Lesson 3/Learning Event 1

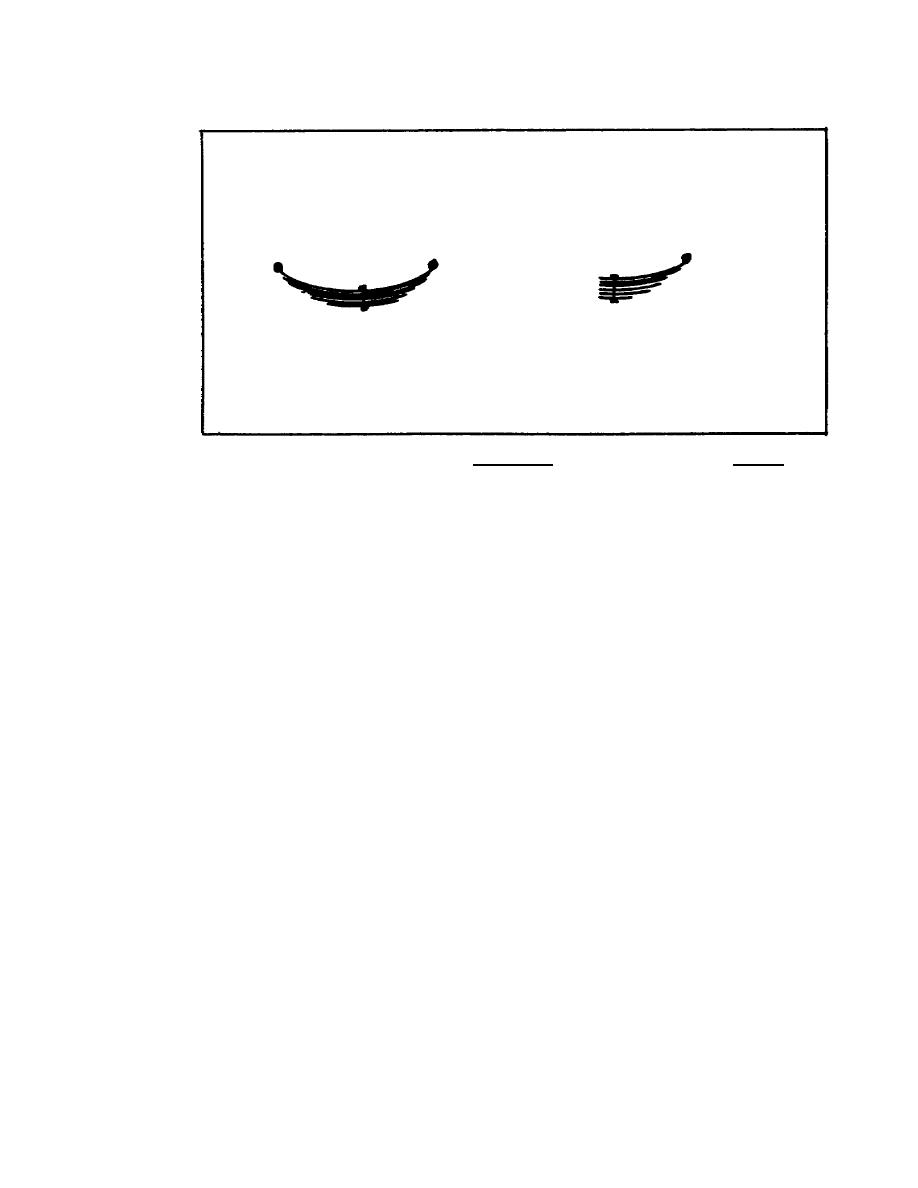

FIGURE 26. ELLIPTIC SPRINGS.

More variations of this spring are the semielliptic laminated leaf and the quarter elliptic

laminated leaf.

The semielliptic laminated leaf springs are the most commonly used on modern trucks

and on many passenger cars.

The semielliptic laminated leaf spring consists of several spring leaves of different lengths,

a center bolt, and spring leaf clips. The spring leaves are assembled according to length,

ranging from the shortest at one side to the longest at the other side of the spring. The

center bolt passes through a hole in the spring leaves and is secured with a nut. The

center bolt holds the spring leaves in place, and its head is generally engaged in the spring

seat to assist in axle alignment. The spring leaf clips are fitted around the spring, and

each one is secured with a bolt, spacer, and nut. The clips hold the ends of the leaves

together when the vehicle bounces over rough roads. They are often called rebound clips.

The ends of the first, or main, leaf are often rolled into circles that are called the spring

eyes. A bushing-type bearing is pressed into each spring eye. Usually, this is a smooth

brass or a bronze bushing, but sometimes it may be a rubber or threaded-steel type.

On light trucks, two semielliptic laminated leaf springs are generally used to mount each

axle assembly. The ends of each spring are fastened to the vehicle frame, lengthwise to

the vehicle. The axle assemblies are fastened to the springs at or near their centers. The

springs hold the axle assemblies in alignment with the vehicle frame.

54

Previous Page

Previous Page