(3) Flaring tools. Flaring tools (fig 18) are used to flare soft copper,

brass, or aluminum to make up 45 flare joints. The single flaring tool consists

of a split die block that has holes for 3/16-, 1/4-, 5/16-, 3/8-, 7/16-, and 1/2-

inch o.d. tubing, a clamp to lock the tube in the die block, a yoke that slips over

the die block that has a compressor screw, and a cone that forms a 45 flare or a

bell shape on the end of the tube. The screw has a T-handle. A double flaring

tool has the additional feature of adapters that turn in the edge of the tube

before a regular 45 double flare is made. It consists of a die block with holes

for 3/16-, 1/4-, 5/16-, 3/8-, and 1/2-inch tubing, a yoke with a screw and a

flaring cone, plus five adapters for different size tubing all carried in a metal

case.

c. Use of pipe cutters.

Before cutting pipe, make certain the required

correct length is determined.

(1) Mark the spot where the cut is to be made with a scriber, file, chalk,

or crayon.

(2) Lock the pipe tightly in the vise with the cutting mark approximately 8

inches from the vise. This distance will vary according to the space required by

the die stock to be used for threading.

(3) Open the jaws of the pipe cutter by turning the handle counterclockwise.

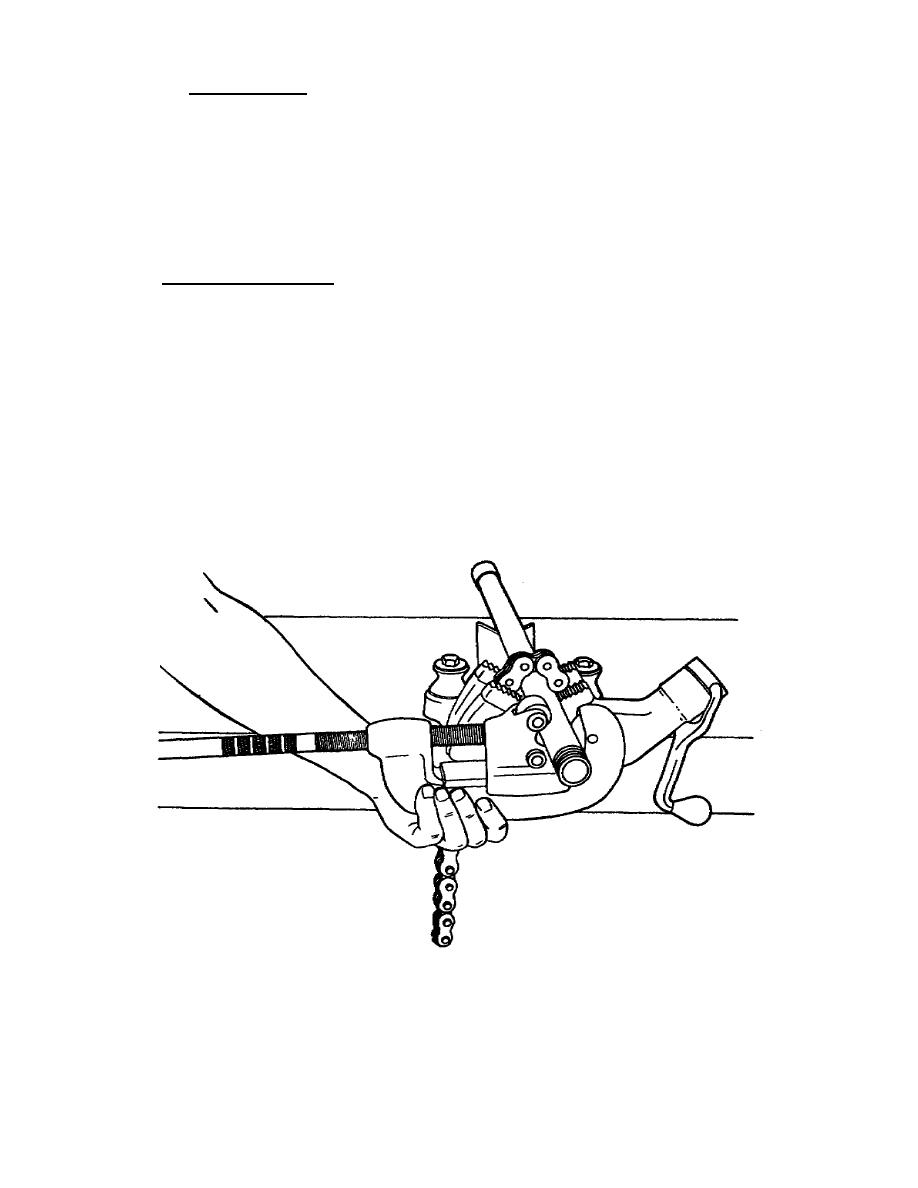

(4) Place the cutter around the pipe from underneath (fig 19) with the

cutting wheel (single-wheel cutter) exactly on the mark. The rollers of the

single-wheel cutter insure a straight cut. If a three-wheel cutter is used, place

the cutting wheel of the movable jaw on the mark and make sure that all three

wheels lie level at right angles to the centerline of the pipe.

Figure 19.

Cutting pipe.

68

Previous Page

Previous Page