PRIN. OF INTERNAL COMBUSTION ENGINES - OD1619 LESSON 1/TASK 1

(b) Reduces the contact area with the cylinder wall, which reduces friction.

(c) Allows the piston to be brought down closer to the crankshaft without

interference with its counterweights.

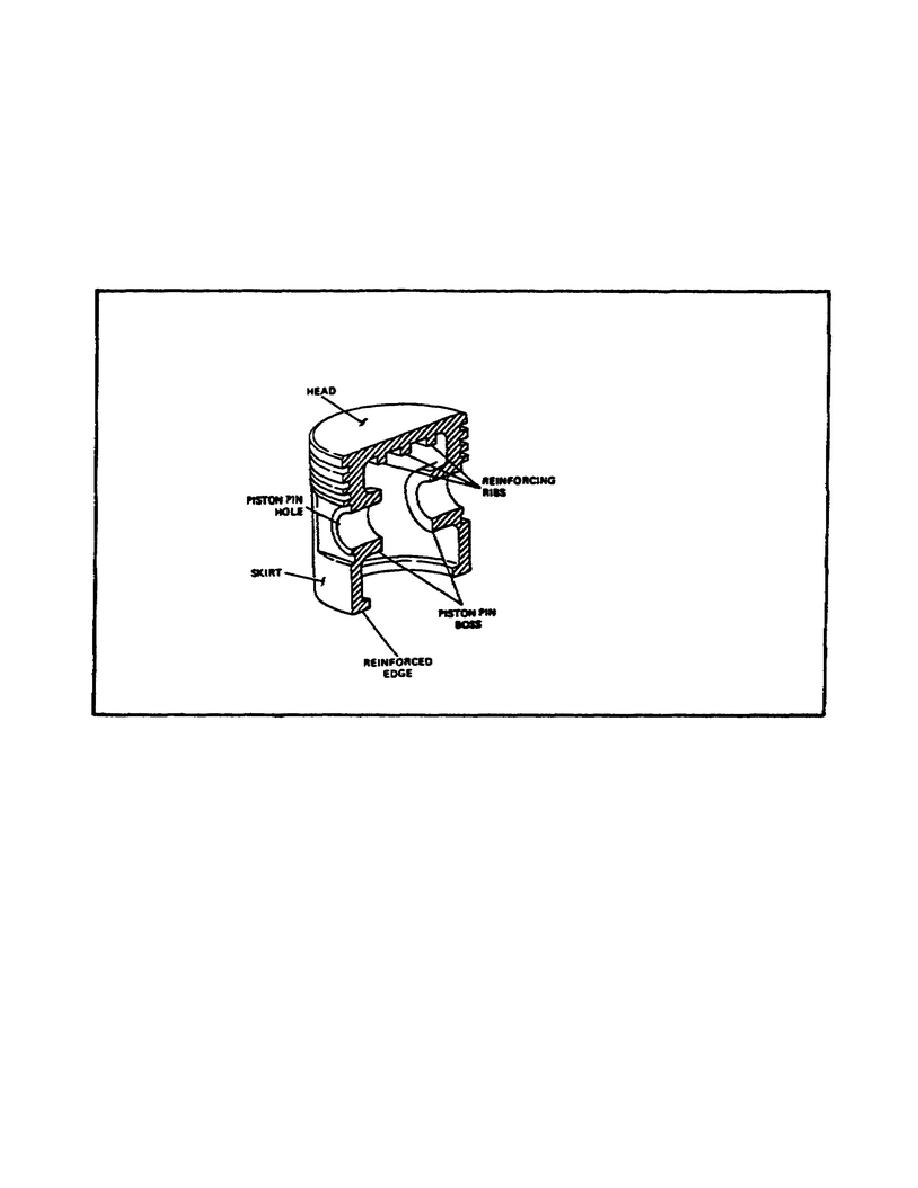

(6) Strength and Structure (figure 17 on the following page). When designing a

piston, weight and strength are critical factors. Two of the ways pistons are made

strong and light are as follows:

FIGURE 17.

PISTON STRUCTURE.

(a) The head of the piston is made as thin as is practical; to keep it strong

enough, ribs are cast into the underside of it.

(b) The areas around the piston pin are reinforced; these areas are called the

pin bosses.

(7) Coatings.

Aluminum pistons are usually treated on their outer surfaces to

aid in engine break-in and to increase hardness. The following are the most common

processes for treatment of aluminum pistons.

(a) The piston is coated with tin which will work into the cylinder walls as

the engine is broken in. This process results in a more perfect

19

Previous Page

Previous Page