WELDING OPERATIONS I - OD1651 - LESSON 1/TASK 2

by 1/4 inch stainless steel bar which is placed in the damaged

portion of the armor plate.

It is then bead welded in place.

The principal advantages of this joint are its simplicity, and

good structural and ballistic properties.

Care should be taken

that no welding is done on the hard face side of the armor plate.

c.

Armor Plate Welding Electrodes.

(1) The most satisfactory method for the repair of homogeneous

and face hardened armor plate is the arc welding process with

stainless steel electrodes.

(2) In the oxyacetylene welding process, a large section of

base metal must be heated to maintain a welding puddle to weld

satisfactorily. This heating destroys the heat treatment of the

base metal, causing large areas to become structurally and

ballistically weak.

In addition, this process is slow and

produces considerable warpage of the base metal.

(3) Initially, developments in armor plate welding required the

use of stainless steel electrodes containing 25 percent chromium

and 20 percent nickel.

Further developments served to produce

electrodes with a core of 18 percent chromium and 8 percent

nickel, and a coating of manganese or molybdenum, or both, which

produce excellent results.

These electrodes are known as

manganese modified 18-8, and molybdenum modified 18-8 stainless

steel electrodes.

They can be used for welding all types of

armor plate by the electric arc process without preheating or

postheating the base metal structure.

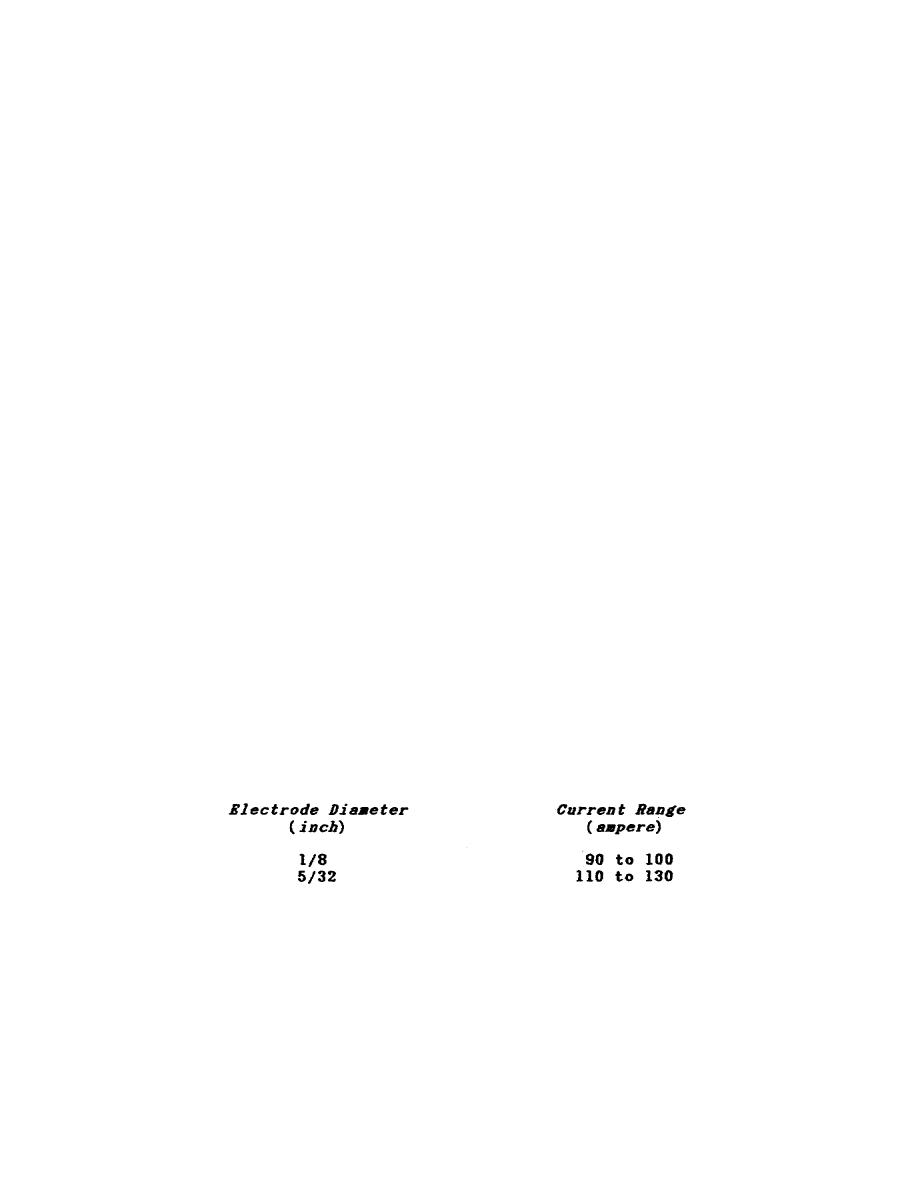

(4) Current and Polarity.

The exact current required for arc

welding with the electrodes previously discussed depend to some

extent on the joint type, electrode design, and position of

welding.

Listed below are the recommended welding current

settings listed for direct current reverse polarity, all

position, heavy coated, modified 18-8 stainless steel electrodes.

91

Previous Page

Previous Page