(3) Face-to-end measure. Face-to-end measure (2, fig 10) is also used for

a piece of pipe having a fitting screwed on one end only. The pipe length is equal

to the measurement plus the length of thread engagement.

(4) Center-to-center measure. Center-to-center measure (3, fig 10) is used

for a length of pipe which has fittings screwed on both ends. The pipe length is

equal to the measurement minus the sum of the end-to-center dimensions of the

fittings plus twice the length of thread engagement.

(5) Face-to-face measure. Face-to-face measure (3, fig 10) is used in the

same situation as (4) above. The pipe length is equal to the measurement plus

twice the length of thread engagement.

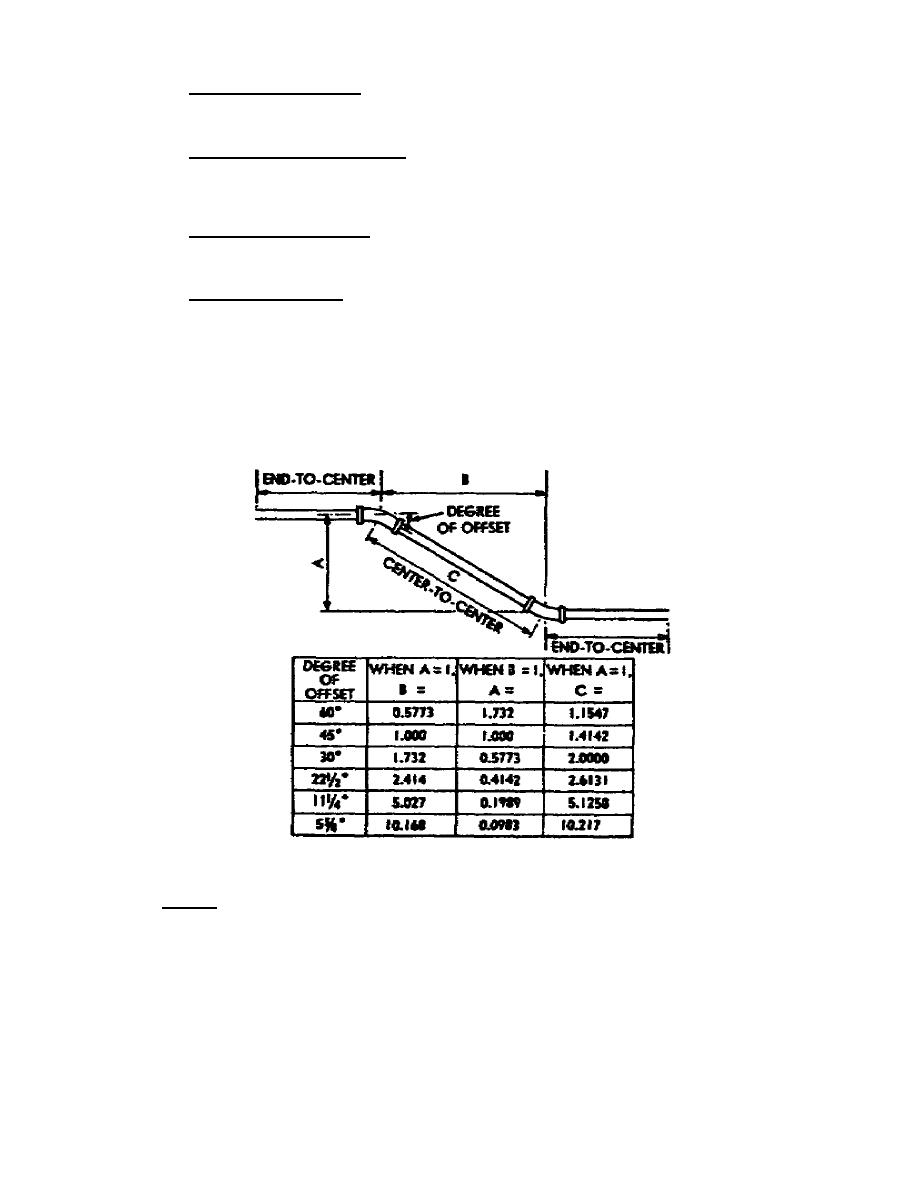

(6) Measuring offsets. Figure 12 and the following procedure explain how to

run an offset. For example, a 45 offset with a 3-inch pipe is to be measured;

the distance between the parallel runs A (center-to-center of pipe) is 40 inches.

Then, from figure 12, distance C (center-to-center of the 45 elbows) is 40 times

1.4142, or about 56-9/16 inches. A standard 3-inch 450 elbow is 4-5/8 inches end-

to-center and, from figure 11, requires a 1-inch thread engagement. Nine and one-

quarter inches (2 x 4-5/8) are deducted and 2 inches for two thread engagements are

added. This results in an end-to-end length of pipe of 49-5/16 inches.

Figure 12.

Pipe measurement for offsets.

b. Tubing.

Copper tubing is measured in the same way as threaded pipe.

Allowance is made for fitting dimensions (solder or compression type) and for the

distance the tubing is inserted into the fitting. Offsets for rigid type tubing

are determined in the same way as for threaded pipe. Since flexible tubing is

easily bent, fittings for offsets are usually unnecessary.

62

Previous Page

Previous Page