PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

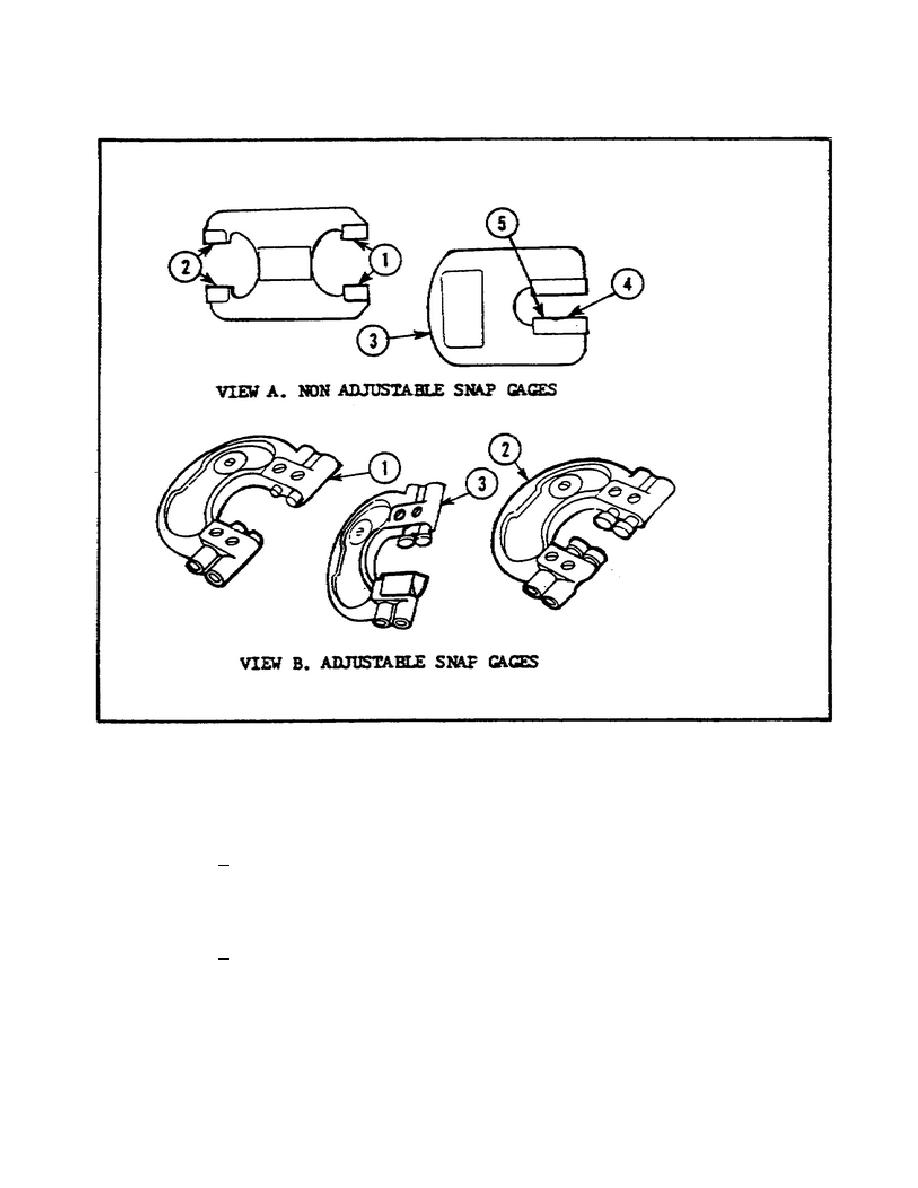

FIGURE 14.

SNAP GAGES.

(d) Using an Adjustable Snap Gage. Before the snap gage is used

to check parts, the GO and NO GO buttons, pins, or anvils must first be set

to the proper dimensions (figure 15, views A through D, on the following

page indicate the steps used for making the proper settings).

1 To make the proper settings, the snap gage should be

clamped in a vise (soft jaws) or a holder (figure 15, view A). Adjust the

GO dimension first or, if desired, reverse the procedure and adjust the NO

GO dimension first.

2 After determining the correct dimension, the gage should be

set. Select a master disk, a precision gage block, or a master plug of the

correct size. Loosen the locking screw (2) (figure 15, view B), and turn

the adjusting screw (3) until the dimension (4) is set.

25

Previous Page

Previous Page