USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 3/TASK 1

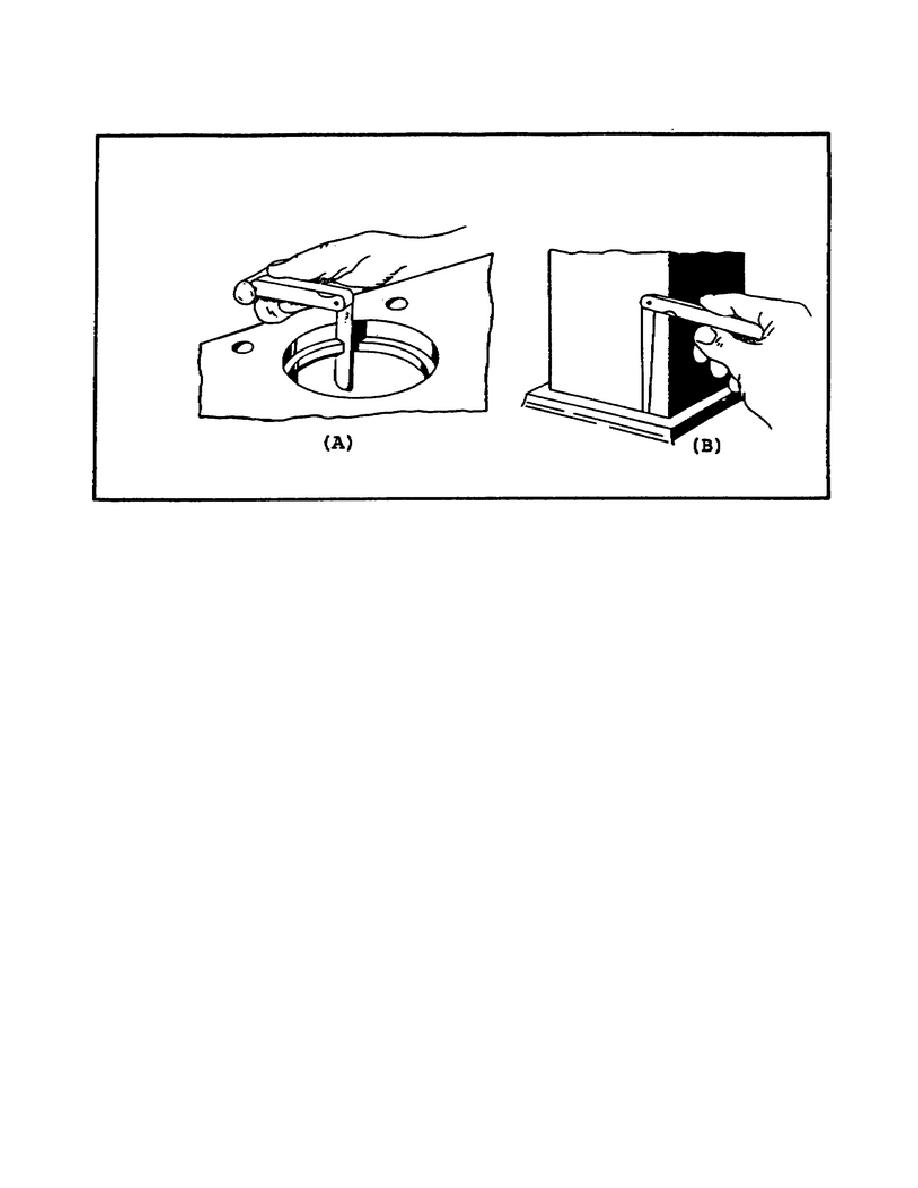

FIGURE 205.

USING THICKNESS (FEELER) GAGES.

j. Use of Thickness (Feeler) Gages. Thickness (feeler) gages are used

in one of two ways, as a means for determining a measure or a means for

adjusting to a definite limit. Figure 205, view A, shows a thickness gage

being used to check piston ring gap clearance in a cylinder bore. A long

blade thickness gage is being used to determine the fit between large mating

surfaces in figure 205, view B.

By combining blades it is possible to

obtain a wide variation of thicknesses.

k. Use of Wire and Drill Gages. The use of a drill gage is shown in

figure 206, view A, on the following page. The size of a drill is being

determined; the drill size or number and decimal size are stamped on the

gage beside each hole. A chart on the gage indicates the correct size of

drill to use for a given tap size. Determine the size of both sheet stock

and wire by using a correct sheet and plate or wire gage, as shown in figure

206, view B.

l. Use of Thread Gages.

(1) Center Gage. Check the angle of thread cutting tools as shown in

figure 207 on the following page.

The gage is also used to check cut

threads and the scales are used to measure threads per inch.

260

Previous Page

Previous Page