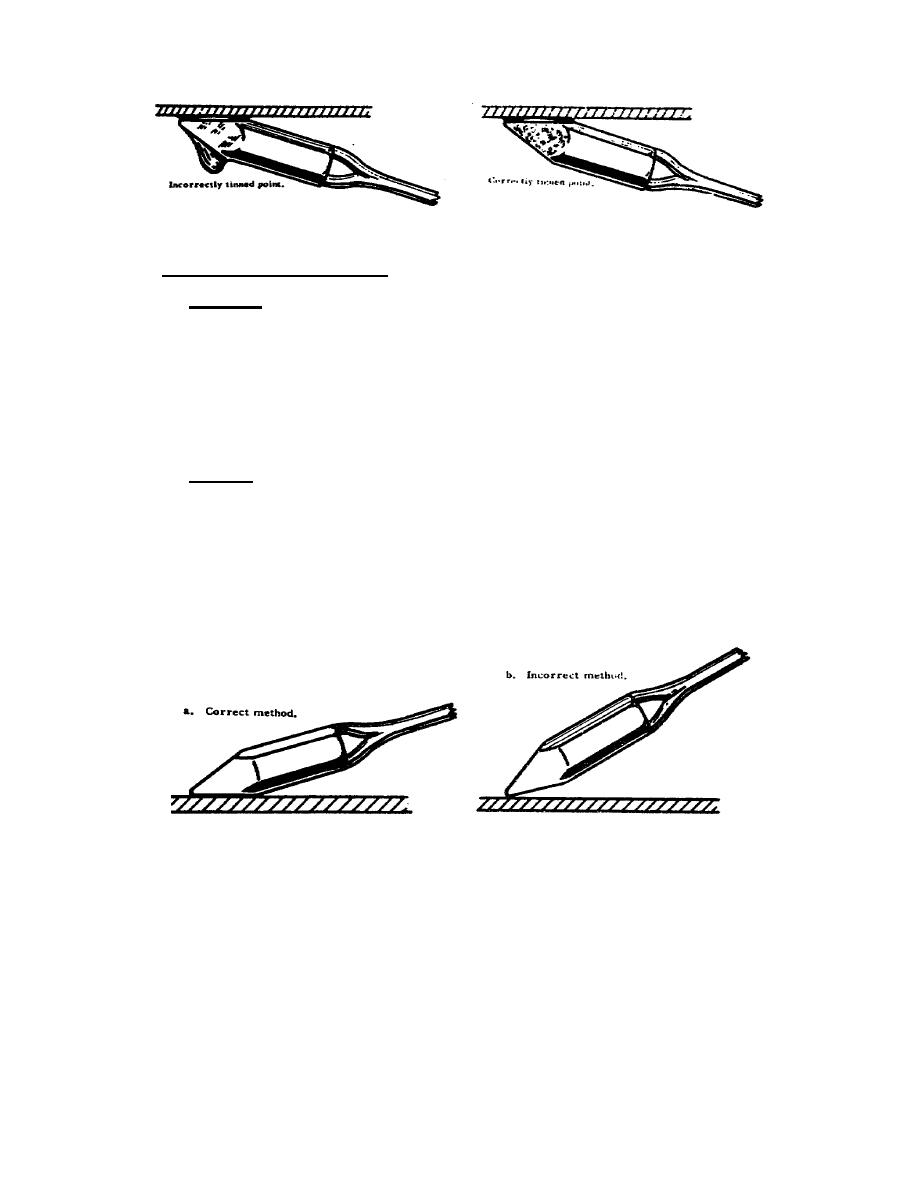

Figure 24.

Iron tinned for working on underside:.

c. Preparing the job surface.

(1) Cleaning. Cleaning the surfaces to be joined is an important step in

soldering operations. If soldering is not already made impossible by the presence

of dirt, rust, corrosion, oil, or grease, any bond obtained will be seriously

weakened. Cleaning may be done with a scraper, file, wire brush, emery cloth, or

sandpaper. For heavily oxidized surfaces, a solution of muriatic (diluted

hydrochloric) acid may be used as a cleaning agent. Cleaning should be considered

satisfactory when the portion of the bare metal to be soldered shows a smooth

bright surface. The cleaned surface of the metal should not be touched because

that will leave a grease stain or perspiration mark that is sufficient to keep the

solder from adhering properly.

(2) Fluxing.

(a) To stop the formation -of additional oxide, the cleaned metal surface

should immediately be protected from the atmosphere with a coating of flux. The

metals to be soldered should be heated by holding the soldering iron flat against

the surfaces of the joint as shown in figure 25. A small amount of flux should

then be applied to the surfaces of the heated metals. Only a small amount of flux

is necessary because when applied to heated metals it spreads rapidly. Liquid flux

can be applied with a small brush, swab, or squirt can.

Figure 25.

Correct and incorrect methods of using cored solder.

142

Previous Page

Previous Page