MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 1

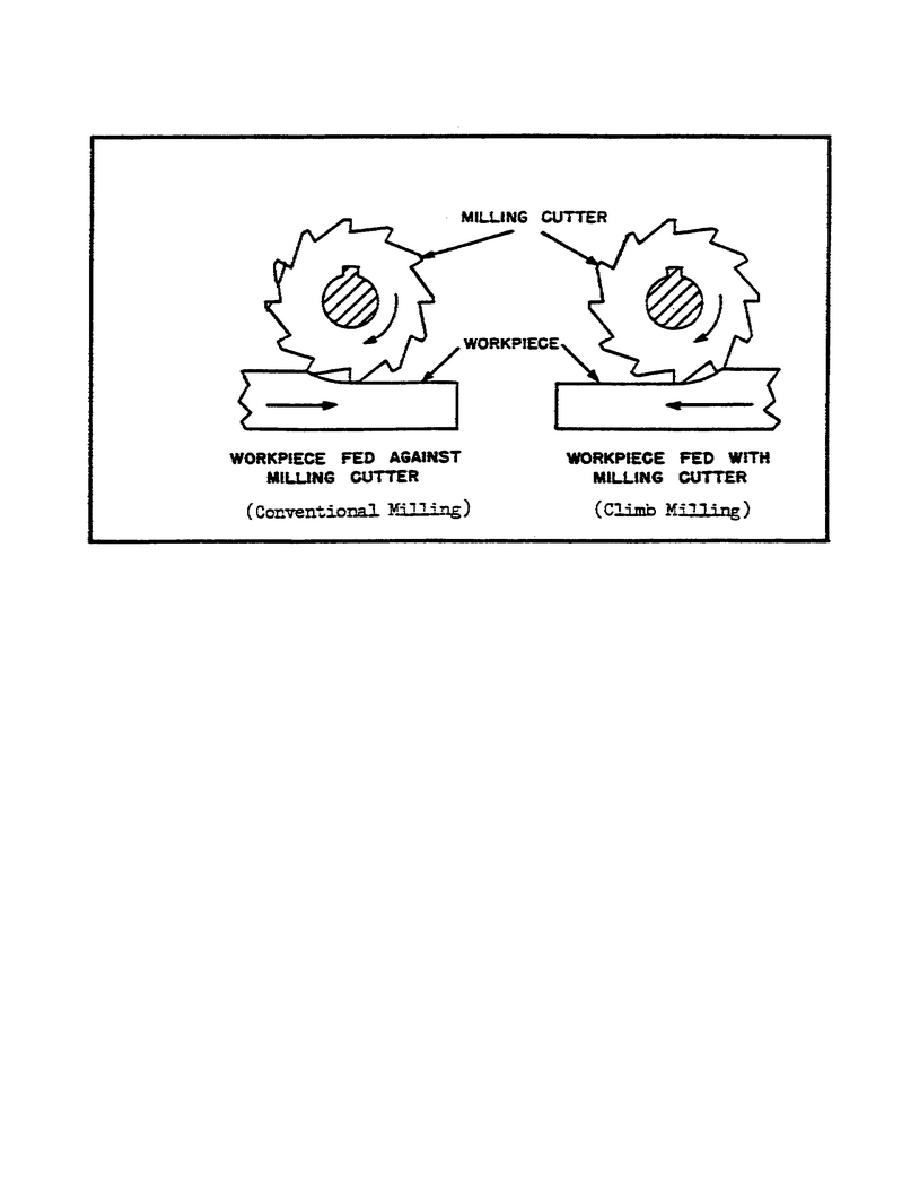

FIGURE 12.

DIRECTION OF FEED FOR MILLING.

also serves to lubricate the cutter face and to flush away the chips,

consequently reducing the possibility of marring the finish.

(2)

Cutting oil compounds for various metals are given in table 3 on the

following page. In general, a simple coolant is all that is required for

roughing.

Finishing requires a cutting oil with a good lubricating

properties to help produce a good finish on the workpiece.

Aluminum and

cast iron are almost always machined dry.

(3)

The cutting oil or coolant should be directed, by means of a coolant

drip can or a pump system, to the point where the cutter contacts the

workpiece. Regardless of the method used, the cutting oil should be allowed

to flow freely over the workpiece and the cutter.

f.

(1)

General.

Plain milling, also called surface milling and slab

milling, is milling flat surfaces with the milling cutter axis parallel to

the surface being milled. Generally, plain milling is accomplished with the

workpiece surface mounted to the milling machine table and the milling

cutter mounted on a standard milling machine arbor. The

34

Previous Page

Previous Page