LATHE OPERATIONS - OD1645 - LESSON 1/TASK 3

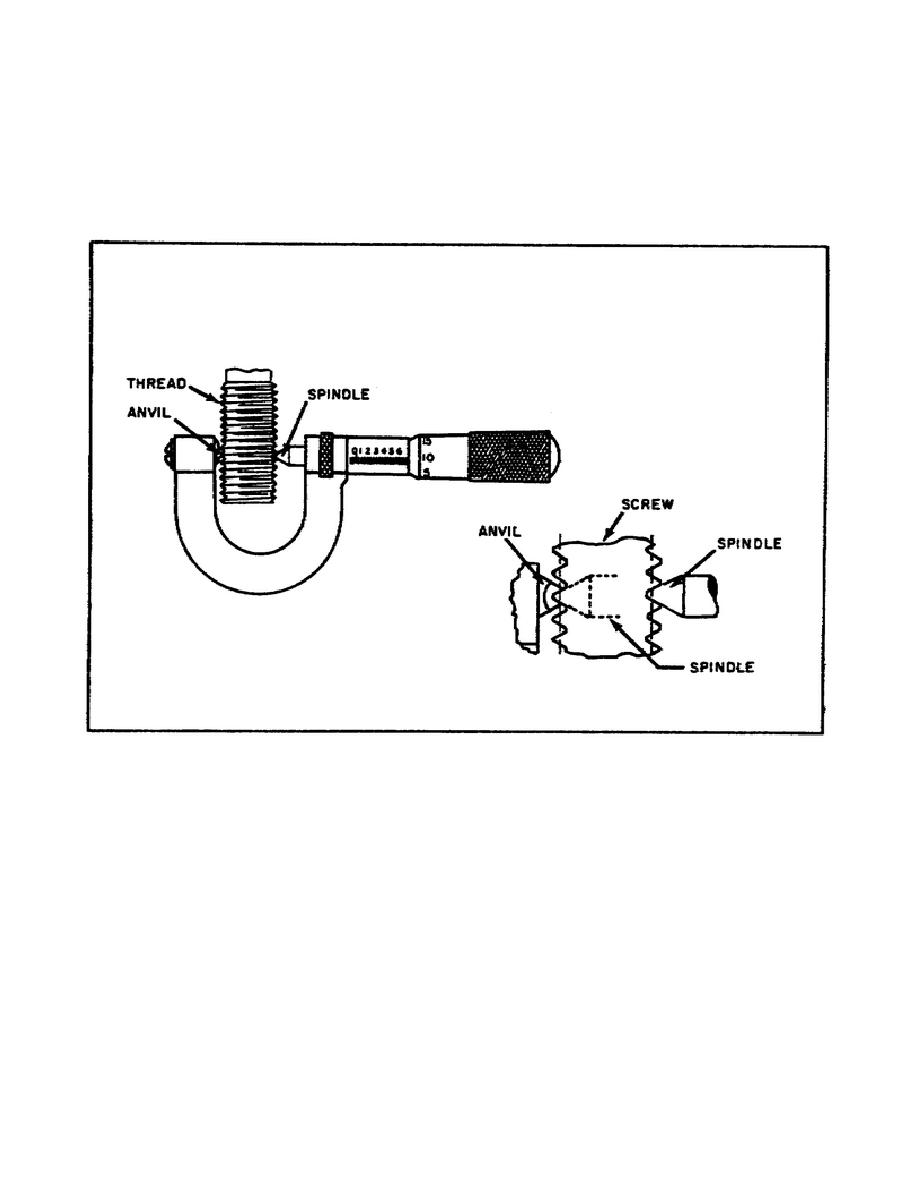

The procedure used in checking the accuracy of the thread is to first select

the proper micrometer, then calculate or select from a table of threads, the

correct pitch diameter of the screw.

Lastly, fit the thread into the

micrometer and take the reading.

FIGURE 47.

THREAD MICROMETERS.

(3) The ring gage (female)(figure 48 on the following page) is screwed

onto the thread after it is cut. It checks the completed thread against a

standard mating part. By means of a ring gage, the oversize and undersize

sections of a thread can be found.

Ring gages are made in a variety of

sizes and fits. The gage must be carefully chosen to control the desired

limits for each thread as determined by the design engineer. Overly close

limits mean high manufacturing costs, while overly wide limits cause

assembly failures. Gages should be selected in accord with the class of fit

for which they are used. For example: if a blueprint calls for 9/16-12UNC-2

thread, it means that the ring gage needed will have a major diameter of

9/16 inch, with 12 threads per inch of the Unified National coarse type, and

it should have a class 2 fit.

121

Previous Page

Previous Page