LATHE OPERATIONS - OD1645 - LESSON 1/TASK 1

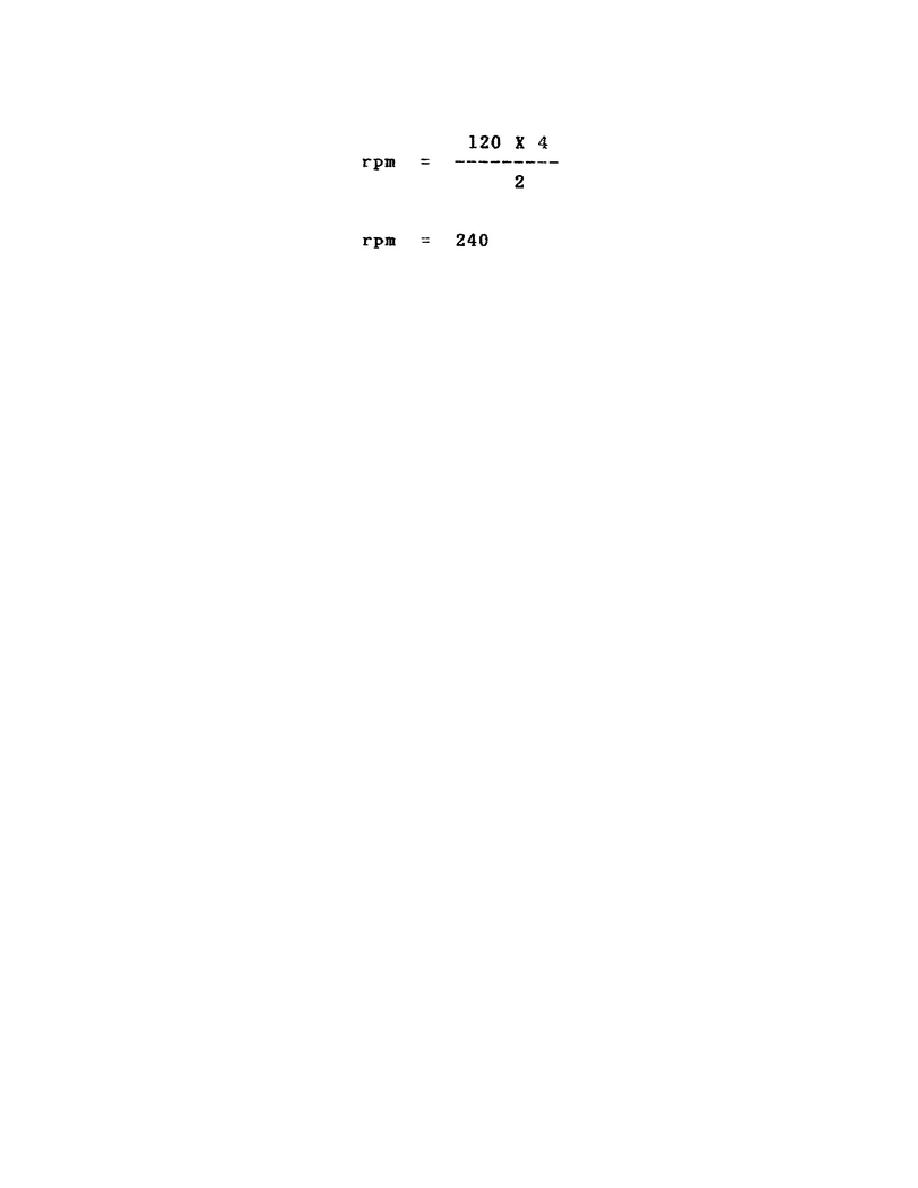

Spindle speeds for drills and other rotating cutters can be determined using

the same formula by substituting the cutter diameter of the drill or cutter

for the diameter of the workpiece. Table 2 on page 49 may be used to save

time when computing rotational spindle speeds for common cutting speeds and

common workpiece diameters.

(d) Another factor to consider when selecting cutting speed includes the

use of cutting oils, the length and diameter of the workpiece, and the

condition of the lathe. If a large stream of proper cutting oil is applied

to the workpiece at the cutter bit, the cutting speed can be increased as

much as 40 percent.

If the diameter of the workpiece is small and its

length is great enough to set up vibrations due to the speed, a poor finish

will result; to correct this condition, the speed must necessarily be

reduced. The lathe may also be in poor condition so that high speeds will

cause harmful vibrations.

(e) The technical manual for the lathe being used should be consulted

for instructions in setting spindle speed for operation.

If a desired

spindle speed is not available on the lathe, select a speed nearest that

which is desired, generally the first slower speed that is available. For

efficient lathe operation, the machinist should be able to recognize too

slow a speed as well as too fast a speed.

(3) Feed.

(a) General.

Feed is the term applied to the distance the cutter bit

advances for each revolution of the workpiece. Feed is specified in inches

per revolution. Since the best feed depends upon a number of factors such

as depth of cut, type of material, size of workpiece, and condition of the

lathe, it is difficult to list the best feed for the different materials.

52

Previous Page

Previous Page