USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 2/TASK 2

1/8 inch above the face of the block.

Tighten the clamp screw firmly to

hold the tube in place. Slide the yoke over the end of the die block and

turn the feed screw clockwise until the flaring cone forces the end of the

tube tightly against the chamfer of the die block. The tube is now flared

to a 45 angle. Back out the feed screw, slide the yoke off the die block,

and loosen the clamp screw to remove the flared tube.

(2) Double Flare.

(a) Insert tubing through the proper hole in the die block, with

the end protruding above the block by the thickness of the shoulder on the

appropriate adapter. Tighten the wingnuts on the die block and insert the

adapter in the tubing.

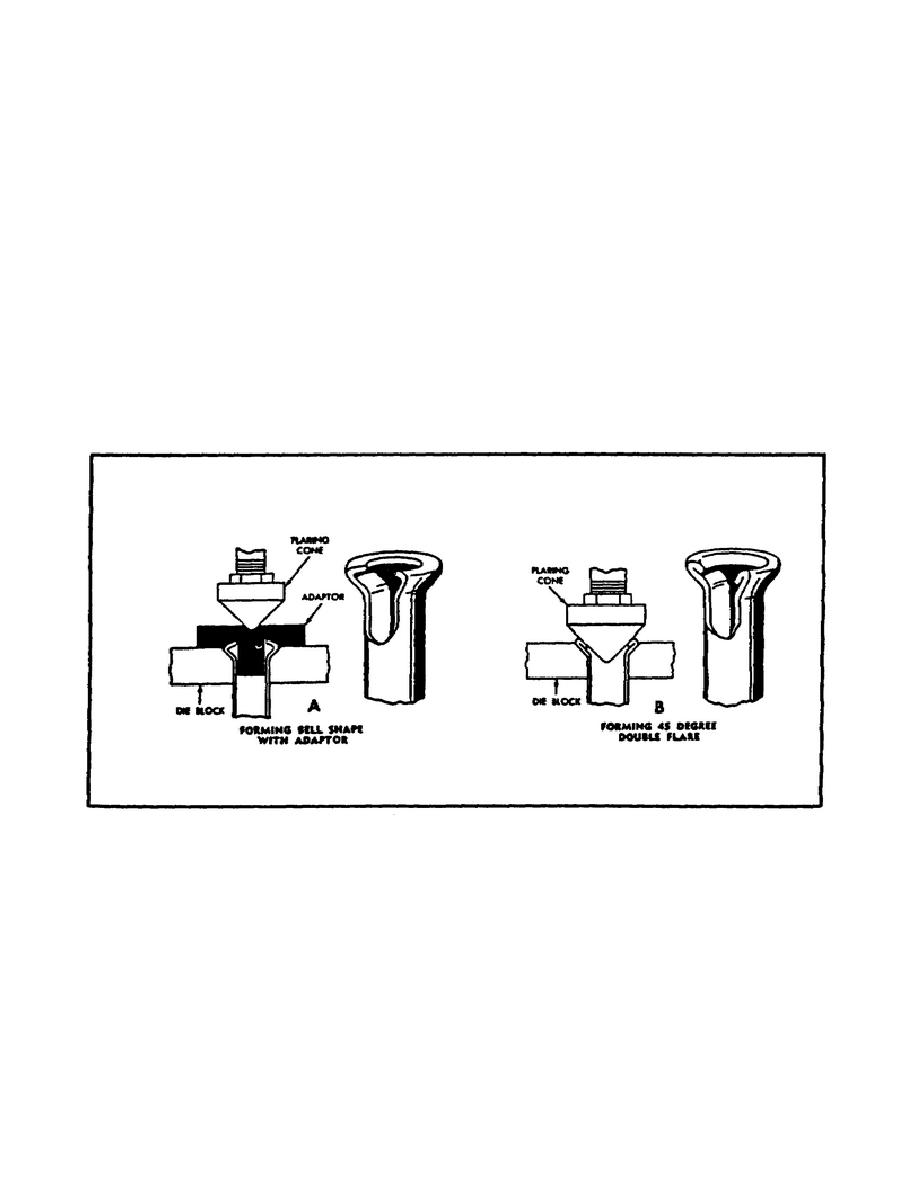

Move the yoke over the adapter and turn the feed

screw clockwise until the shoulder of the adapter rests on the die block and

a bell shape is formed on the tubing, as shown in figure 125, view A.

Loosen the feed screw and remove the adapter from the tubing.

FIGURE 125.

DOUBLE FLARING A TUBE.

(b) Flare tube as you would for a single flare (figure 125, view

8).

f. Care of Cutters and Flaring Tools.

(1) Sharpening Cutter Wheels.

The cutting wheel on a pipe or tube

cutter must be removed and sharpened when it becomes dulled, nicked, or

166

Previous Page

Previous Page