LATHE OPERATIONS - OD1645 - LESSON 1/TASK 1

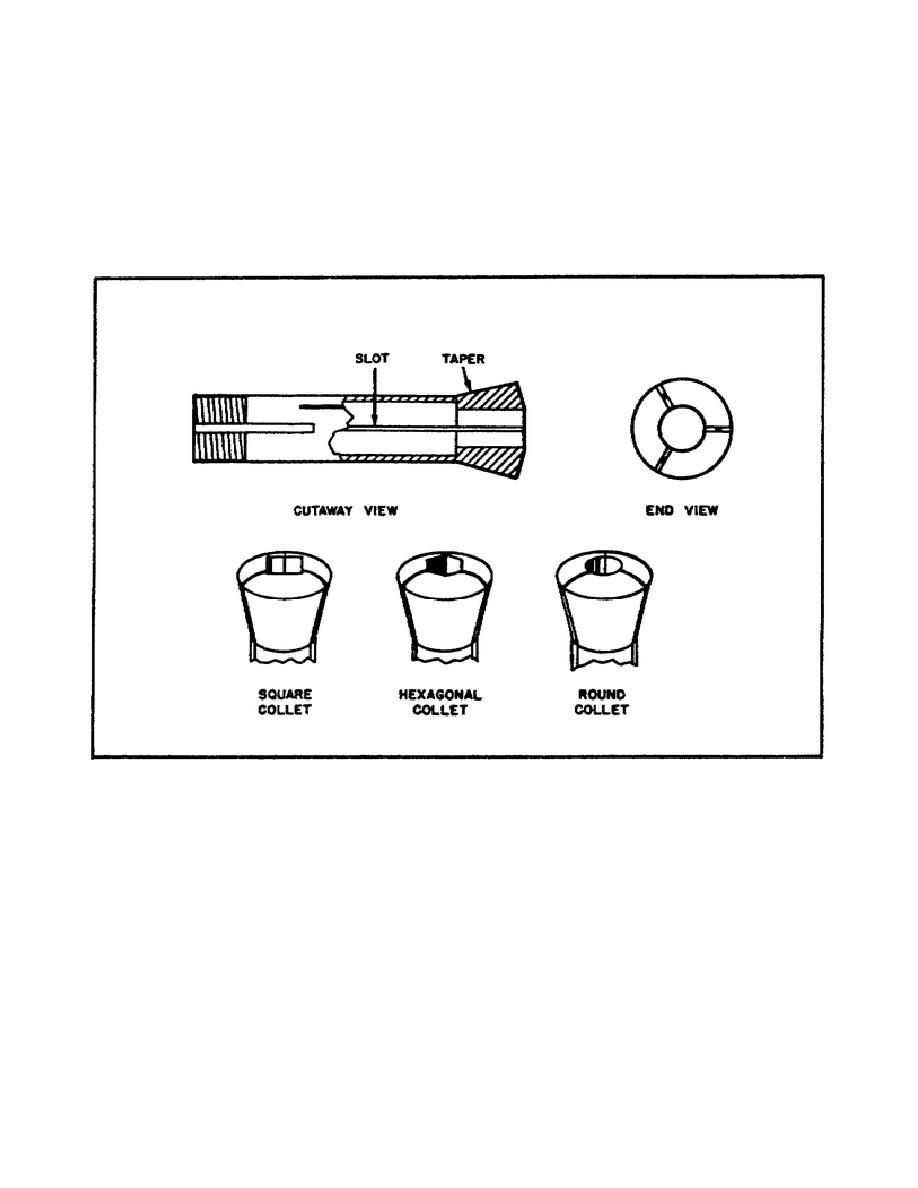

handwheel or hand lever to move the draw bar. The collet is fitted to the

right end of the headstock spindle.

The draw bar passes through the

headstock spindle and is threaded to the spring machine collet.

When the

draw bar is rotated by means of the handwheel, the collet is pulled inward

and the collet walls are cammed together by contact with the collet sleeve,

tightening the chuck to the workpiece.

FIGURE 15.

SPRING MACHINE COLLETS.

(d) Collet chucks are usually standard equipment on toolroom-type engine

lathes and on horizontal turret lathes.

Spring machine collets are

available in different shapes in order to chuck square and hexagonal

workpieces of small dimensions as well as round workpieces.

(8) Jacobs Rubber-Flex Collets. The rubber flex collet (figure 16 on the

following page) is comprised of hardened alloy steel jaws bonded together

with oil-resistant Hycar synthetic rubber. The collets have a range of 1/8

inch per collet and the gripping power and accuracy remain constant

throughout the entire collet capacity. These

34

Previous Page

Previous Page