LATHE OPERATIONS - OD1645 - LESSON 1/TASK 1

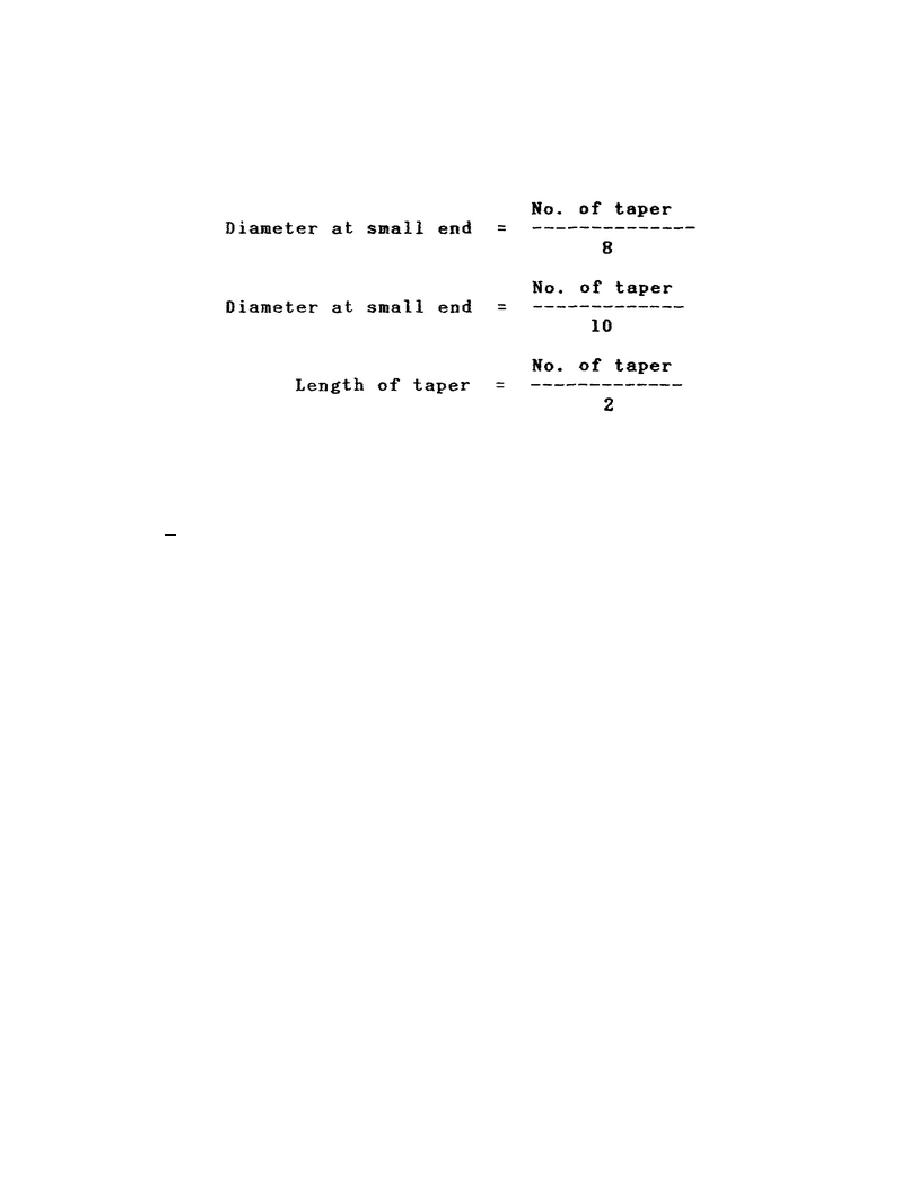

or 0.7 inch in diameter at the small end; and 7/2 or 3 1/2 inches long.

Therefore, formulas for these dimensions would read:

The Jarno taper is used on various machine tools, especially profiling

machines and for die-sinking machines.

It has also been used for the

headstock and tailstock spindles on some lathes.

5 The Standard taper pins are used for positioning and holding

parts together and have a 1/4 inch taper per foot. Standard sizes in these

pins range from No. 7/0 to No. 10. The tapered holes used in conjunction

with the tapered pins use the processes of step-drilling and taper reaming.

(b) To preserve the accuracy and efficiency of tapers (shanks and holes)

they must be kept free from dirt, chips, nicks, or burrs.

The most

important factor in regard to tapers is to keep them clean. The next most

important factor is to remove all oil by wiping the tapered surfaces with a

soft, dry cloth before use, because an oily taper will not hold.

7.

Conclusion

During this task, we have discussed the various types of lathes,

accessories, uses, and some of the lathe operations that the machinist will

encounter in the machine shop.

With proper application, this information

will assist those dealing with lathe operations or the machinists that are

performing these functions in the metalworking field. In task two and three

of this lesson, grinding, milling attachments, and thread forms will be

discussed.

76

Previous Page

Previous Page