WELDING OPERATIONS I - OD1651 - LESSON 1/TASK 1

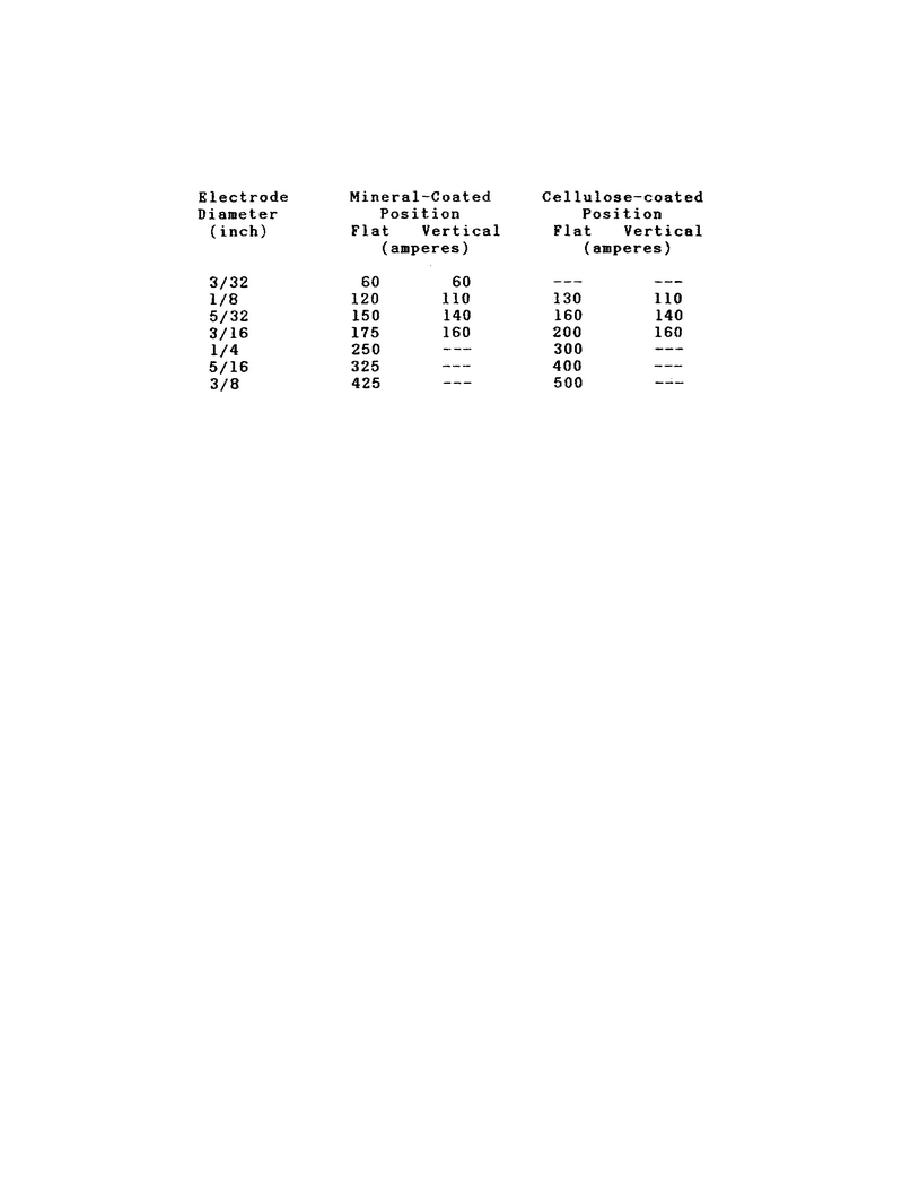

TABLE 2. CURRENT SETTINGS FOR MINERAL AND

CELLULOSE COATED ELECTRODES.

(4) In preparation for welding, the welding machine must be

adjusted to provide proper welding conditions for the particular

size and type of electrode being used. These adjustments include

proper polarity, as well as current and voltage settings.

The

dual-control machines make possible the separate control of

voltage and current that is delivered to the arc.

In single-

control units, the welding current is controlled manually while

the voltage is adjusted automatically.

(5) When proper adjustment of the welding machine is obtained,

the exposed end of the electrode should be gripped in the

electrode holder so that the entire usable length can be

deposited, without breaking the arc. In some cases, when welding

with long electrodes, the center of the electrode is bared and

gripped in the center. Carbon and graphite electrodes should be

gripped short of the full length to avoid overheating the entire

electrode.

c.

Starting the Arc (figure 12 on the following page).

(1) The following are two methods used for starting the arc:

(1) the striking or brushing method shown in figure 12, view A,

and (2) the tapping method shown in figure 12, view B. In both

methods, the arc is formed by short circuiting the welding

current between the electrode and the work surface. The surge of

high current causes both the end of the electrode and a small

spot on the base metal beneath the electrode to melt instantly.

30

Previous Page

Previous Page