Lesson 1/learning Event 1

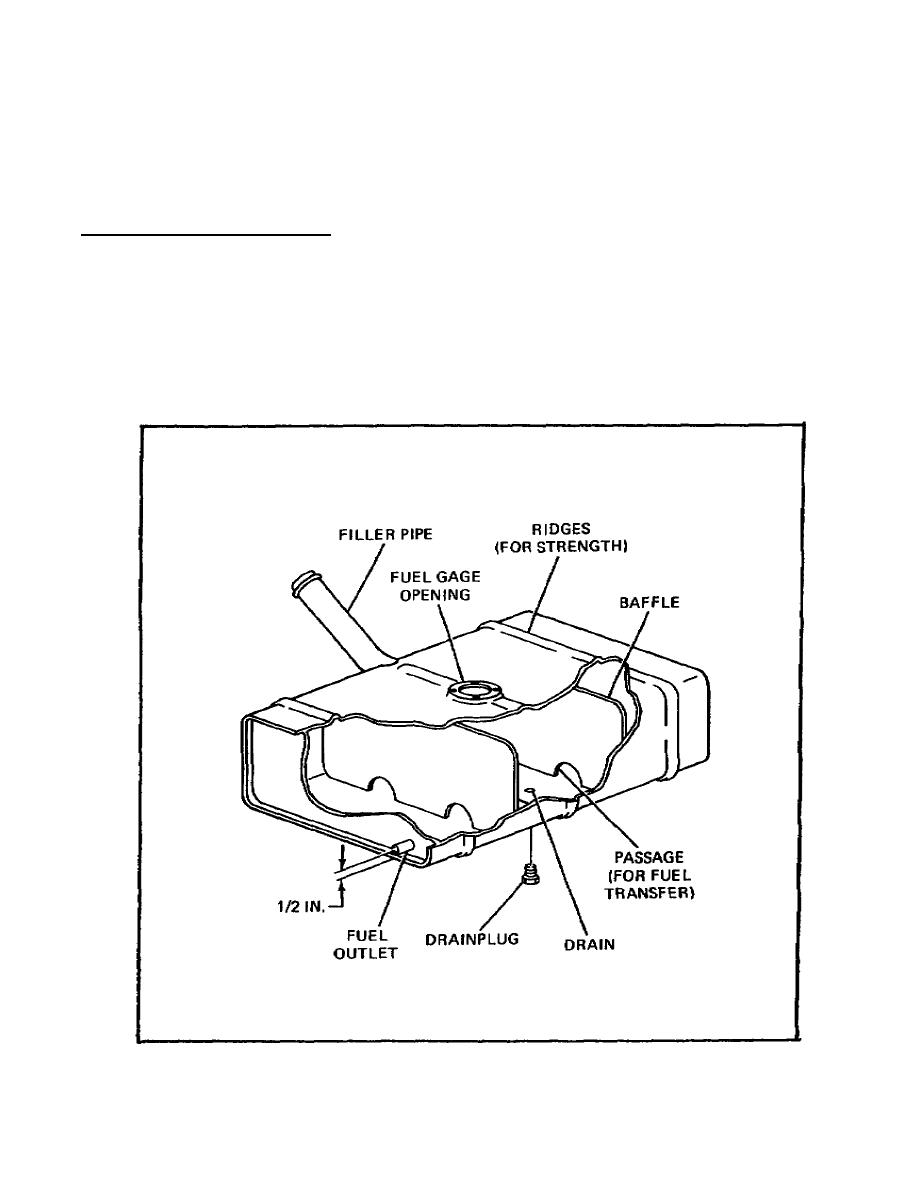

Most fuel tanks are made of thin steel sheet or plastic. The seams of the steel sheets are crimped or welded

to make the tank leakproof, and the tank is coated inside and out to prevent rust. The coating used is called

terneplate, an alloy of tin and lead.

Components of a Typical Fuel Tank

A funnel-shaped screen fits inside the filler neck on military vehicles to filter (strain) the gasoline before it

enters the tank. (Screens are not used in the fuel tanks of civilian vehicles.) The screen is easily removed

for cleaning.

On military vehicles, the fuel tank cap seals the filler neck when properly tightened. Military vehicles must

be able to ford bodies of water, so the filler neck and all other openings in the tank must be watertight.

FIGURE 1. TYPICAL REMOVAL FUEL TANK CONSTRUCTION.

The drain plug screws into a threaded hole in the sump (lowest point) of the tank. The drain plug can be

removed to flush out any water and foreign substances (trash) that may get into the tank.

2

Previous Page

Previous Page