USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 2/TASK 1

the handles are in perfect condition and always replace a defective handle

to avoid accidents.

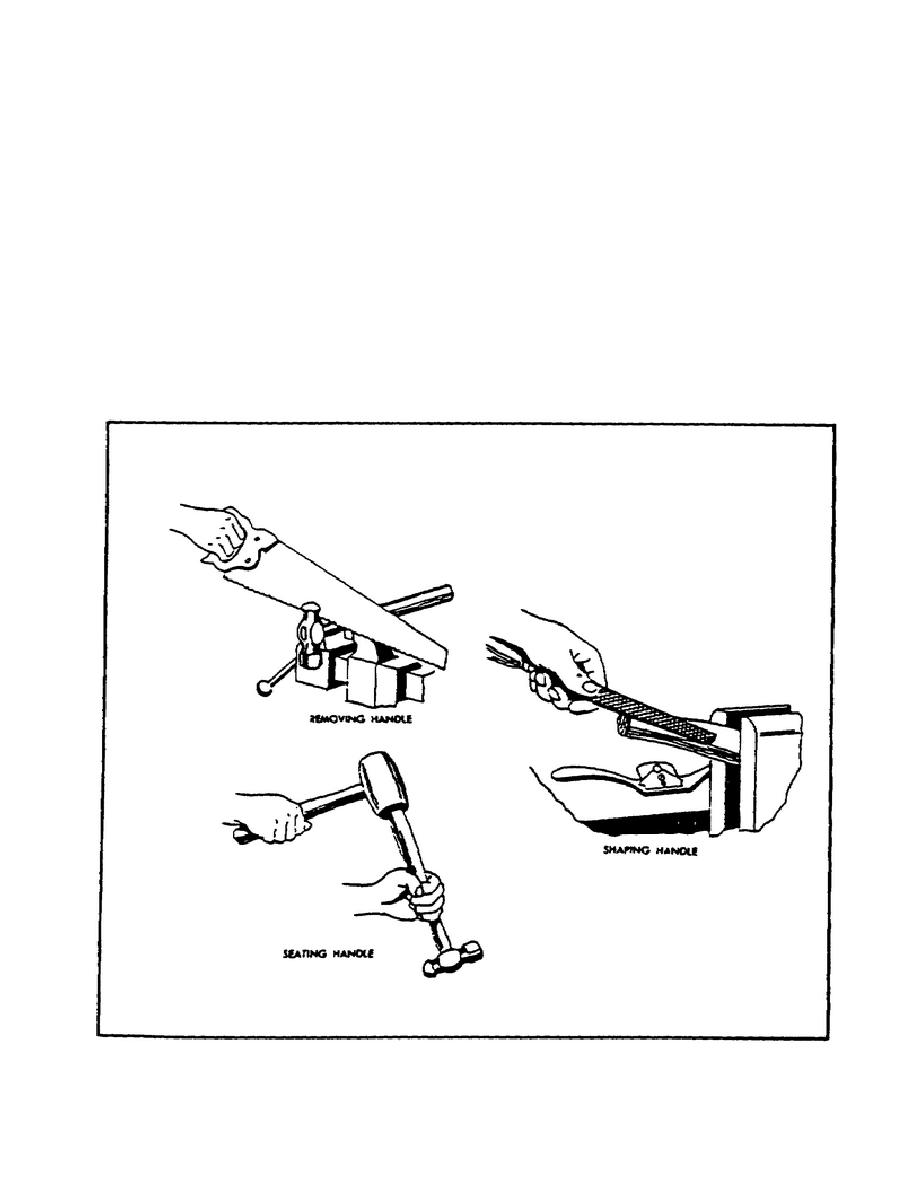

f. Repair and Replacement of Handles.

(1) Repair. Handles on hammers and sledge hammers must be inspected

constantly to see that they are tight and to check for split or broken wood.

If the handle is loose, seat it into the eye of the hammer head by striking

the end of the handle with a mallet (figure 4), and then drive the wedges

back into the handle.

If the wedges are not tight or do not spread the

handle sufficiently to make it tight, add another wedge or use larger

wedges, if possible.

In an emergency, a loose handle may be temporarily

tightened by soaking it in water until the wood swells within the head. If

the handle does not become tight, replace the handle.

FIGURE 4.

REPLACING HAMMER HANDLE.

19

Previous Page

Previous Page