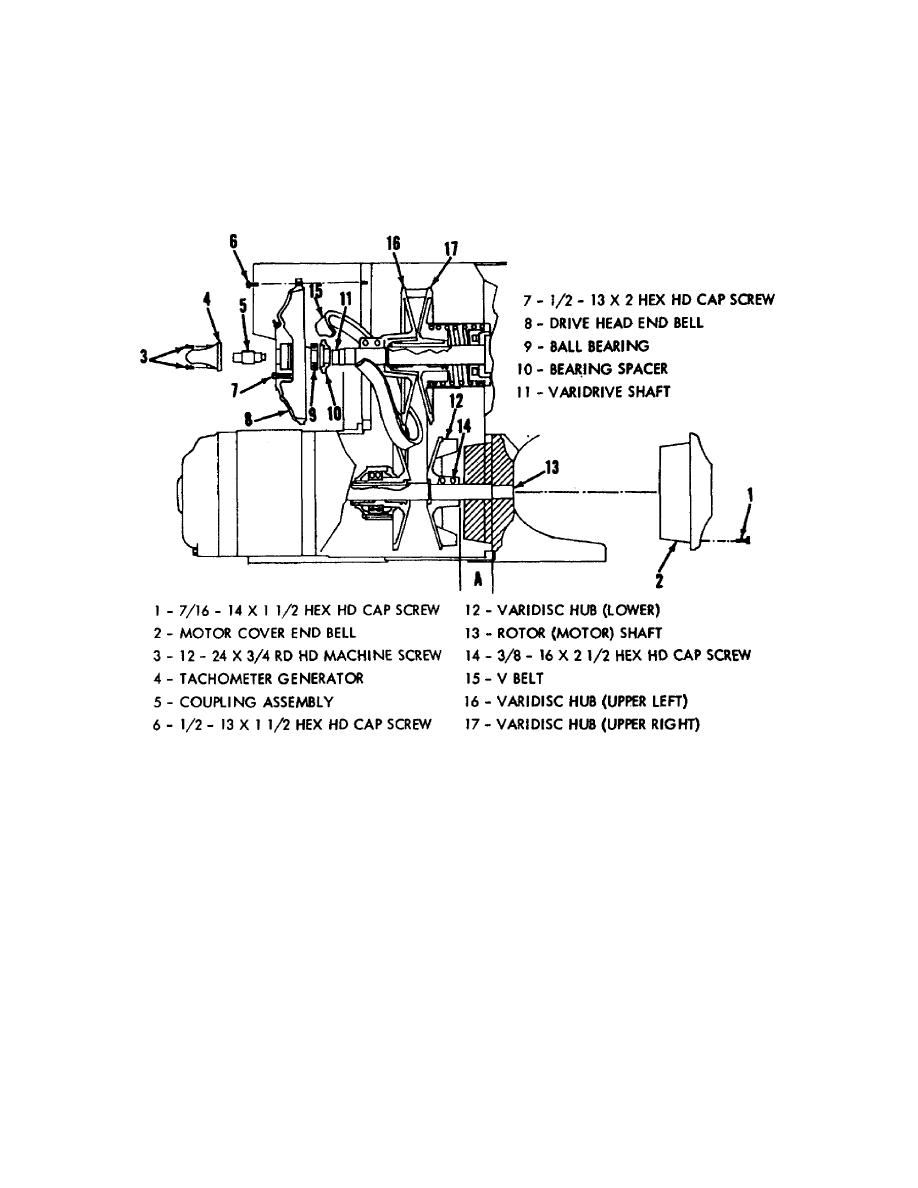

b. The varidrive assembly (fig 13) is shock-mounted to prevent control

panel vibration. A speed transmission and motor are embodied in this self-

contained unit. The front panel drive speed control allows the unit's RPM to be

varied over a wide range. Rotating the control counterclockwise causes the

moveable lower varidisc hub, mounted on the rotor (motor) shaft, to slide toward

its companion varidisc. The added tension on the V-belt causes the moveable

varidisc on the driven shaft to retract against the spring. This simultaneous

action causes the V-belt to assume a larger diameter on the lower varidisc and a

smaller diameter on the upper varidisc. The speed of the driven shaft is therefore

increased while motor speed remains constant.

Figure 13.

Varidrive and tachometer generator assembly.

c. We have previously discussed the tachometer indicator meter mounted on

the meter panel. That indicator is electrically connected to the tachometer

generator mounted on the end of the varidrive shaft. When the varidrive speed is

increased the direct current output of the generator increases, causing an up-scale

deflection on the tachometer. When the tachometer circuit is properly adjusted the

speed of either driving head can be read directly from the meter.

d. The electrical wiring diagram (fig 14) is included at this point so that

you can familiarize yourself with the location of all the components we have

discussed in this lesson. Locate the items discussed but do not study the diagram

extensively at this time. Selected circuits will be discussed in following lessons.

OS 010, 3-P16

Previous Page

Previous Page