USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 2/TASK 2

(r) Square.

The length at the back end of the shank, of square

cross section.

(s) Thread. The helical or spiral formed grooves and teeth of the

tap, with intermittent deep longitudinal flutes, which produce the thread in

a tapped hole.

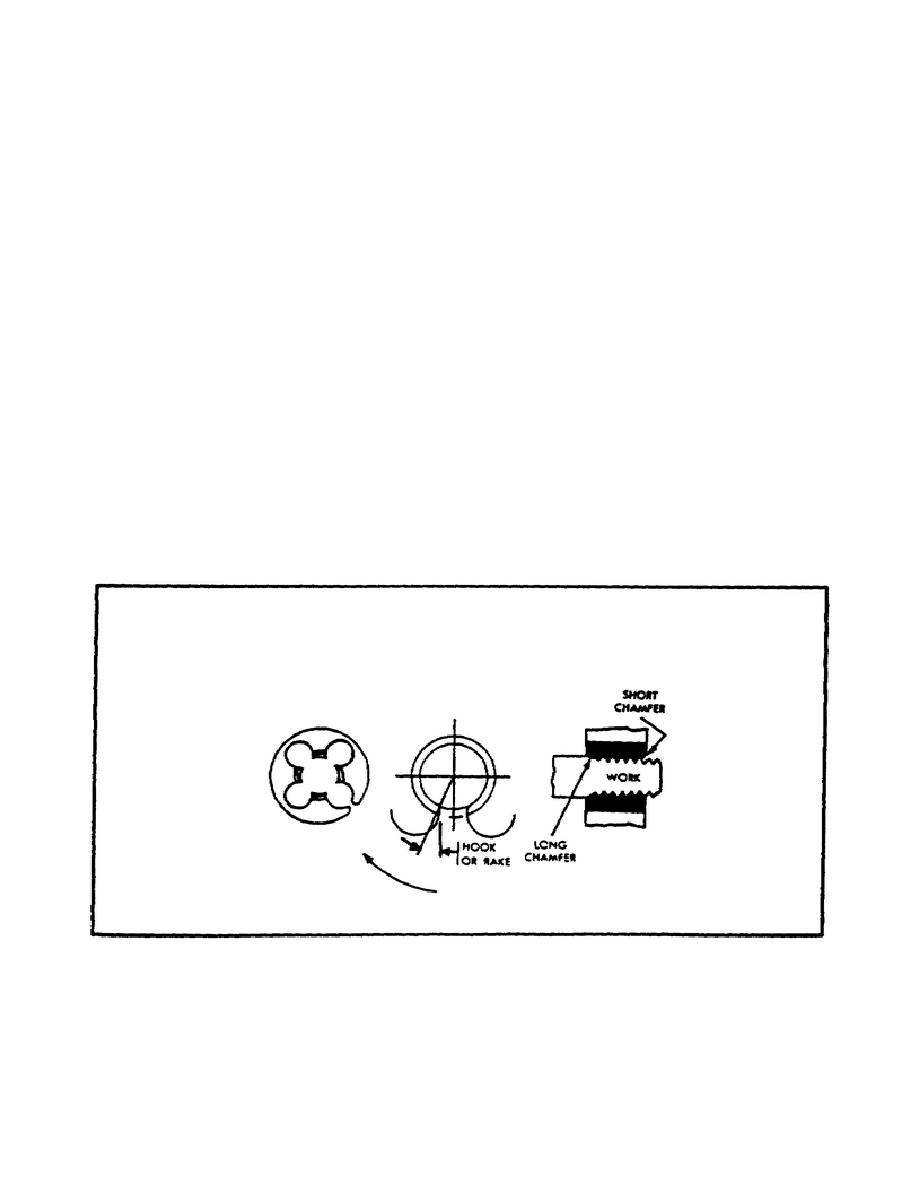

(3) Die Design.

A die is a threading tool designed to produce an

external thread.

It accomplishes this operation without a lead screw.

A

solid die is basically a nut in which flutes have been machined at right

angles to the threads, and which have been hardened to provide cutting

edges. The round or button die is actually an adjustable split nut. Two

piece dies are machined separately. The number of threads in a die is much

less than on a tap and the flutes have more of an exit for the escape of the

chips of metal. A short chamfer on a die (figure 134) is used for threading

close to a shoulder. A long chamfer is used where two or three incomplete

threads can be tolerated on the job to be threaded. Equal chamfering on a

die provides balanced cutting. The terms usually used in connection with a

die are indicated in figure 135 on the following page. The standard chamfer

for the front face of a straight thread die is 2 to 3 threads, or about 15.

The rear face in some dies is chamfered from 1 to 1 1/2 threads. Standard

taper thread dies have a front chamfer of 2 to 3 threads and none at the

rear face. Long chamfers mean better threading performance.

FIGURE 134.

DIE CHAMFERS.

176

Previous Page

Previous Page