Lesson 1

Construction and Operation

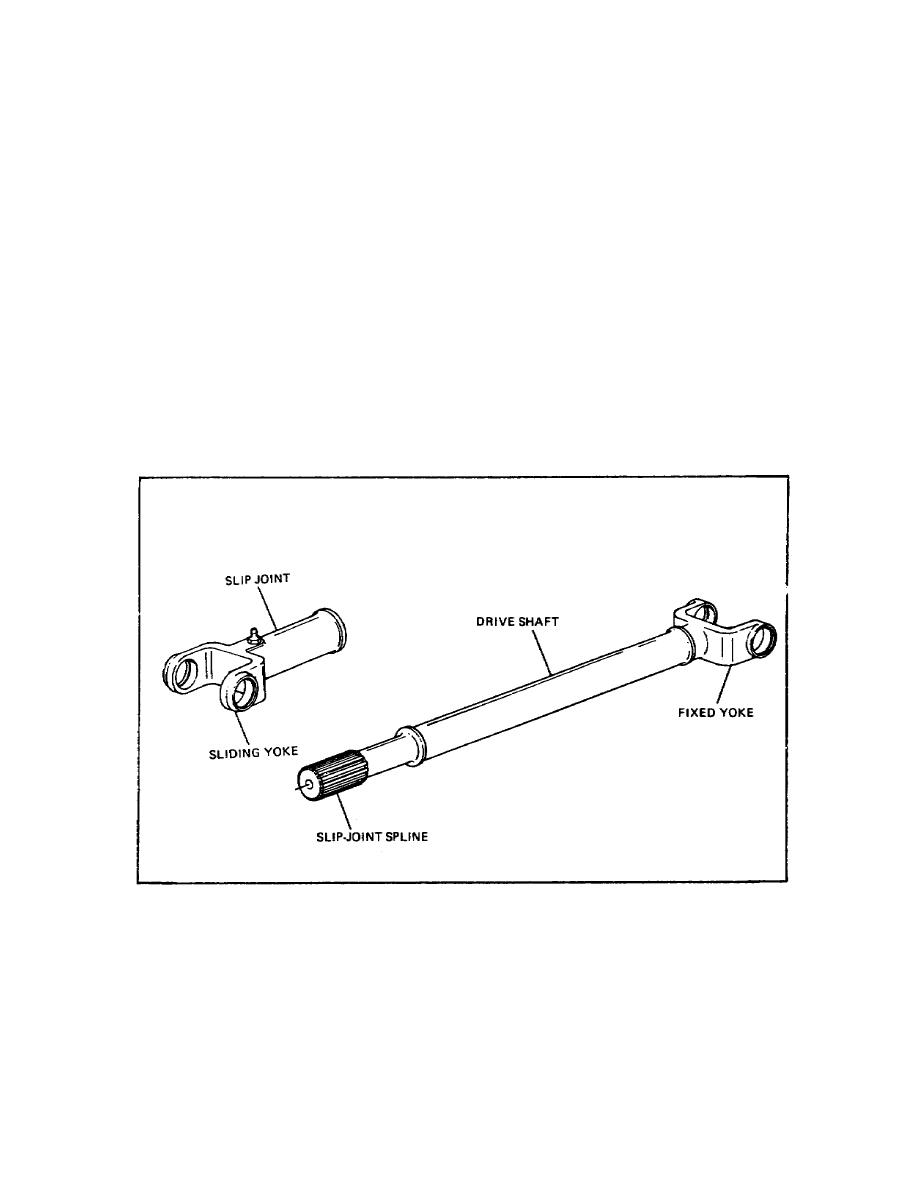

Propeller shafts are made in many different sizes, shapes, and strengths, depending on the

needs of the different types of vehicles. One end of the shaft is built to house a universal

joint. The other end is usually splined to a slip joint. The shafts may be made of solid

steel or may be hollow (tubular). A hollow propeller shaft is usually preferred.

The twisting force (torque) applied to one end of a shaft is transmitted through the shaft

to its opposite end. The strain (stress) created within the shaft ranges from a minimum

at the shaft's rotational center (axis) to a maximum at its outside surface. Since the

center part of a shaft carries only a small portion of the load, tubular (hollow) propeller

shafts are used whenever possible. A solid shaft is stronger than a tubular shaft of the

same thickness (diameter). A tubular shaft, however, is much stronger than a solid shaft

of the same weight and length.

FIGURE 2. AXLE ASSEMBLY.

The power transmission system must be flexible because of the springs in the vehicle's

suspension system. As the springs flex, the axle assemblies move backward and forward

and up and down. This causes the angles and distance between the axle assemblies and

the transfer case to constantly change. Slip joints and universal joints installed on

propeller shafts provide flexibility and permit these changes in the power transmission

system.

3

Previous Page

Previous Page