METAL PROPERTIES, CHAR, USES, AND CODES - OD1643 - LESSON 1/TASK 1

It is possible, by varying the carbon content and by proper heat

treatments, to alter properties from a very soft, workable steel, of

the type used in pressed metal parts, wire, and similar materials, to

hard, strong steel, suitable for use in tools, machinery, and armor,

where great strength and hardness are necessary.

(5) Cast Iron.

Cast iron is produced by melting a certain

quantity or charge of pig iron, limestone, and coke in a cupola

furnace.

It is then poured into sand or alloy steel molds, and

allowed to cool at room temperature. Cast iron is basically an alloy

whose chief elements are iron, silicon, and carbon. The material is

available with a wide range of properties. Pig iron, gray cast iron,

white cast iron, chilled cast iron, and malleable cast iron are all

referred to as cast iron.

(6) Wrought Iron.

This is the oldest form of iron made by man.

It is a metal that contains high purity iron and iron silicate. It

is very low in carbon with the iron silicate or slag distributed

throughout the base metal in fibers. These fibers give the material

a woody or stringy appearance when broken.

(7) Differences Between Cast Irons and Steels.

(a) All the various forms of cast iron, steel, and wrought iron

consist of chemical compounds and mixtures of iron, carbon, and

various other elements in small quantities.

Whether the metal is

classified as cast iron or as one of the steels depends entirely upon

the amount of carbon in it.

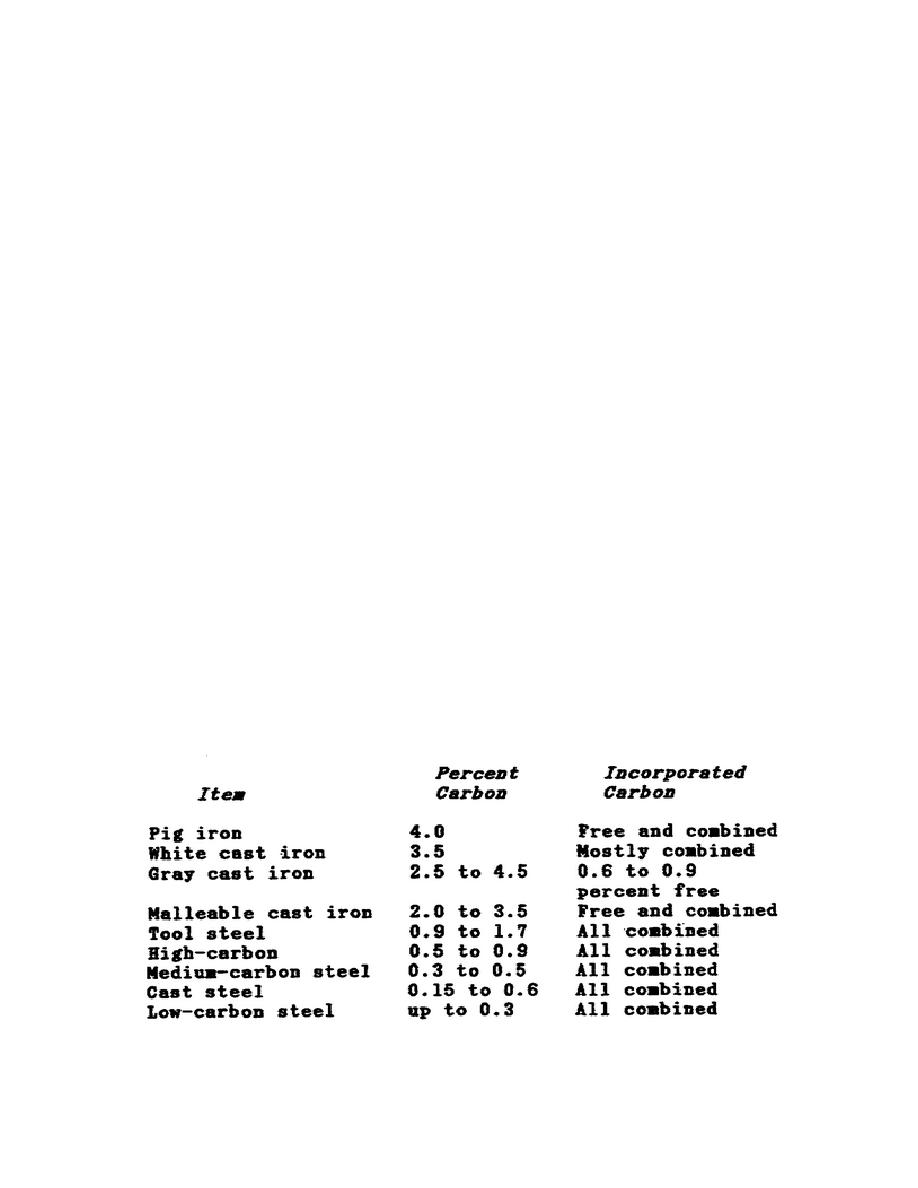

The following table illustrates this

principle:

11

Previous Page

Previous Page