USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 3/TASK 1

casting, molten metal is poured into a cavity formed in sand by a wooden or

metal pattern of the part.

The impression in the sand is that of the

pattern and is of the same size and shape.

The molten metal fills the

cavity, solidifies, and cools.

As all metals expand when heated and

contract when cooled, the casting shrinks as it cools, and becomes smaller

than the cavity. To compensate for this shrinkage so that the casting will

be the correct size when it cools, the pattern must be made larger than the

part itself. So, in making the pattern, using the blueprints of the part,

it is necessary for the patternmaker to add just the correct amount to every

dimension to take care of shrinkage. Rather than calculate this shrinkage,

the patternmaker uses a shrink rule, which automatically compensates for it.

Every metal has its specific shrinkage value; the expansion or contraction

for each degree change in temperature is not the same.

Shrinkage for the

two most common casting metals are: iron - 1/8 inch per foot; brass - 3/16

inch per foot. A special shrink rule is required for each of these casting

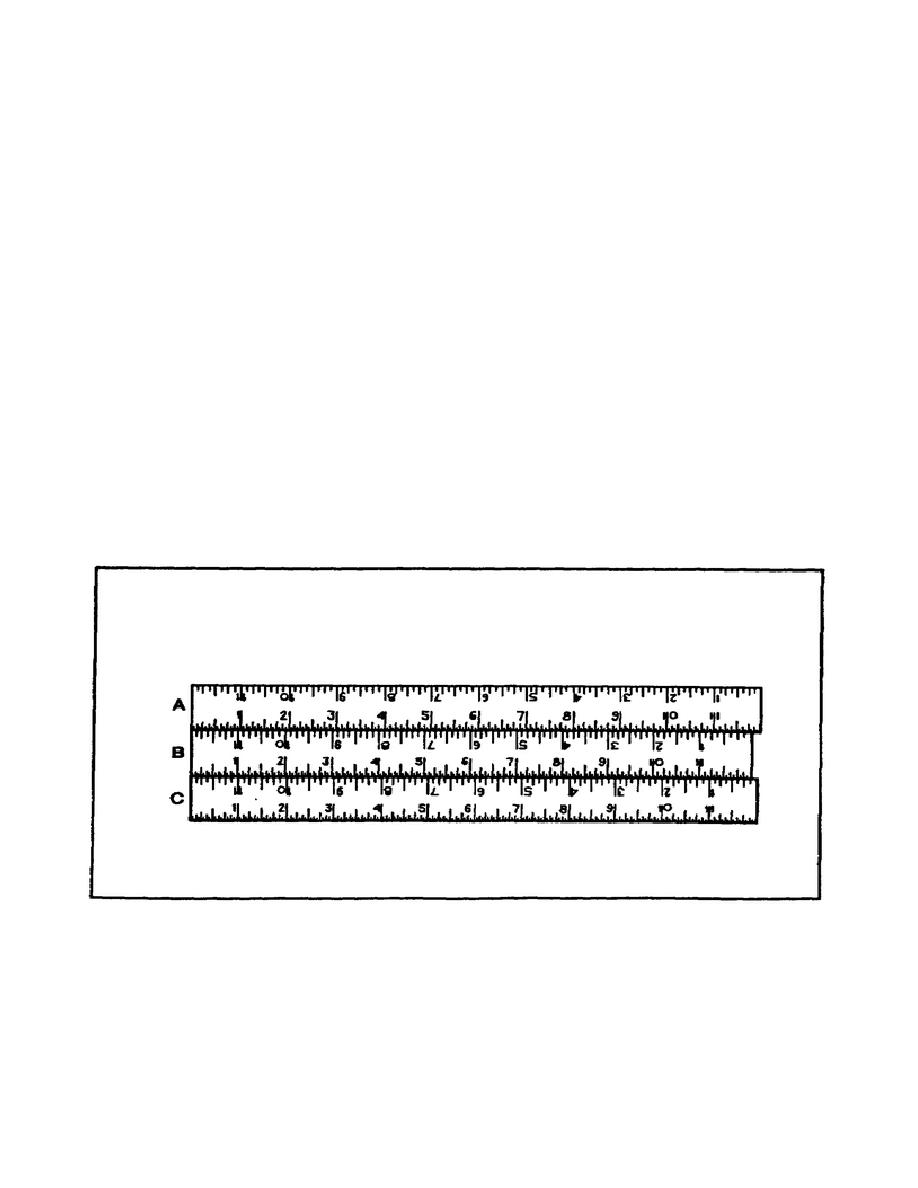

metals. In figure 165, two shrink rules, A for brass and C for cast iron,

are shown in comparison with a standard foot rule, B. Note that the inch

marks on the shrink rule do not match the corresponding marks on the

standard rule, and that this variation increases with the length of the rule

until the total length of the shrink rule exceeds that of the standard by

the amount of shrinkage per foot required.

FIGURE 165.

SHRINK RULES COMPARED TO STANDARD RULE.

217

Previous Page

Previous Page