USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 2/TASK 1

an effective insulator to prevent the escape of the heat.

The best method

of securing the work will vary with each job.

(d) The iron must be the right size for the job and must have the

proper temperature. When using an iron to melt solder and heat the work,

the iron loses its heat very rapidly. If an electric iron becomes too cool

to solder, it is too small and a larger iron should be used.

Soldering

small, light objects does not draw a great deal of heat from the iron, but

large castings, pipe fittings, etc., will cool an iron very quickly so that

a torch or flame must be used to preheat the work before the iron is

applied.

In some cases, soldering can be done with a torch alone,

eliminating the iron.

(e) The iron must be kept well tinned and clean.

The electric

iron must be wiped with a rag frequently, and the nonelectric iron wiped

clean after it is removed from the flame.

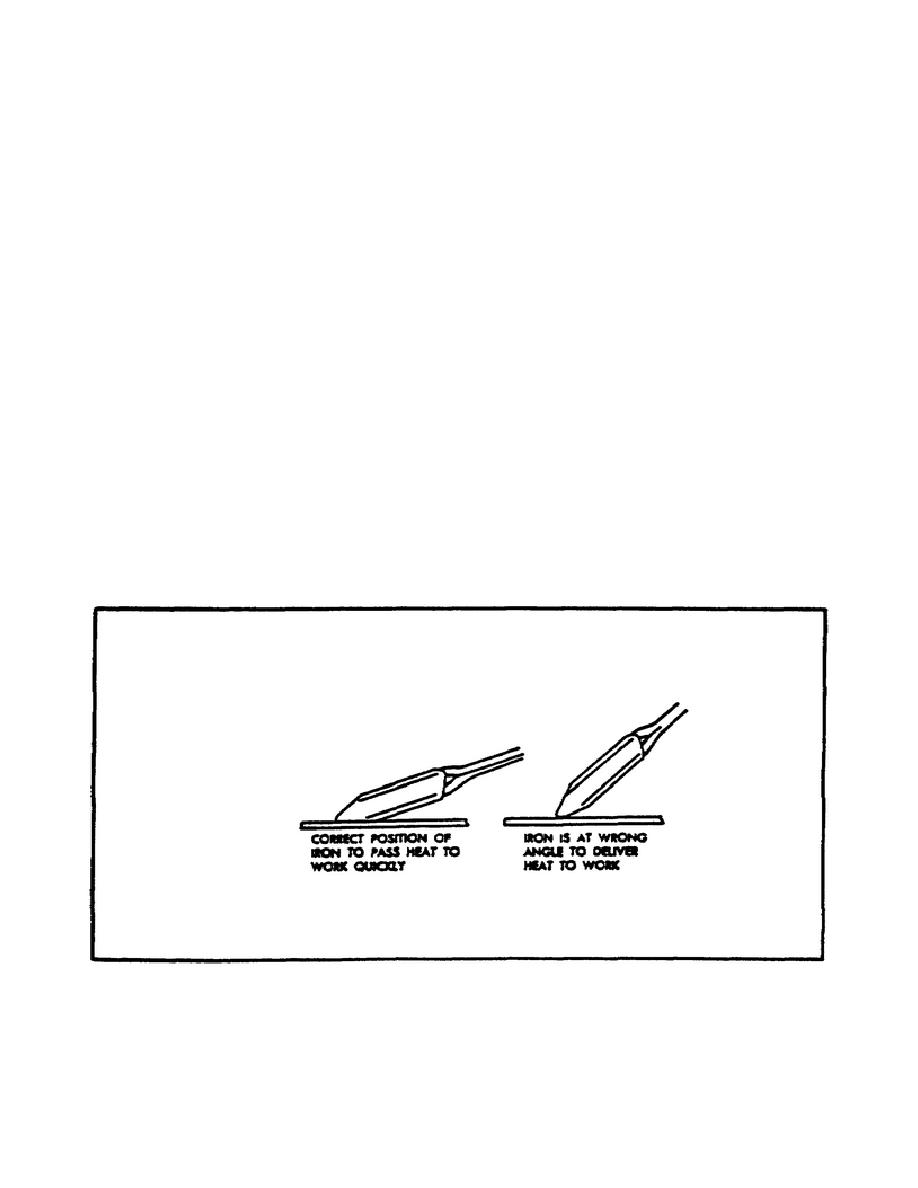

(f) The work must be heated by the soldering iron so that the

solder flows or sweats into the joint. The proper method of holding an iron

to pass heat quickly to the work is by establishing sufficient contact

surface, as shown in figure 60. When soldering splices in wire, the splice

is usually heated by the iron from below and the solder placed above the

splice.

Figure 61 on the following page illustrates the right and wrong

methods to make wire splices for soldering.

FIGURE 60.

POSITION OF IRON TO PASS HEAT.

80

Previous Page

Previous Page