PRINCIPLES GASOLINE/DIESEL FUEL SYSTEMS - OD1620 - LESSON 1/TASK 2

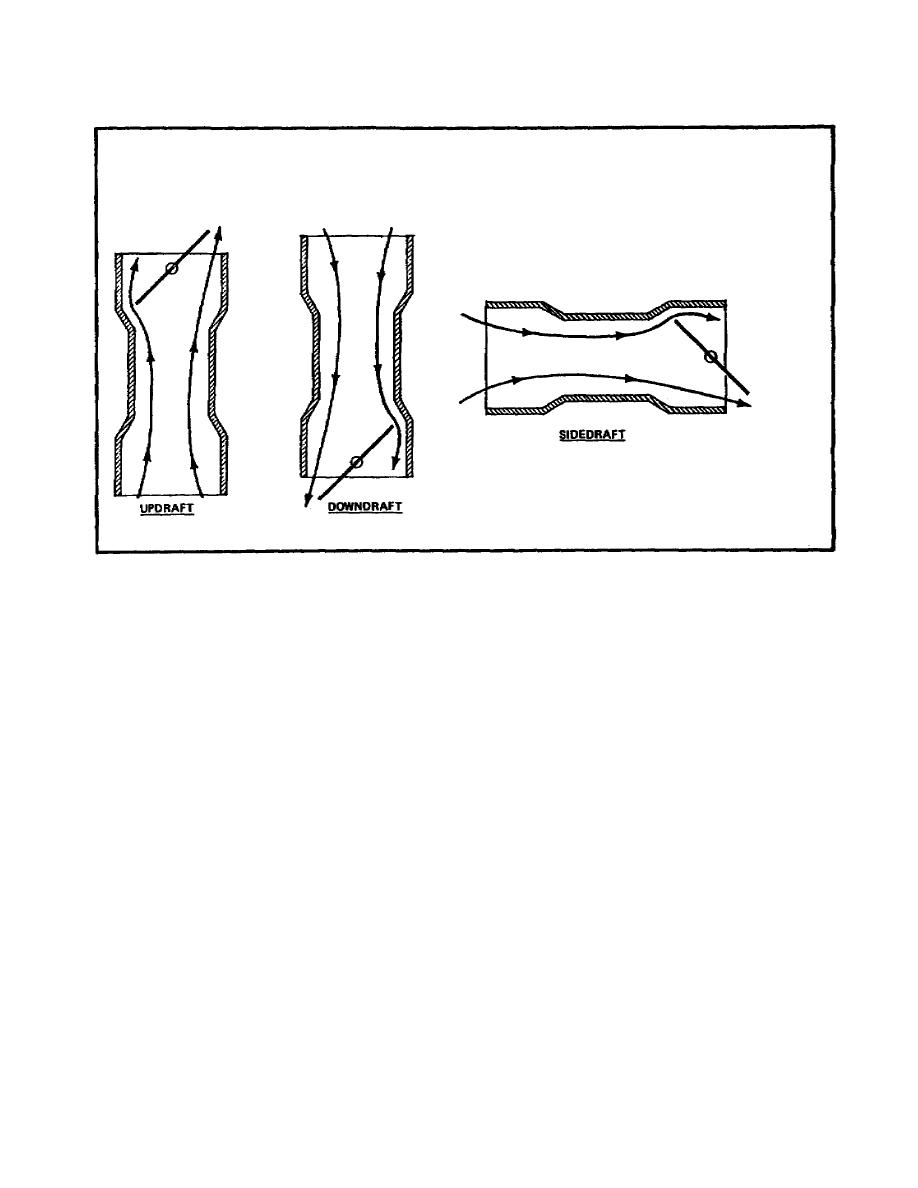

FIGURE 34. UPDRAFT, DOWNDRAFT, AND

SIDEDRAFT CARBURETORS.

i. Degasser System. The degasser system is designed to shut off the

supply of fuel to the idle circuit whenever there is high manifold vacuum,

such as periods of deceleration, preventing large amounts of fuel from being

drawn into the engine through the idle port. The degasser consists of a

needle valve, a spring that holds the needle valve open, and a vacuum

diaphragm that operates the needle valve through a fulcrum. The diaphragm

is operated by a manifold vacuum. During periods of normal engine idle, the

manifold vacuum is not high enough to operate the diaphragm and the needle

valve remains open. During periods of deceleration, the manifold vacuum is

high enough to cause the diaphragm to close the needle valve, shutting off

the idle system. The needle valve can also be closed by pushing a button on

the instrument panel to energize a solenoid, closing the needle valve. The

purpose of this manual actuation device is to clear the idle circuit and

manifold of unburned gases before the engine is turned off.

j. Accessory Systems. There are numerous devices that are used on

carburetors to improve driveability and economy. Their application varies

from vehicle to vehicle. The following paragraphs list the most common of

these devices.

47

Previous Page

Previous Page