USE/CARE Of HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 2/TASK 2

e. Mechanics of Taps and Dies.

(1) General.

Taps and dies are manufactured of regular high speed

steel and surface-treated high speed steel.

Surface-treated high speed

steel taps have a secondary hardening which increases the hardness and wear

resistance of the cutting edges without subtracting from the toughness of

the body of the tool as a whole.

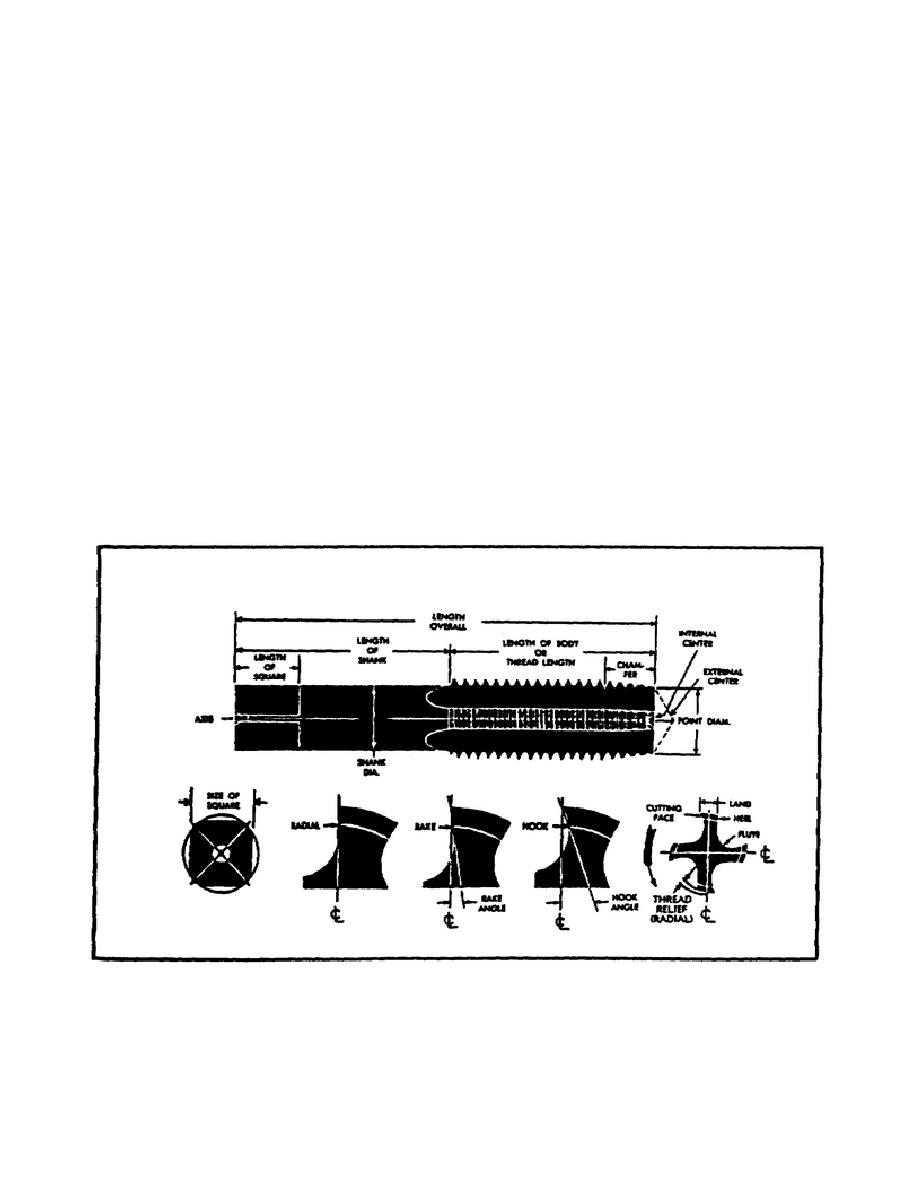

(2) Tap Design.

A tap is a threading tool designed to produce a

completed internal thread and to make threading possible without a lead

screw. A tap is basically a screw in which longitudinal channels or flutes

are cut or ground.

The flutes permit chips to escape and lubricants to

reach the cutting area and threaded metal. Terms used when discussing taps

are as indicated in (a) through (s) below (figure 133).

(a) Axis of Tap.

Longitudinal central through the tap.

(b) Back Taper. A slight taper on the body of the tap which makes

the pitch diameter of the thread near the shank somewhat larger than that

close to the point.

The pitch diameter equals outside diameter minus the

single depth of the thread.

FIGURE 133.

TAP TERMS.

174

Previous Page

Previous Page