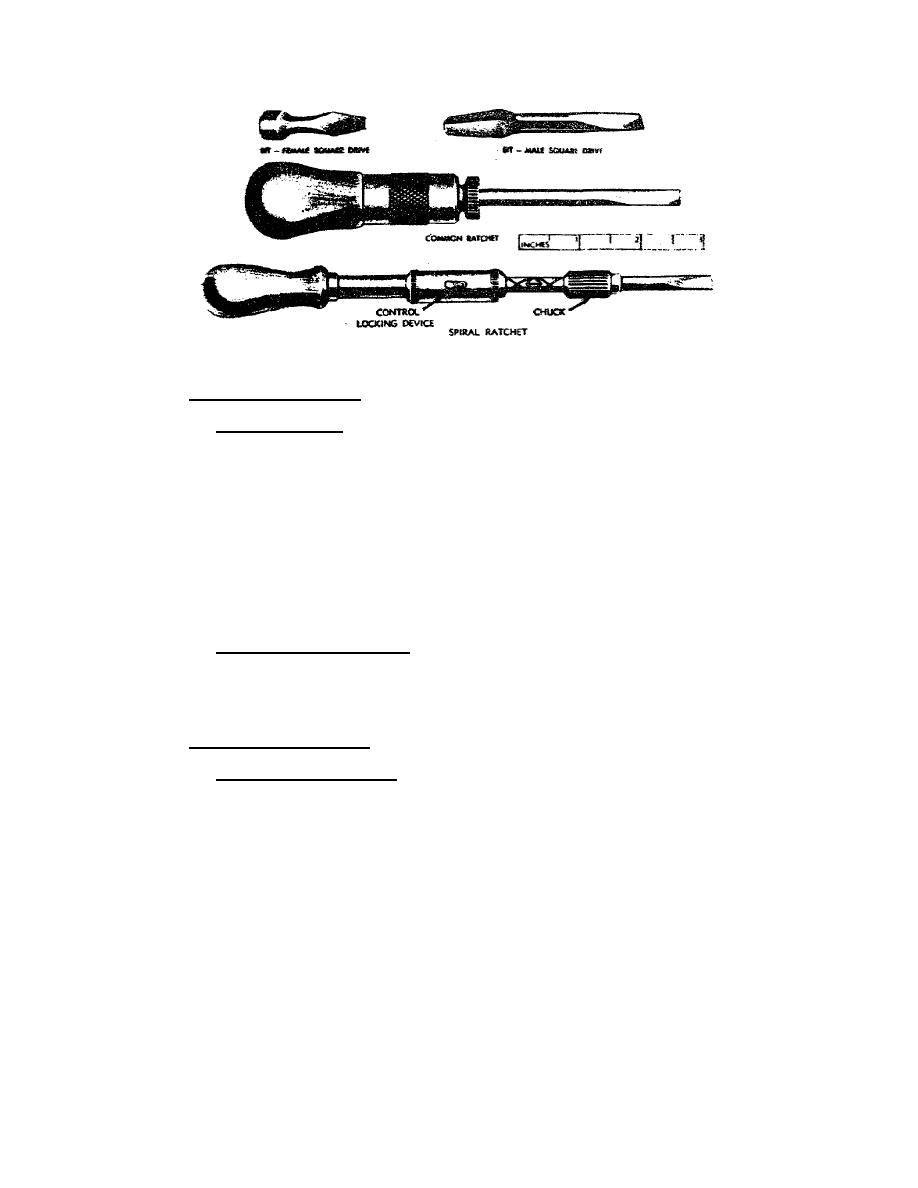

Figure 23.

Ratchet screwdrivers and screwdriver bits.

(8) Using a screwdriver.

(a) Driving screws. Use the longest screwdriver available which is

convenient for the work. The width of the tip should equal the length of the screw

slot and the tip must be thick enough to fit the width of the screw slot (fig 24).

Hold the handle firmly in one hand with the head of the handle against the palm and

grasp the handle near the ferrule with your thumb and finger (fig 25). Hold the

screwdriver in line with the axis of the screw and center the tip in the screw

slot. To drive screw in, press down with your palm and turn the screwdriver

clockwise (to the right). When taking a fresh grip on the handle, steady the tip

and keep it pressed in the screw slot with your other hand. Relax your other hand

when you are ready to turn the screwdriver again. To drive screws easier, rub a

little soap into the threads of a wood screw and put a drop of oil or a little

graphite on a machine screw. Doing this will also minimize the chances of rust

forming on the screws and will make them easier to remove.

(b) Removing tight screws.

When a screw cannot be turned at the first

attempt to remove it, try to tighten it first, then turn the screwdriver opposite.

Sequentially, tighten and loosen the screw until completely removed.

If a tight

screw with a damaged slot can be backed out partially, it is possible to remove it

completely with a pair of pliers.

(9) Care of screwdrivers.

(a) Dressing and shaping. When a screwdriver becomes nicked, or the

edges become rounded, or when other damage occurs so that it does not fit a screw

slot, it must be reground or filed. The sides must be parallel to keep the tool

from lifting from the screw slot, and the tip must be square and at right angles to

the sides and to the blade. If using a file, place the screwdriver in a vise.

When using a grinder, adjust the rest to hold the screwdriver against the wheel to

produce the desired shape, parallel or concave. Do not grind away more material

than necessary to remove nicks or square up the end. After squaring the tip, grind

both sides until the tip is the required thickness. Dip the screwdriver into water

frequently during grinding to prevent loss of temper by overheating. If the blade

discolors {blue or yellow), the temper has been damaged. Retemper by heating about

1-1/2 inches of blade to a cherry red with a torch. Immediately dip about 3/4 inch

of the blade in clean cold water. Quickly rub the hardened end with aluminum oxide

abrasive to brighten it. Watch the color creep back into the tip from the heated

portion of the blade. When the color becomes light blue, dip the blade into water.

The tip is now retempered and ready for use.

18

Previous Page

Previous Page