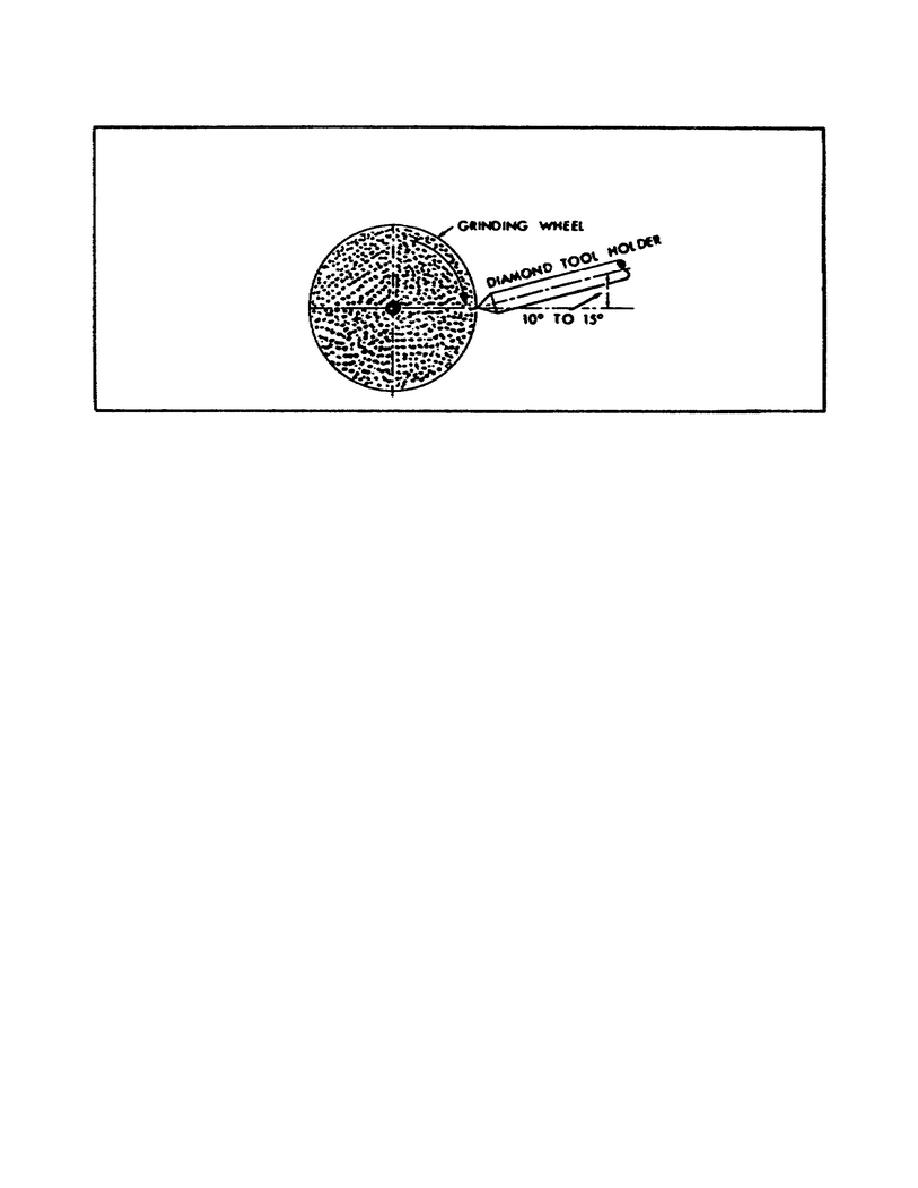

FIGURE 33.

POSITION OF THE DIAMOND DRESSER.

(5) When truing a grinding wheel, bring the center of the wheel face in

contact with the diamond by carefully feeding the cross-slide in by hand.

Move the wheel clear of the diamond and make a cut by means of the cross-

slide. The maximum depth of cut is 0.002 inch. Move the wheel slowly back

and forth over the point of the diamond. Move the carriage if the face of

the wheel is parallel to the ways of the lathe. Move the compound rest if

the face of the wheel is at an angle. Make the final depth of cut of 0.0001

inch with a slow even fed to obtain a good wheel finish. Remove the diamond

dresser as soon as the wheel is dressed properly.

Adjust the grinder to

begin the grinding operation.

(6) Rotate the work at a fairly low speed during the grinding operation.

The recommended surface foot speed is 60 to 100 feet per minute (fpm). The

depth of cut depends upon the hardness of the workpiece, the type of

grinding wheel, and the desired finish. Avoid taking grinding cuts deeper

than 0.002 inch until experience is gained. Use a fairly low rate of feed.

Experience will soon allow one to be able to judge whether the feed is to be

increased or decreased.

Never stop the workpiece or the grinding wheel

while they are in contact with each other.

d.

Selecting the Proper Quill.

Accuracy, quality of finish, and metal

removal rate depend upon the selection of the correct quill for a specific

grinding job. Complete dimensions and specifications of all Dumore quills

appear in the TM 9-3460-215-10. The correct quill should be

80

Previous Page

Previous Page