PRIN. OF INTERNAL COMBUSTION ENGINES - OD1619 LESSON 2/TASK 1

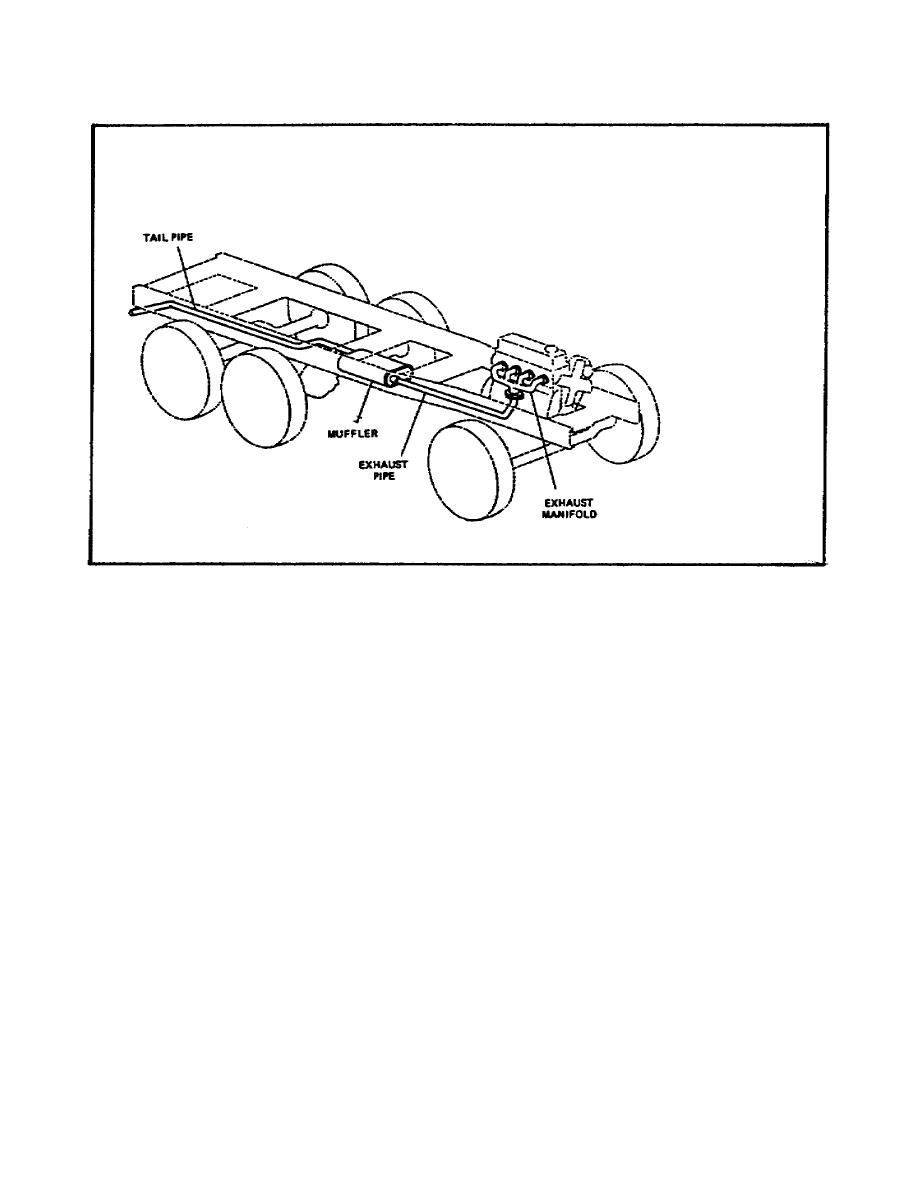

FIGURE 43. TYPICAL EXHAUST SYSTEM.

b. Exhaust Manifold (figure 44 on the following page). The exhaust manifold

connects all of the engine cylinders to the exhaust system and is usually made of

cast iron. If the exhaust manifold is formed properly, it can create a scavenging

action that will cause all of the cylinders to help each other get rid of exhaust

gases. Back pressure (the force that the pistons must exert to push out the

exhaust gases) can be reduced by making the manifold with smooth walls and without

sharp bends. All of these factors are taken into consideration when the exhaust

manifold is designed, and the best possible manifold is manufactured to fit into

the confines of the engine compartment.

c. Manifold Heat Control Valve (figure 45 on page 55). A valve is placed in the

exhaust manifold on some gasoline engines to deflect exhaust gases toward a hot

spot in the intake manifold until the engine reaches operating temperature. This

valve is a flat metal plate that is the same shape as the opening it controls. It

pivots on a shaft and is operated by a thermostatic coil spring. The spring pulls

the valve closed against a counterweight before warmup. The spring expands as the

engine warms up and the counterweight pulls the valve open.

53

Previous Page

Previous Page